Detachable scissors with locking mechanism

A technology of locking mechanism and scissors, applied in metal processing and other directions, can solve the problems of time-consuming installation and disassembly process, complicated assembly mechanism, etc., to achieve convenient assembly and disassembly, simple disassembly and assembly structure, and avoid the hidden danger of cutting personnel. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings.

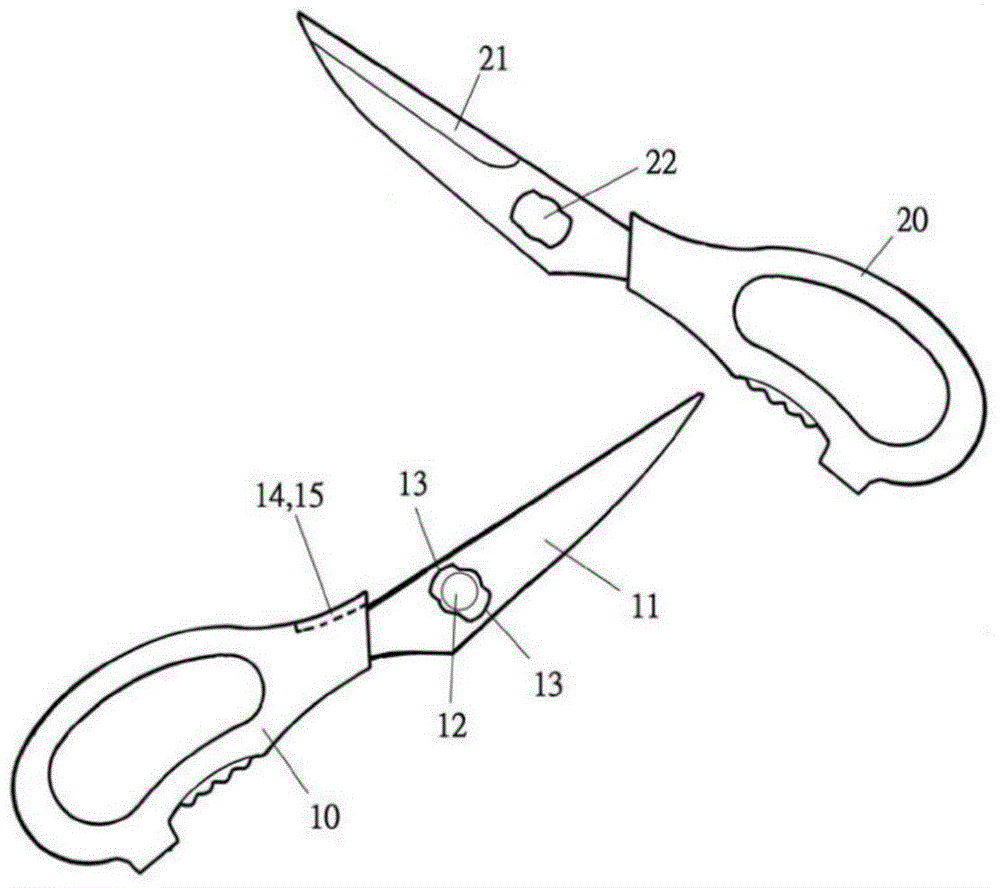

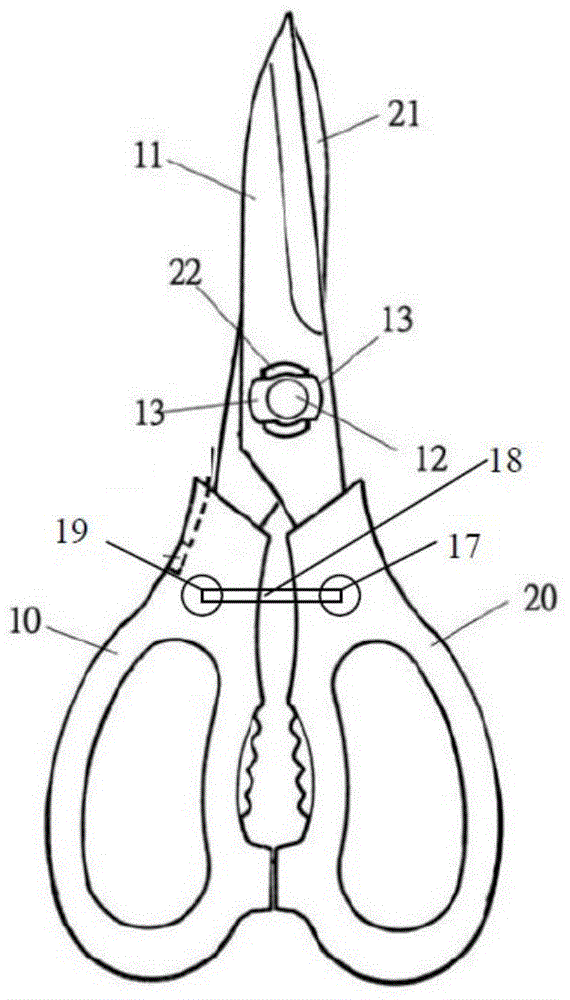

[0015] refer to figure 1 , figure 2 As shown, in this embodiment, as shown in the above drawings, the present invention mainly includes the first scissors body 10 and the second scissors body 20; wherein:

[0016] The first scissors body 10 has a first blade 11 on which a mounting rod 12 protrudes, and stop portions 13 protrude from both sides of the top end of the mounting rod 12 . In addition, a tenon portion 14 can be provided on the outer upper edge of the first scissors body 10 , and the tenon portion 14 is installed in a receiving space 15 .

[0017] Specifically, in this embodiment, the tenon part 14 can be manually inserted into the above-mentioned receiving space 15, and after the installation is completed, the exposed part is outside the above-mentioned receiving space 15. The length of the part outside the space 15 is betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com