Method and device for operating a motor vehicle, motor vehicle

A technology for motor vehicles and driving devices, applied in the directions of power plant, electric power plant, transportation and packaging, etc., can solve the problems of reducing braking force, heavy acceleration, etc., and achieve the effect of preventing the increase of vibration, the increase and the occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

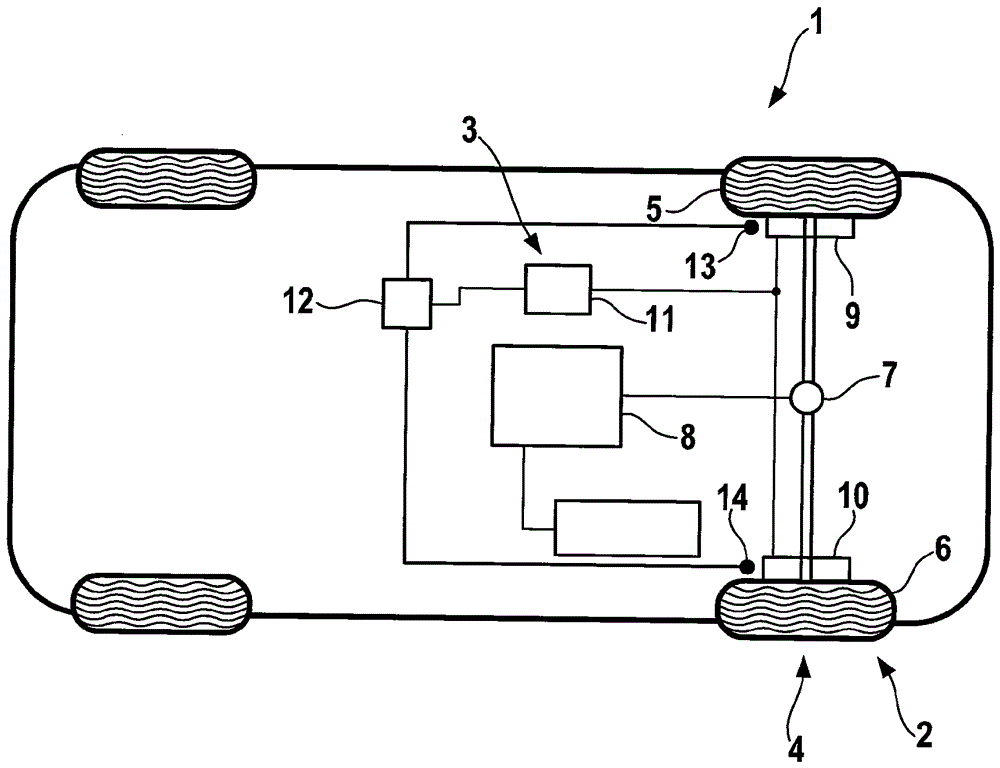

[0016] figure 1 A motor vehicle 1 is shown in a simplified top view, with a drive 2 and a braking system 3 .

[0017] The drive mechanism 2 has a drive shaft 4 with two drive wheels 5 , 6 , which are operatively connected to each other via a differential gear 7 . According to another exemplary embodiment not shown here, it can also be provided that the drive mechanism 2 can be decoupled from the drive shaft 4 by means of a clutch or the like. Furthermore, the differential gear 7 is coupled to an electric drive 8 .

[0018] Brake system 3 has wheel brakes 9 , 10 which are each assigned to one of drive wheels 5 , 6 . In particular, wheel brakes 9 , 10 can be actuated hydraulically. For this purpose, the brake system 3 has an antilock brake system 11 hydraulically connected to the wheel brakes 9 , 10 in order to hydraulically actuate the wheel brakes to generate a braking force. The antilock braking system 11 is designed here as an ABS braking system, which actuates the wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com