Construction method for small-spacing long-large underwater sheet steel pile cofferdams

A steel sheet pile cofferdam and construction method technology, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of consuming construction materials, increasing construction costs, and difficulties in earthwork excavation, so as to reduce construction costs, save construction period, and save temporary Effects of Structural Materials and Duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

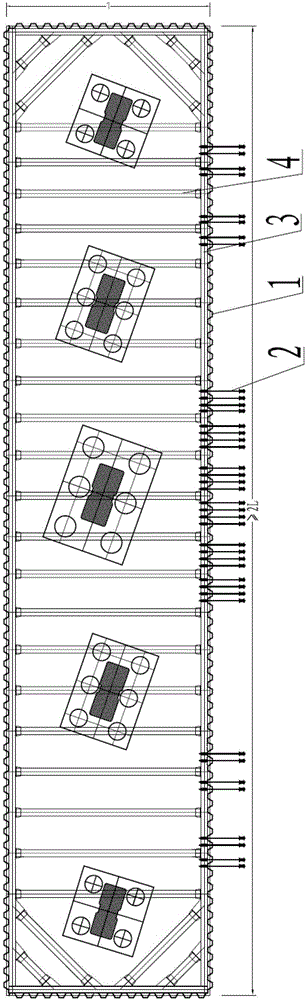

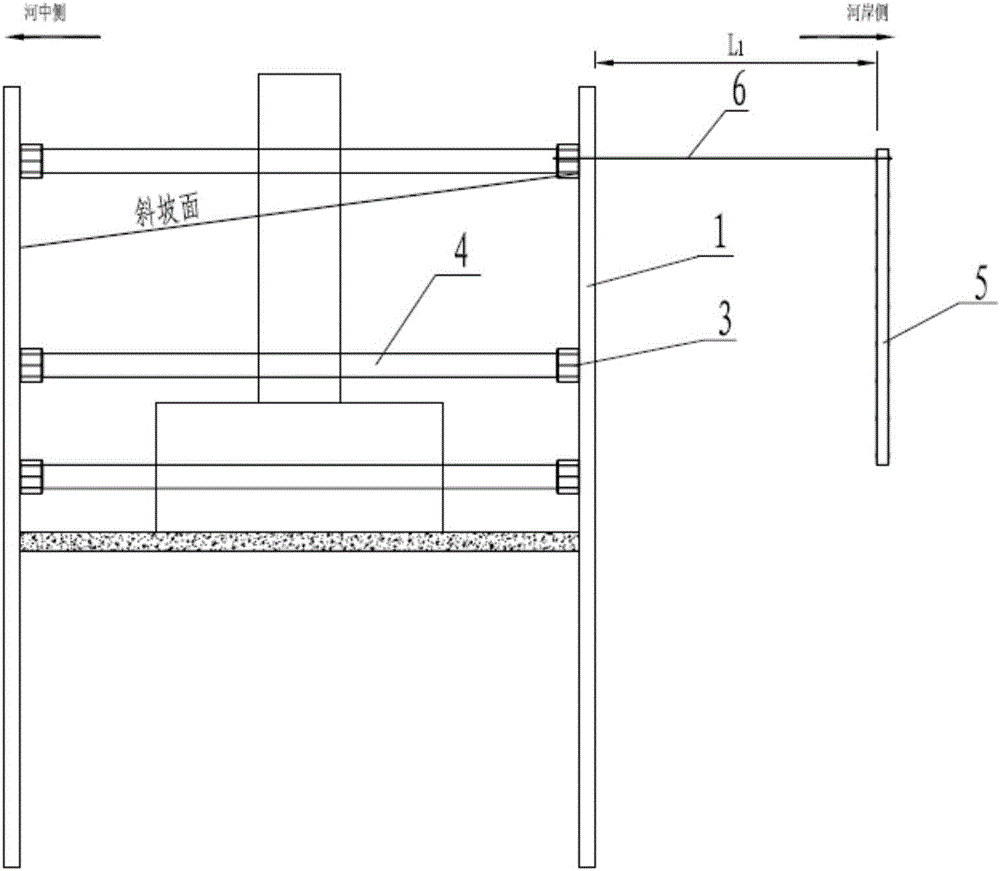

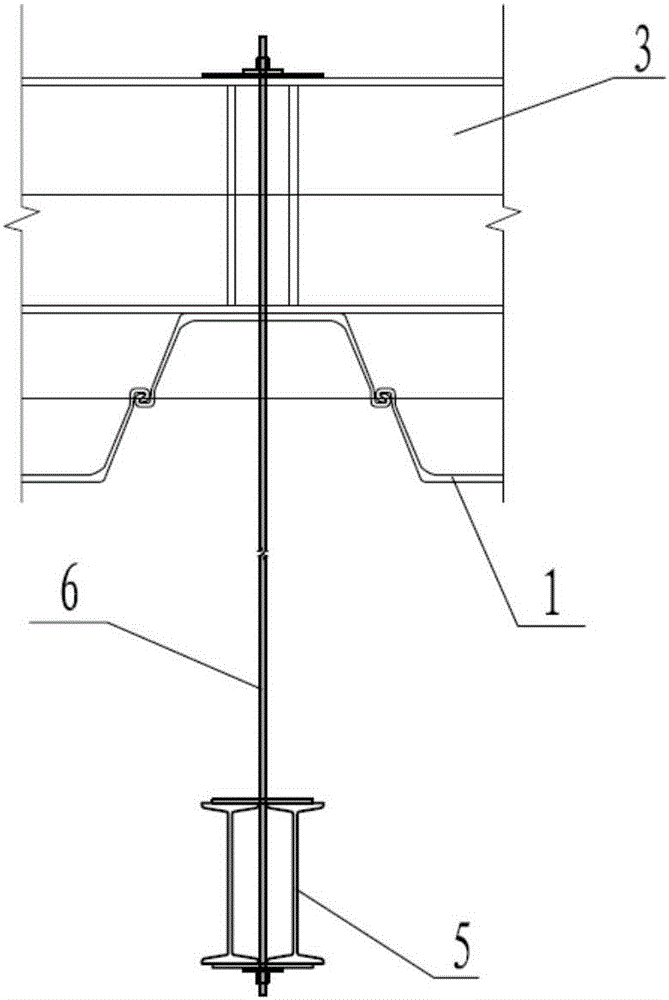

[0031] Referring to the accompanying drawings, the construction method of steel sheet pile cofferdams in small-space and long-distance water is applied on the soil layer on the inclined surface, which specifically includes the following steps:

[0032] ⑴Construction preparation

[0033] Check the mechanical equipment and steel sheet piles entering the site. All steel sheet piles that are bent, damaged, or locked must be repaired.

[0034] ⑵Water guide beam installation

[0035] Drive the steel pipe positioning piles into the four corners of the foundation pit and at intervals of 6m on each side; after the steel pipe positioning piles are inserted to the designed position, the section steel corbels are welded on the steel pipe positioning piles at a position 1m below the top of the steel sheet piles, and the corbels are welded For fixed section steel or steel sheet pile guide beams, in order to ensure the accuracy of the plane position of the steel sheet piles, two rows of st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com