Wall decoration process

A technology for wall decoration and craftsmanship, which is applied in covering/lining, architecture, building construction, etc., and can solve problems such as hidden safety hazards, large space occupation, and maintenance difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

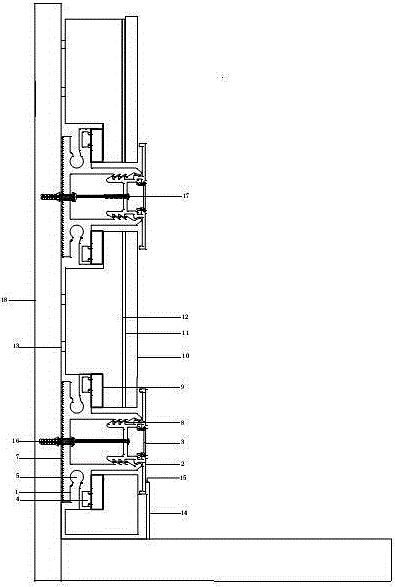

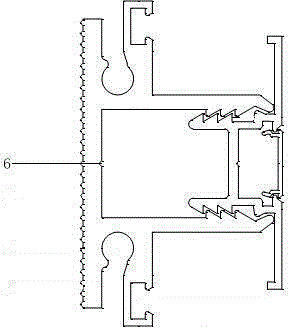

[0007] Such as figure 1 As shown, a wall decoration process is mainly composed of wall decoration profile 1, sheet outer clip, decorative process cover 3, adhesive strip bayonet 4, splicing bayonet 5, perforated positioning opening 6, non-slip tooth opening 7, Adjust the serration 8, double-sided tape 9, decorative surface layer 10, surface layer and EPS board bonding layer 11, insulation board 12, structural adhesive / 13, skirting 14, silicone sealant closing 15, plastic expansion plug 16 , The anti-dropping fixing screw 17 and the wall 18 are formed; the anti-slip tooth opening 7 is fixed on the wall 18 with the plastic expansion bolt 16 and the anti-dropping fixing screw 17 respectively, and the anti-slip tooth opening 7 is provided with a perforated positioning opening 6 and arranged There are adjustable serration ports 8, non-slip tooth ports 7 connected to wall decoration profile 1, wall decoration profile 1 is equipped with splicing bayonet 5, one side is equipped with adh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com