Fireproof lock for ship

A fire-proof lock, marine technology, used in building locks, buildings, building structures, etc., can solve the problems of no lock function, large volume, poor appearance, etc., to achieve a wide range of applications, simple structure, and generous appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

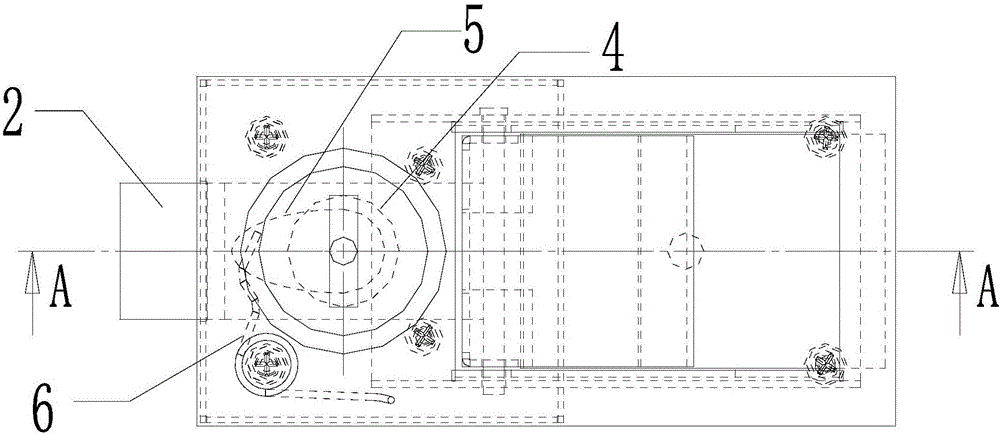

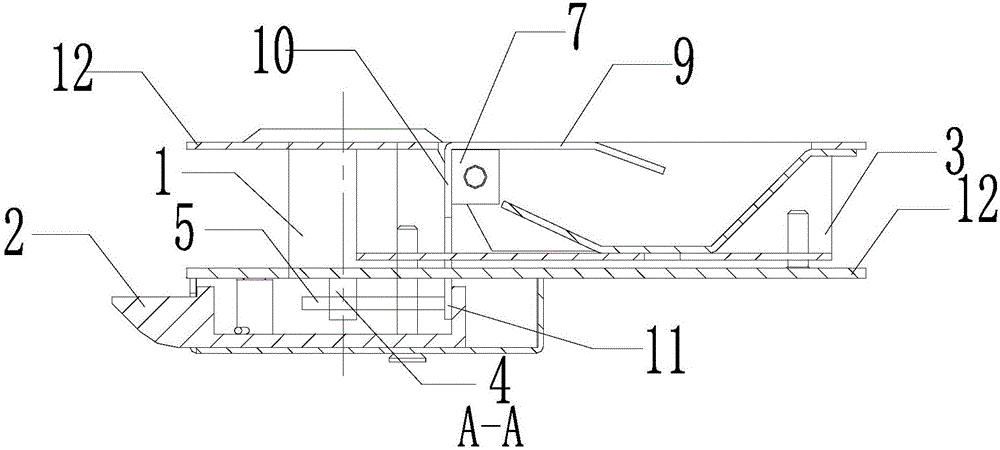

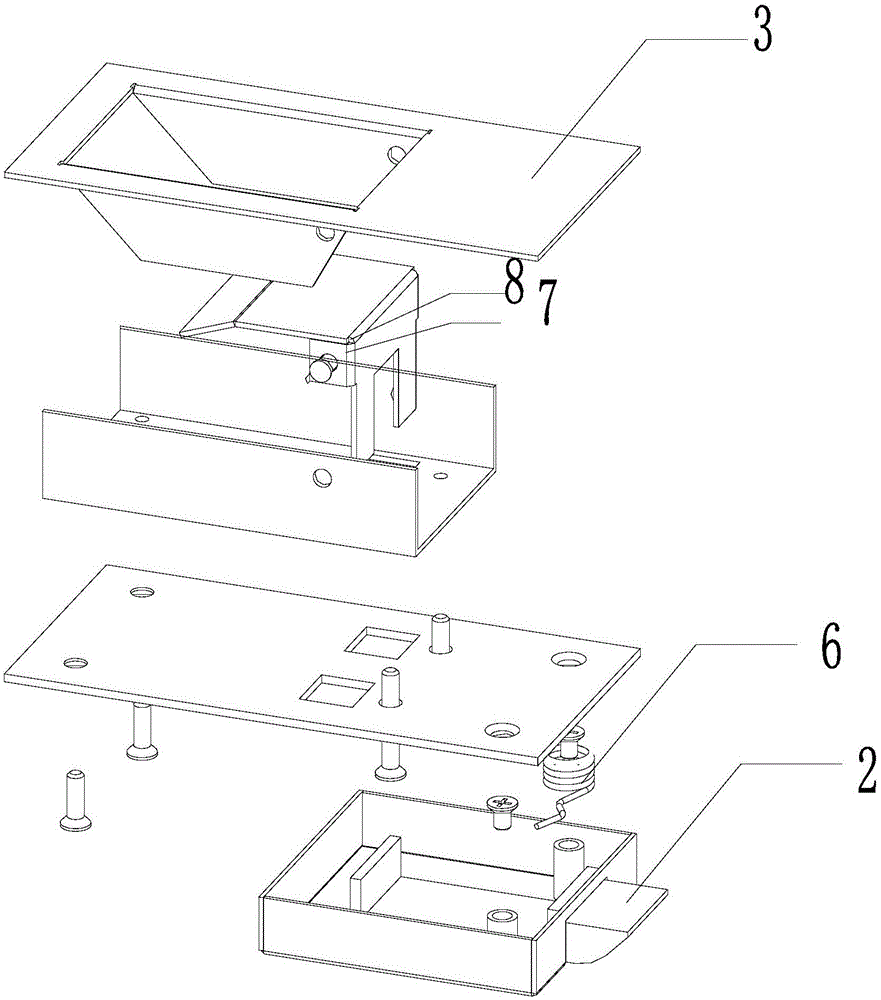

[0023] Example: Combine figure 1 , figure 2 , image 3 , a marine fireproof lock, including a lock cylinder 1, a lock tongue 2, a cam mechanism, and a handle 3; the cam mechanism includes a rotating shaft 4, a block 5, and a torsion spring 6.

[0024] The lock core 1 is located on the outside, and one end is provided with a key jack corresponding to the key, and one end is connected with the cam mechanism.

[0025] The dead bolt 2 is located on the inner side, and is a dead bolt 2 with a hollow in the middle to open the cavity. A cam mechanism is provided in the cavity of the dead bolt 2, and the dead bolt 2 is connected to the lock cylinder 1 through the cam mechanism, so as to realize from the key, the lock cylinder 1, and the cam. Mechanism to unlock control of deadbolt 2.

[0026] One end of the rotating shaft 4 is connected to the center of the lock cylinder 1, and the other end is connected to the center of the block 5; the block 5 is specifically a protruding shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com