Finished siding wall with metal structure and wooden decorative surface

A wood veneer and metal structure technology, which is applied in building structure, covering/lining, construction, etc., can solve the problem of high maintenance labor and cost of wooden siding board bumping corners, easy corner bumping of wood siding boards, and impact Problems such as construction quality, to achieve social and economic benefits, reduce artificial material consumption, and improve overall fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

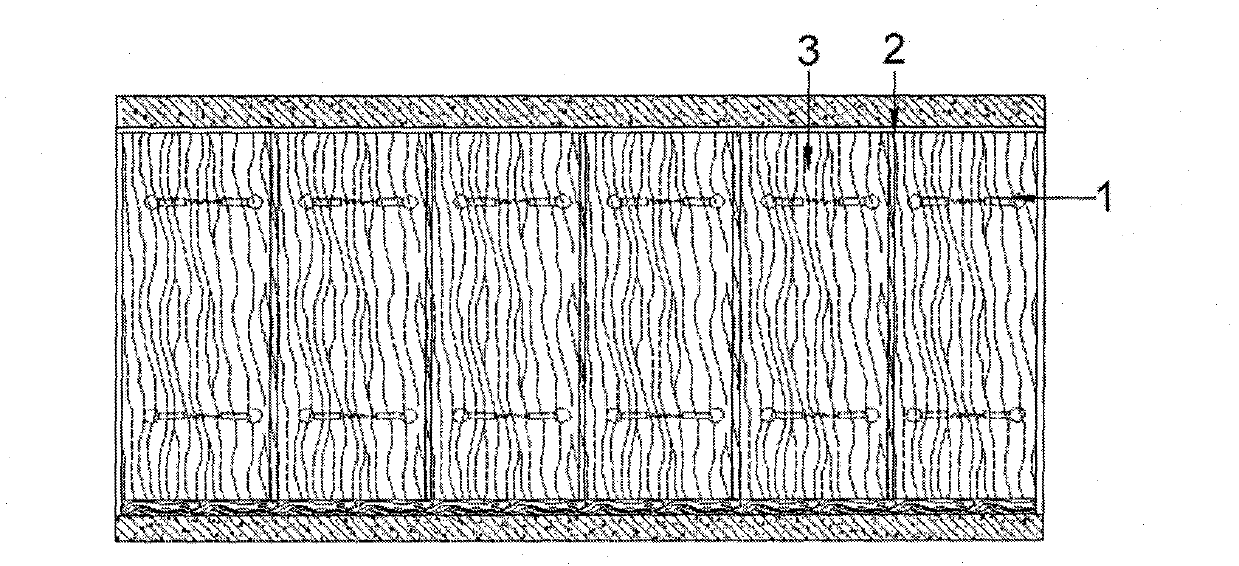

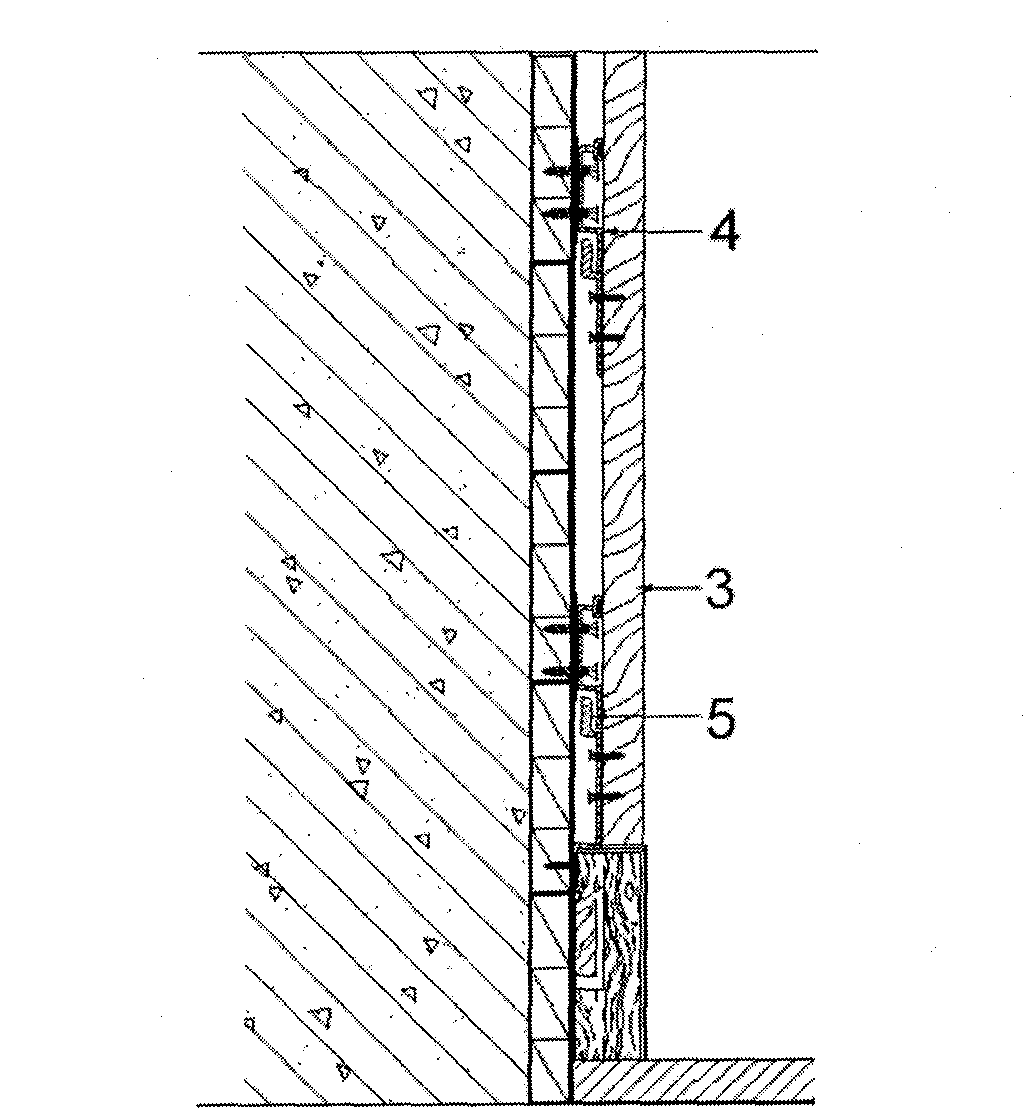

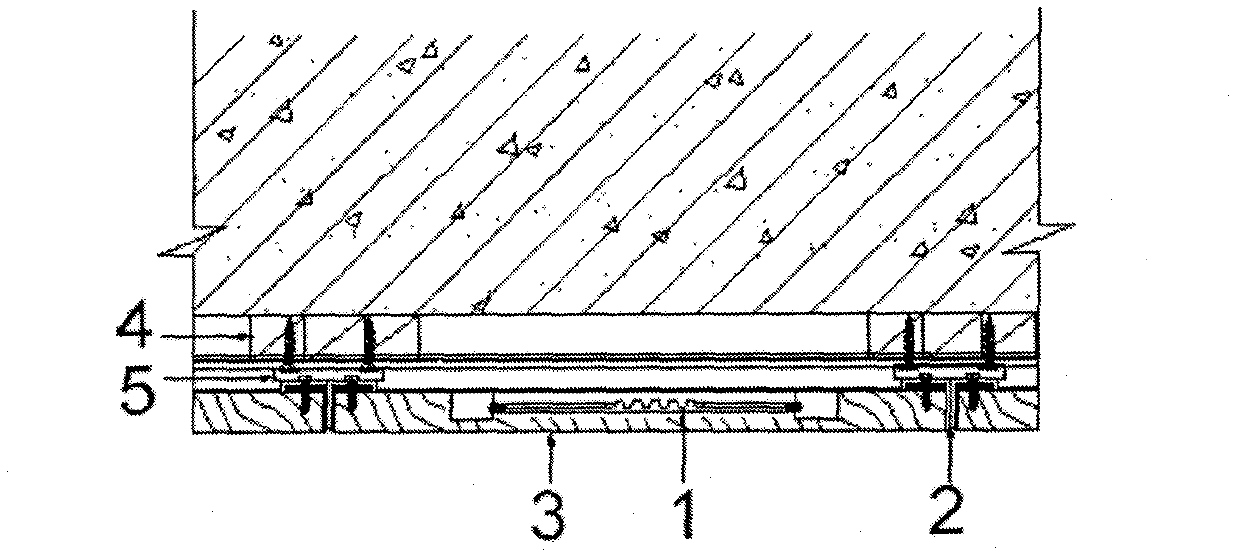

[0024] Example: such as figure 1 , figure 2 , image 3 As shown, a finished wood veneer panel wall with a metal structure includes a wood veneer 3, an aluminum hanging strip 5, and an aluminum hanging strip base 4 fixed on the wall.

[0025] The four sides of each unit of the wooden veneer 3 are aluminum alloy edge sealing 2, the back side of the wooden veneer 3 is provided with an aluminum hanging bar 5, and the notch of the aluminum hanging bar 5 is upward. The 4 notches of the base layer of the aluminum hanging bar are downward. The aluminum hanging bar 5 is cooperatively connected with the aluminum hanging bar base layer 4 .

[0026] The wood veneer 3 back is respectively distanced from the upper and lower ends of the wood veneer 3 at 200mm places to be provided with grooves, and the flat and consistent pull top strips 1 of the adjustable wood veneer 3 are respectively embedded in the grooves. The top bar 1 is an adjustable metal screw. The metal screw rod is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com