Composite insulation board without demolition and painting and its production process

A composite thermal insulation and paint-free technology, which is applied in the direction of thermal insulation, synthetic resin layered products, layered products, etc., can solve the problems of complex thermal insulation template process, long production cycle, high cost of secondary decoration, etc., and achieve anti-seepage and stability The effect is good, the product quality is guaranteed, and the overall performance is excellent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

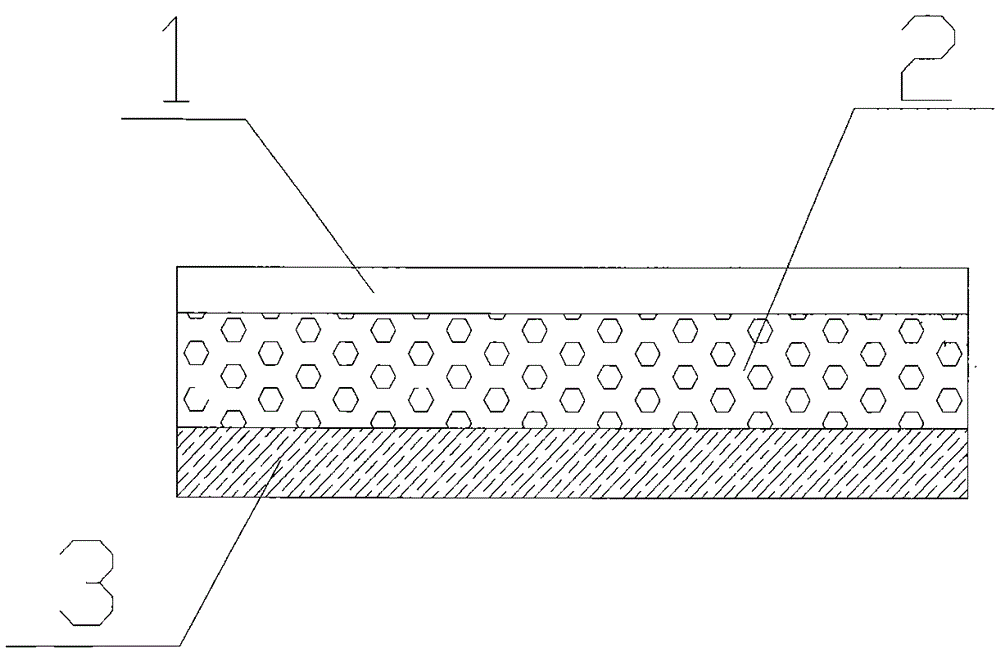

[0085] A production process for a non-dismantling and non-painting composite thermal insulation board, comprising the following steps:

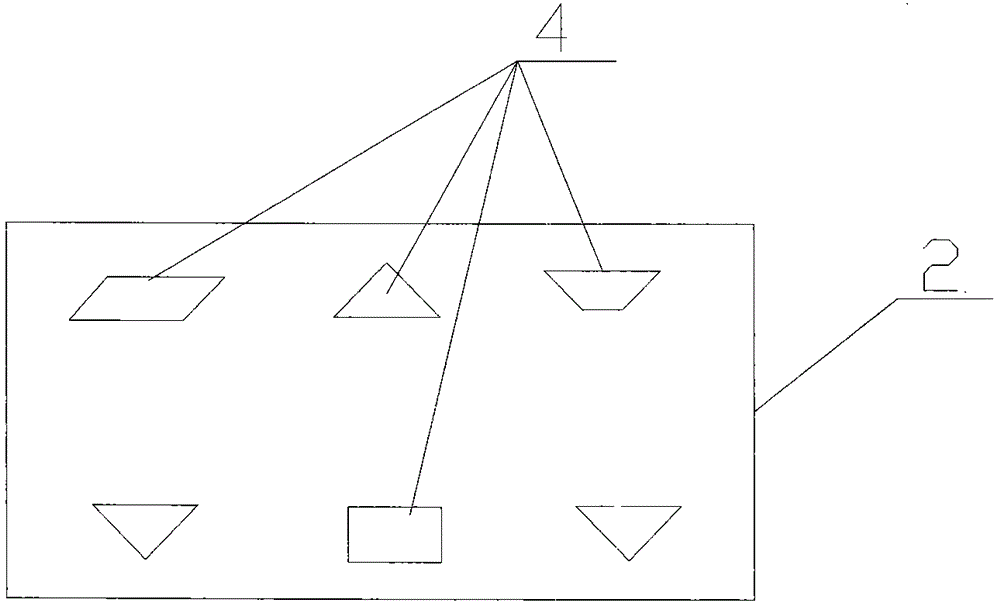

[0086] Step 1: fixing several fixing reinforcing strips 4 on the upper surface of the lower calcium silicate board 3 by nailing;

[0087] Step 2: Put the lower calcium silicate board 3 with several fixed reinforcing belts 4 in step 1 into the bottom layer laying station through the feeding conveying device, and heat the surface layer by the electric heating tube at a heating temperature of 30 ℃;

[0088] Step 3: prepare the melting material of the middle layer 2, the melting material of the middle layer 2 is a polyurethane casting material, and the polyurethane casting material is made by foaming a white material combination material and a black material, and the white material combination material includes the following raw materials by weight The number of parts is made after foaming: 50 parts of base materials, 0.2 parts of triethylenedia...

Embodiment 2

[0095] A production process for a non-dismantling and non-painting composite thermal insulation board, comprising the following steps:

[0096] Step 1: Fix several fixing reinforcing strips 4 on the upper surface of the lower calcium silicate board 3 by bolts;

[0097] Step 2: Put the lower calcium silicate board 3 with several fixed reinforcing belts 4 in step 1 into the bottom layer laying station through the feeding conveying device, and heat the surface layer by the electric heating tube at a heating temperature of 100 ℃;

[0098] Step 3: prepare the melting material of the middle layer 2, the melting material of the middle layer 2 is a polyurethane casting material, and the polyurethane casting material is made by foaming a white material combination material and a black material, and the white material combination material includes the following raw materials by weight The number of parts is made after foaming: 100 parts of base material, 0.8 parts of triethylenediamine...

Embodiment 3

[0105] A production process for a non-dismantling and non-painting composite thermal insulation board, comprising the following steps:

[0106] Step 1: Fix several fixing reinforcing strips 4 on the upper surface of the lower calcium silicate board 3 with glue;

[0107] Step 2: Put the lower calcium silicate board 3 with several fixed reinforcing belts 4 in step 1 into the bottom layer laying station through the feeding conveying device, and heat the surface layer by the electric heating tube at a heating temperature of 65 ℃;

[0108] Step 3: prepare the melting material of the middle layer 2, the melting material of the middle layer 2 is a polyurethane casting material, and the polyurethane casting material is made by foaming a white material combination material and a black material, and the white material combination material includes the following raw materials by weight The number of parts is made after foaming: 75 parts of base material, 0.5 part of triethylenediamine s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com