Locker

A locking device and connecting rod technology, applied in aircraft, motor vehicles, transportation and packaging, etc., can solve the problem that the locking device is easy to bump against the lower layer equipment in the cabin, and achieve convenient installation, reduce the swing angle, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

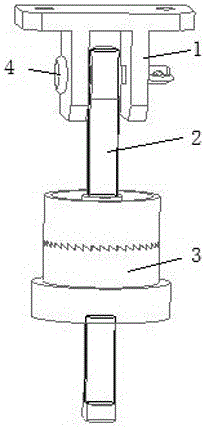

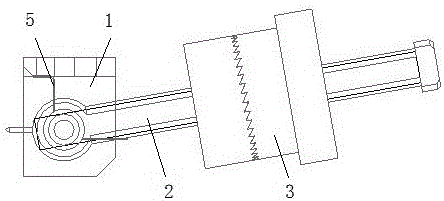

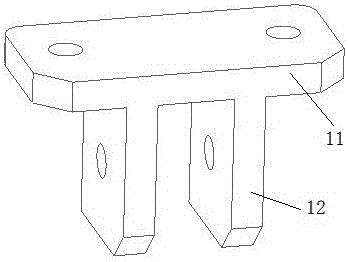

[0022] Specific embodiment 1 of the locking device of the present invention, such as Figure 2 to Figure 5 As shown, the locking device includes a hinge base 1, a connecting rod 2, a locking knob 3, a pin shaft 4 and a torsion spring 5, wherein the axis of the pin shaft 4 extends along the left and right directions, and the hinge base 1 includes a top plate 11 and a fixed The two ear plates 12 on the lower side of the top plate are correspondingly provided with perforations for the pin shaft 4 to wear; in this embodiment, the torsion spring 5 is a double torsion spring structure, and the torsion spring 5 includes a first spring body 50, The second spring body 51, the first connecting rod that one end links to each other with the first spring body, the second connecting rod that one end links to each other with the second spring body, and the U-shaped bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com