Multi-joint crank drive of an internal combustion engine and corresponding internal combustion engine

A technology of crank transmission and internal combustion engine, which is applied in the direction of machine/engine, engine control, engine components, etc., which can solve problems such as large distances and achieve the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

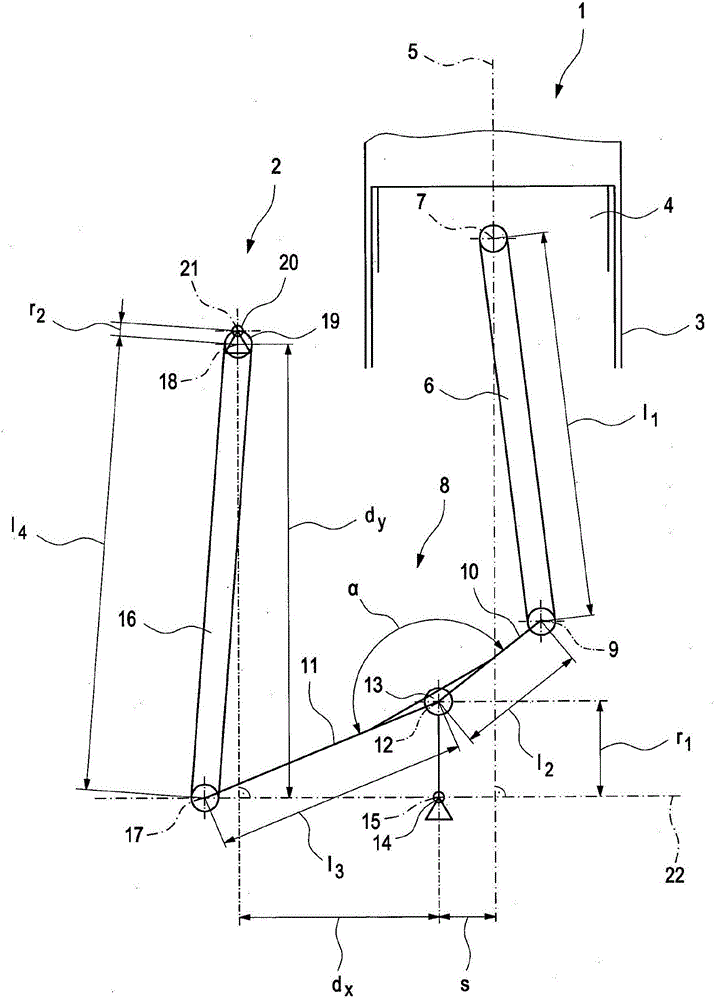

[0033] The figure shows a detail of an internal combustion engine 1 with a multi-link crank drive 2 . Internal combustion engine 1 also has at least one piston 4 arranged longitudinally movable in cylinder 3 . Cylinder 3 and piston 4 have a longitudinal center axis 5 . A piston connecting rod 6 is connected to the piston 4 , on which the piston connecting rod is mounted rotatably about a piston axis of rotation 7 . The piston axis of rotation 7 preferably lies here on the longitudinal center axis 5 of the cylinder 3 .

[0034] The piston rod 6 is connected on its side facing away from the piston 4 to a coupling part 8 . In this case, the piston rod 6 is mounted on the coupling part 8 so as to be rotatable about the piston rod axis of rotation 9 . The piston rod 6 is connected in particular to the first arm 10 of the coupling part 8 . The first arm and the second arm 11 are rigidly connected to each other and form an angle α. The angle α exists here about the coupling axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com