Sealing structure for seal valve

A sealing structure and sealing valve technology, which is applied to valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of sealing surface leakage, medium sealing side and outer ring leakage, etc., so as to strengthen the sealing ability and improve the sealing effect , fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Independent claim 1 describes a sealing structure for sealing valves,

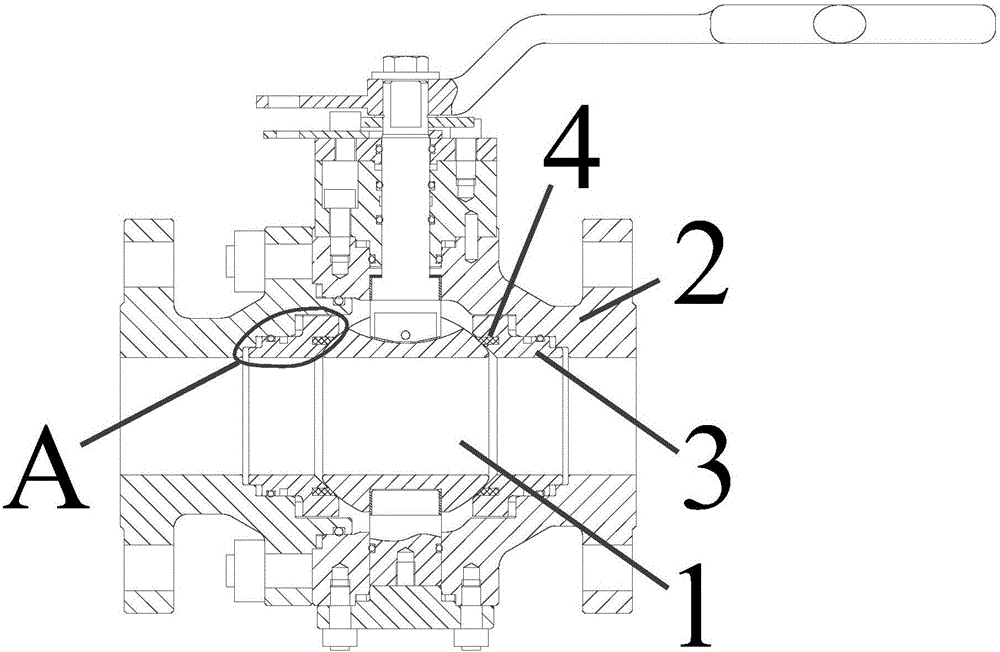

[0054] like figure 1 As shown, the sealing valve includes: a valve core 1, a valve body 2, and a retainer 3 arranged between the valve core 1 and the valve body 2, the above-mentioned valve core 1 is a spherical valve core; the sealing structure includes:

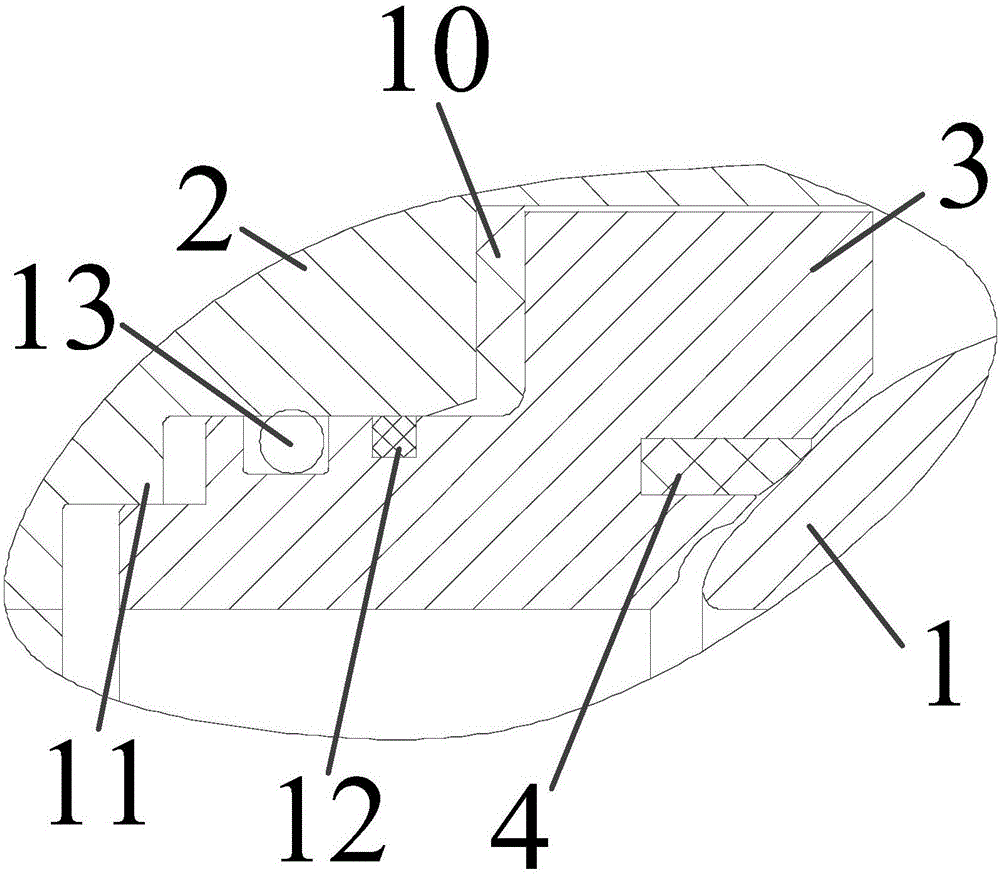

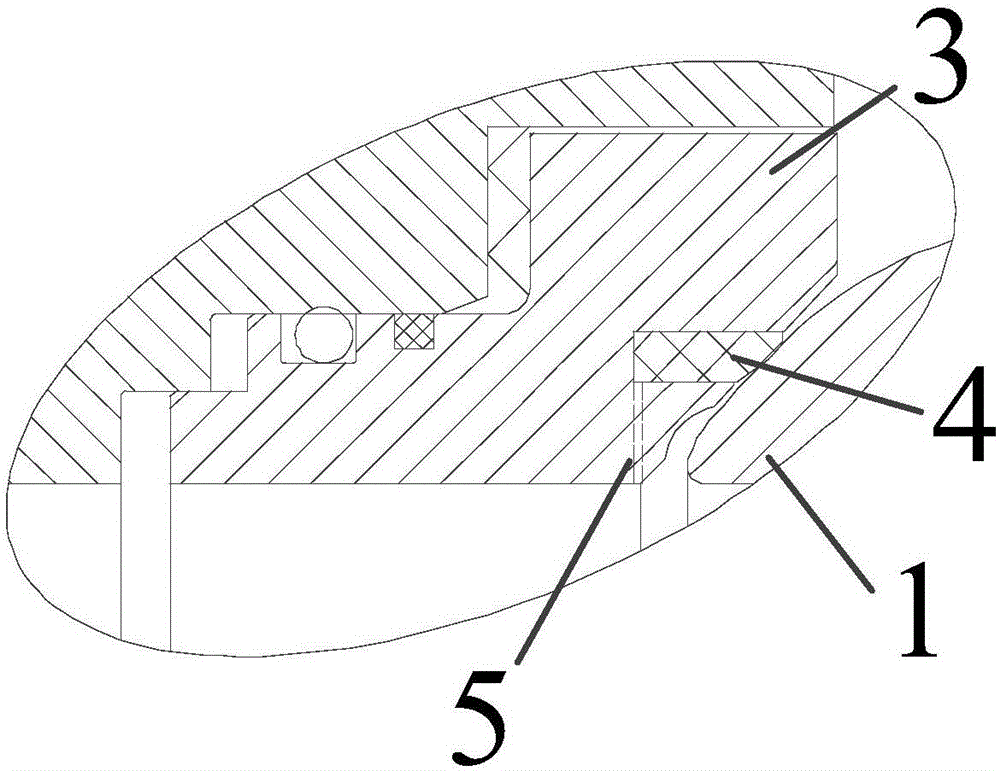

[0055] like figure 2 As shown, the sealing ring 4 is set in the vertical direction between the retainer 3 and the valve core 1, and is snapped into the annular groove of the inner cavity of the retainer 3; the sealing ring 4 faces the valve spool 1 is biased and sealingly engaged with said spool 1;

[0056] The sealing ring 4 is in interference fit with the annular groove, and an exhaust groove is provided between the inner ring and the annular groove for discharging the air in the annular groove during the installation of the sealing ring 4 .

[0057] The above-mentioned sealing ring is arranged in the annular groove of the inner cavity of ...

Embodiment 2

[0077] like figure 1 As shown, the sealing valve includes: a valve core 1, a valve body 2, and a retainer 3 arranged between the valve core 1 and the valve body 2, the above-mentioned valve core 1 is a spherical valve core; the sealing structure includes:

[0078] like figure 2 As shown, the sealing ring 4 is set in the vertical direction between the retainer 3 and the valve core 1, and is snapped into the annular groove of the inner cavity of the retainer 3; the sealing ring 4 faces the valve spool 1 is biased and sealingly engaged with said spool 1;

[0079] The sealing ring 4 is in interference fit with the annular groove, and an exhaust groove is provided between the inner ring and the annular groove for discharging the air in the annular groove during the installation of the sealing ring 4 .

[0080] The above-mentioned sealing ring is arranged in the annular groove of the inner cavity of the retainer, and is biased and sealed toward the spherical valve core, so that ...

Embodiment 3

[0100] like figure 1 As shown, the sealing valve includes: a valve core 1, a valve body 2, and a retainer 3 arranged between the valve core 1 and the valve body 2, the above-mentioned valve core 1 is a spherical valve core; the sealing structure includes:

[0101] like figure 2 As shown, the sealing ring 4 is set in the vertical direction between the retainer 3 and the valve core 1, and is snapped into the annular groove of the inner cavity of the retainer 3; the sealing ring 4 faces the valve spool 1 is biased and sealingly engaged with said spool 1;

[0102] The sealing ring 4 is in interference fit with the annular groove, and an exhaust groove is provided between the inner ring and the annular groove for discharging the air in the annular groove during the installation of the sealing ring 4 .

[0103] The above-mentioned sealing ring is arranged in the annular groove of the inner cavity of the retainer, and is biased and sealed toward the spherical valve core, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com