Anti-permeation equipment for gas thermometer

An anti-penetration, thermometer technology, applied in the field of gas thermometers, can solve the problem of not being able to perform one-time inspection and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below by specific embodiment:

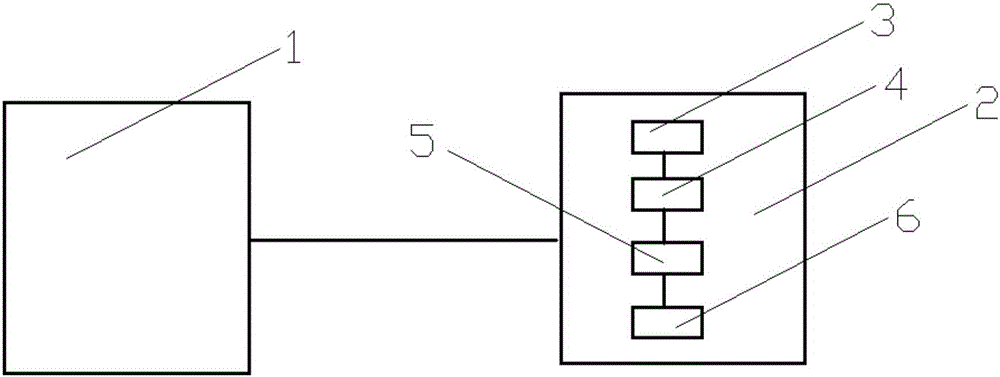

[0011] Such as figure 1 As shown, the anti-penetration equipment of the gas thermometer includes the anti-penetration component 1, the base frame 2, the riveting component 3 and the splicer 4. Device 5 and reaction impact buffering part 6. The control and detection component 5 of the anti-infiltration equipment of the gas thermometer uses the inspection piston 7 and the rod-shaped pin 8 to inspect the infiltration density through the gas flow drawn out from the inner pipeline. The inspection piston 7 is a serial multi-stage electromagnetic switch inspection piston.

[0012] The working principle of the present invention is to use the adaptive electronic inspection sealer 5 and the reaction impulse buffering part 6 through the anti-penetration device of the gas thermometer. The control and detection component 5 of the anti-infiltration equipment of the gas thermometer uses the inspection p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com