Annular damping parts dynamic characteristic test vibration table device

A technology for testing vibration and dynamic characteristics, which is applied in the mechanical field, can solve the problems of poor versatility of the test device, affect the accuracy of test results, and the test axis cannot guarantee the same vibration direction in the test direction of the sensor, so as to achieve accurate positioning, good compression effect, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

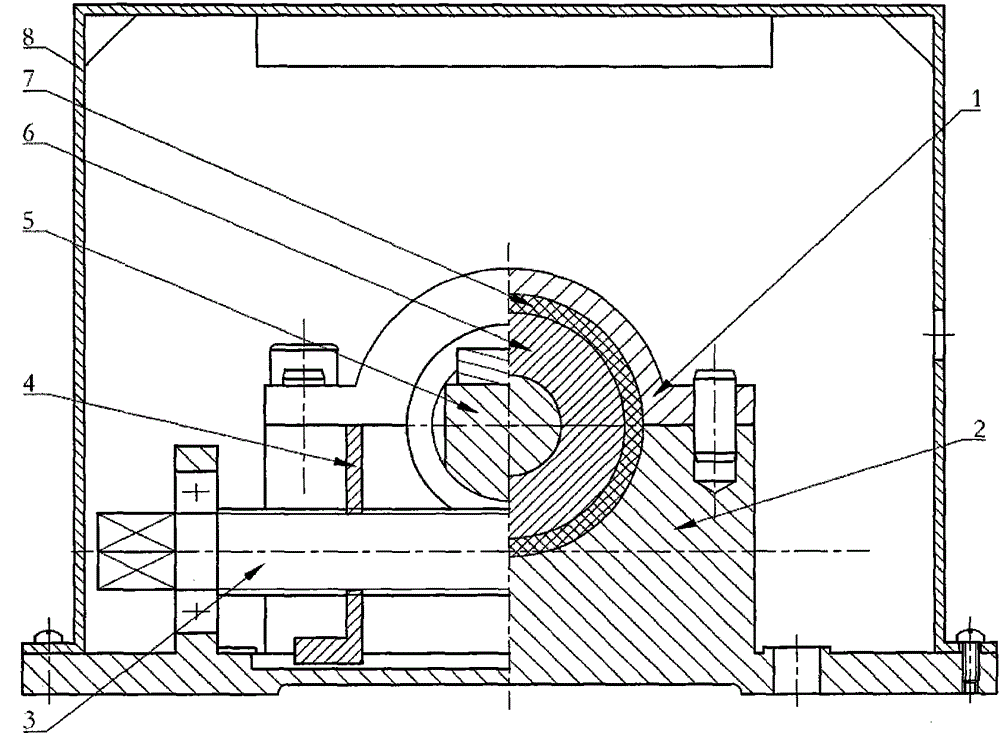

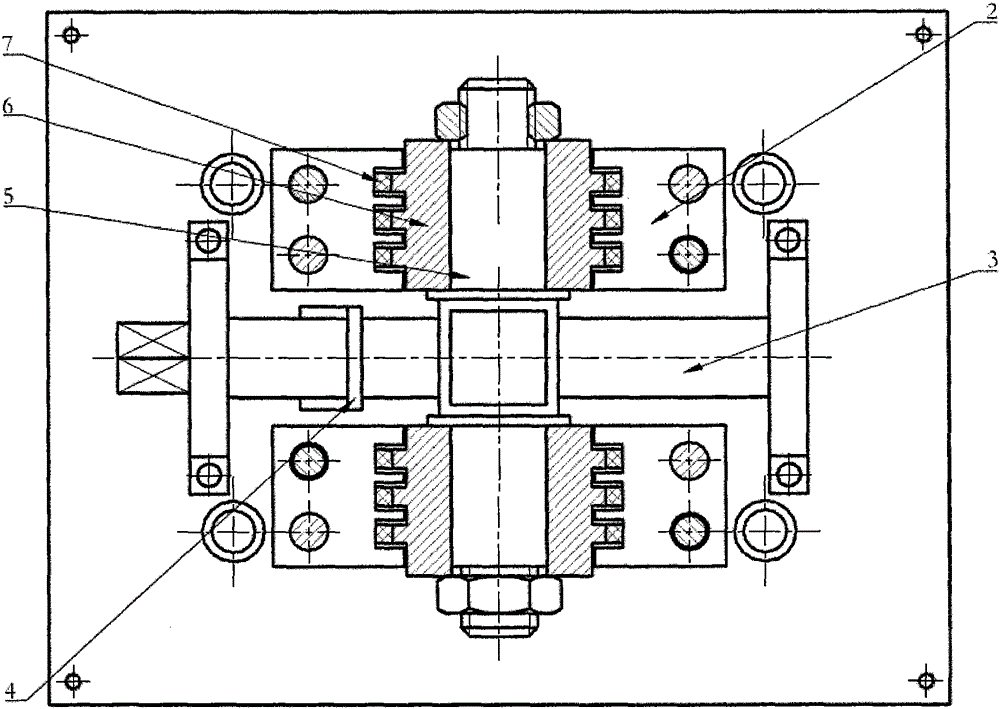

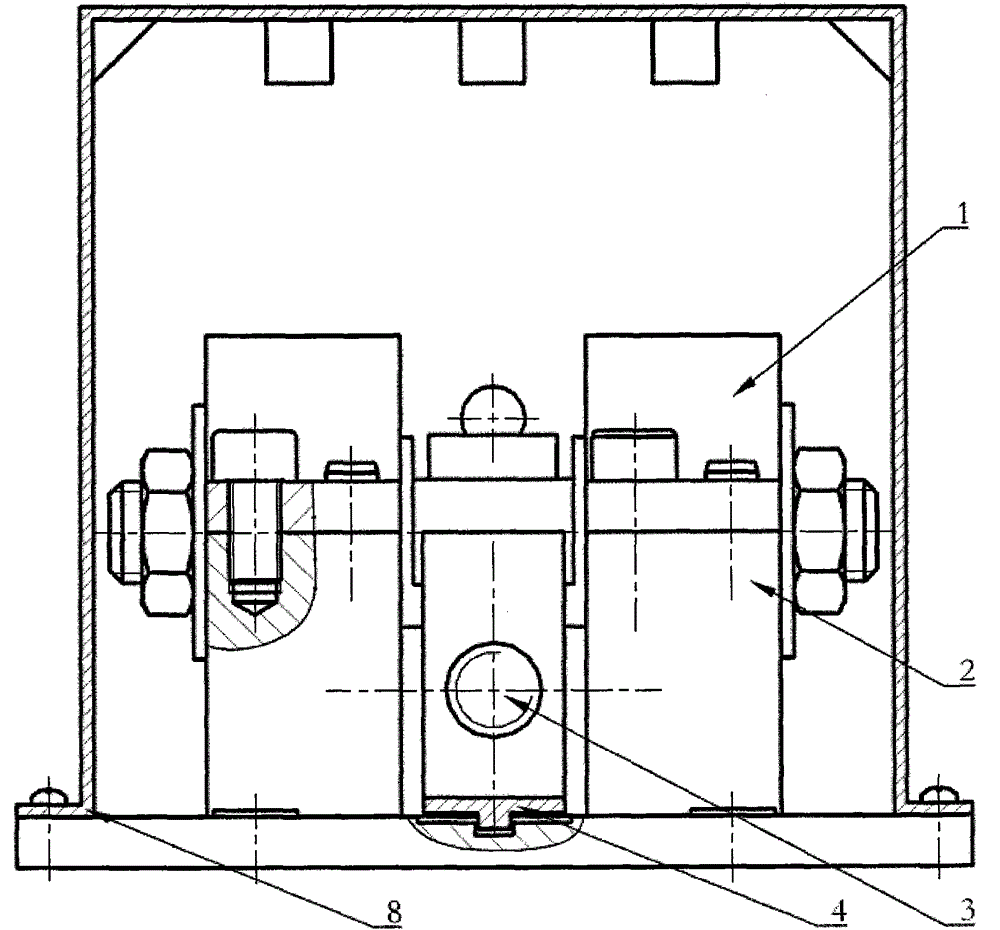

[0039] The structure and working process of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0040] Such as figure 1 , figure 2 and image 3 As shown, a vibrating table device for testing the dynamic characteristics of annular damping parts of the present invention includes a vibrating table, an upper base 1, a lower base 2, a test calibration rod 3, a test calibration block 4, a test shaft 5, a shaft sleeve 6 and a thermal insulation Cover 8. The vibrating table adopts the existing one.

[0041] Such as Pic 4-1 , Figure 4-2 , Figure 4-3 As shown, the upper base 1 in the present invention is a semi-circular structure with flanges on both sides, the center of the upper base 1 is a concave semi-cylindrical surface, and the concave semi-cylindrical surface of the upper base 1 is processed with Multi-track annular positioning groove I9, the groove depth of multi-track annular positioning groove I9 is the same, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com