A test system for material rotational impact response characteristics

A technology of impact response and characteristic testing, which is applied in the direction of testing material strength, analyzing materials, and strength characteristics by using one-time impact force, and can solve problems such as inability to implement rotational pulse loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0031] The system is installed on the horizontal rigid test platform in the laboratory to test the rotation-shock response characteristic parameters of the material.

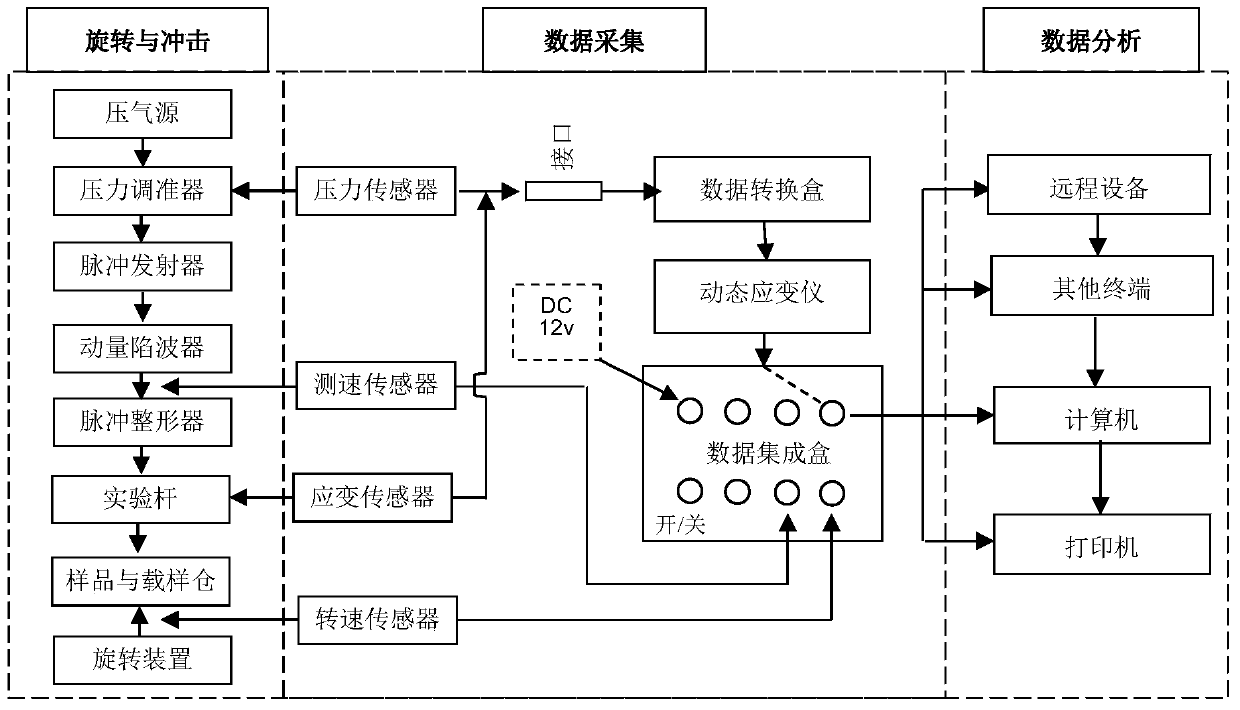

[0032] Such as Figure 1-6 Shown is a schematic structural diagram of the test system for the rotational impact response characteristics of materials of the present invention, the system includes (i) a rotational and impact unit, (ii) a data acquisition unit and (iii) a data analysis unit,

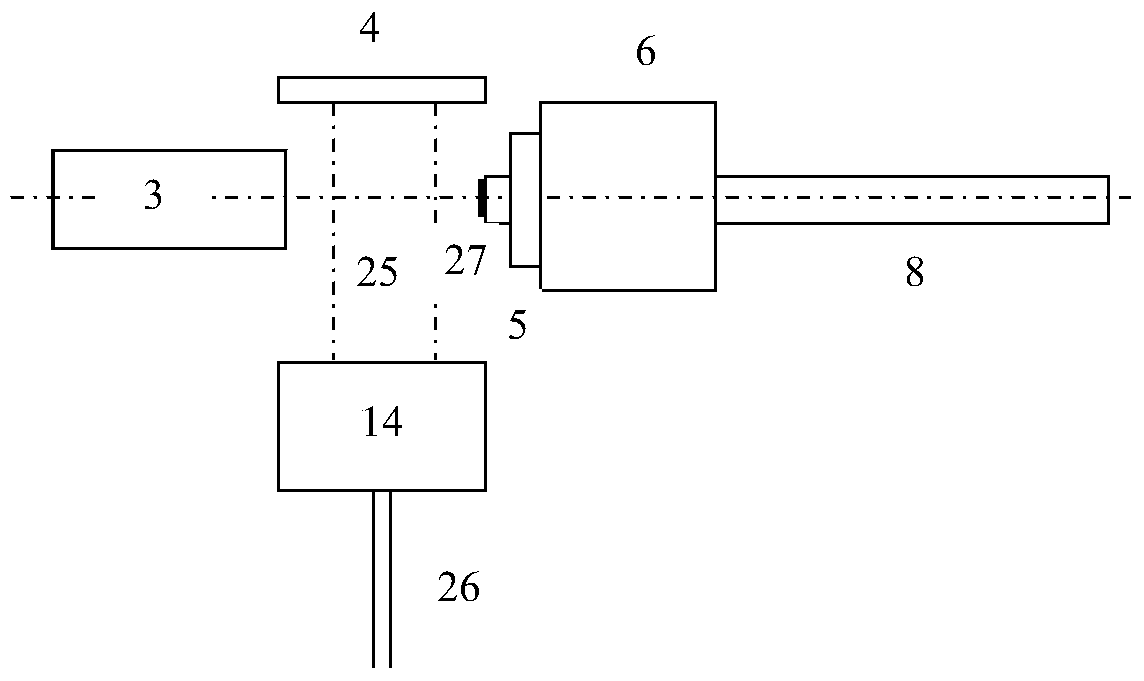

[0033] The rotation and impact unit is composed of a system platform, a pulse generating unit, a sample loading chamber and a rotation unit;

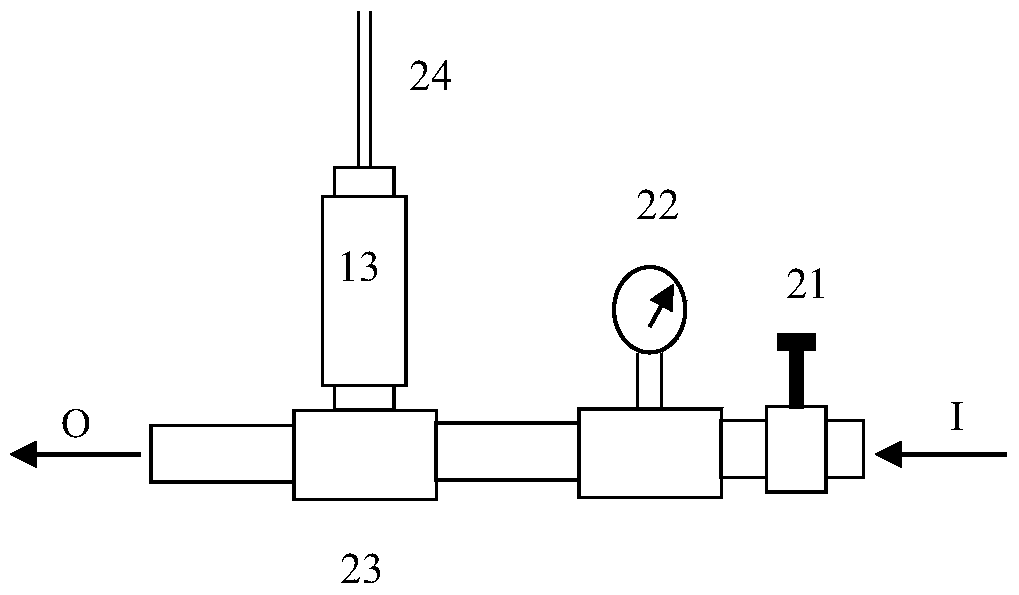

[0034] The pulse generating unit is composed of a pressure source, a pressure regulator, a pulse transmitter, a pulse shaper, a conversion valve, a momentum trap and an experimental rod;

[0035] The sample loading chamber is used to carry samples;

[0036] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com