Touch sensitive equipment for mobile phone

A touch-sensitive device, mobile phone technology, applied in branch equipment, data processing input/output process, telephone communication and other directions, can solve the problems of separation of TP front shell, difficult disassembly of TP, troublesome maintenance, etc., and achieve ultra-narrow touch screen black border , The effect of reducing maintenance costs and reasonable layout planning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

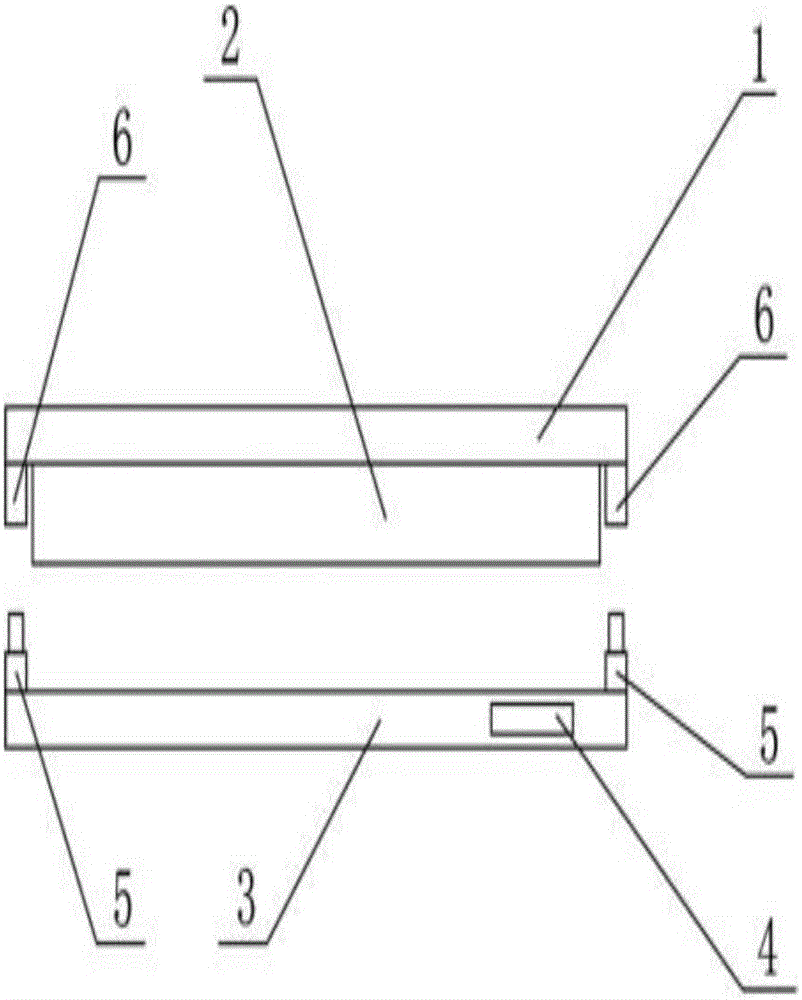

[0022] A touch-sensitive device for a mobile phone, comprising a touch screen outer panel 1, an FPC sensing circuit board 2 and a mobile phone main board 3 stacked sequentially from top to bottom, the FPC sensing circuit board 2 is electrically connected to the mobile phone main board 3, the The mobile phone main board 3 is provided with a touch screen chip 4 electrically connected to the FPC sensing circuit board 2, and the FPC sensing circuit board 2 and the mobile phone main board 3 are mutually movable and clamped;

[0023] The touch screen outer panel 1 includes a top ITO board and OCA optical glue. The top ITO board is the cover of the touch-sensitive device, the contact surface touched by the user, and also the upper circuit part of the touch screen. It is printed by silver paste and ITO Etching combined wiring, the OCA optical glue is used to bond the top ITO board and FPC sensing circuit board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com