Split-type anti-misoperation device for substation secondary equipment and the protection method realized by using the device

An anti-misoperation device and secondary equipment technology, which is applied in the direction of guards/shutters to prevent contact with contacts, can solve the problems of affecting power supply reliability, time-consuming and labor-intensive work, and insufficient firmness, so as to improve service life and ease of use. Operability, ease of use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

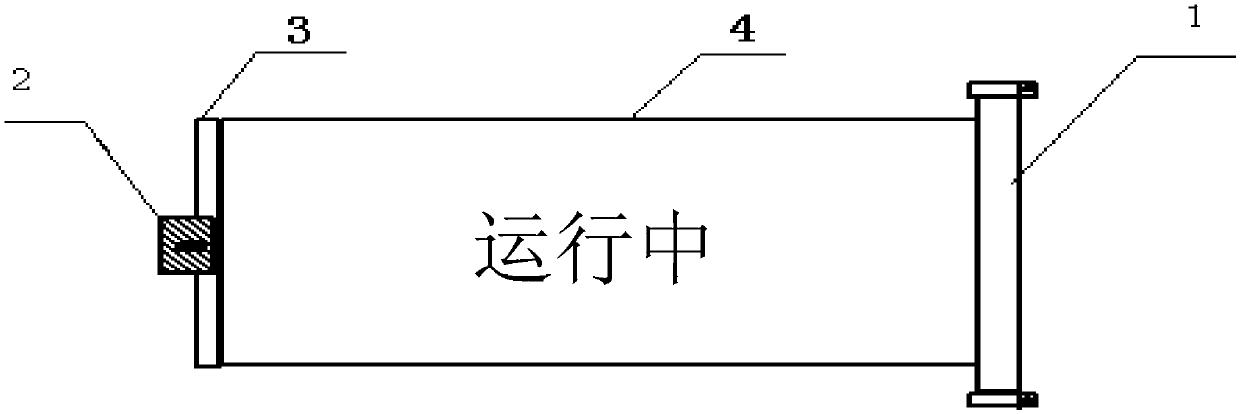

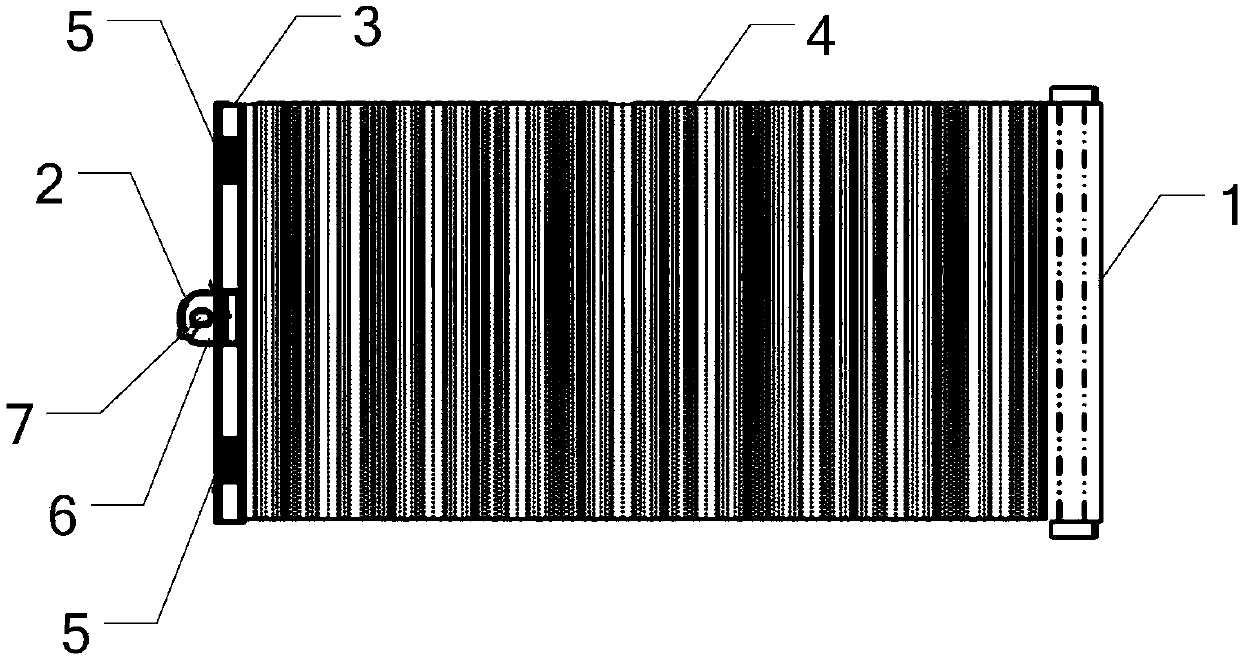

[0031] Specific implementation mode one: refer to figure 1 and 2 Describe this embodiment in detail. The substation secondary equipment split type anti-misoperation device described in this embodiment includes a telescopic device 1, an anti-misoperation lock 2, a traction pressure plate 3, a barrier 4 and a soft magnet 5.

[0032] There is a strip-shaped gap on the side wall of the expansion device 1, and one end of the barrier 4 is fixedly wound on the expansion device 1 through the strip-shaped gap, and the expansion device 1 is used to control the expansion and contraction of the barrier 4.

[0033] The other end of blocking 4 is fixedly pasted on the traction pressure plate 3, and the middle part of traction pressure plate 3 is provided with outward semicircular protrusion 6, and is provided with lock hole 7 on this protrusion 6, and this lock hole 7 is used for inserting anti In mis-lock 2, use anti-mislock 2 to lock,

[0034] The upper and lower ends of the traction pr...

specific Embodiment approach 2

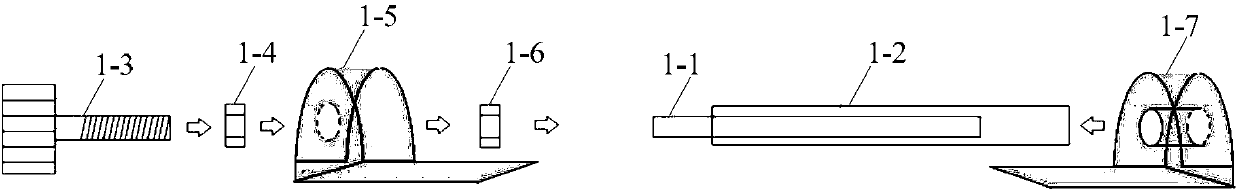

[0036] Specific implementation mode two: refer to image 3 Describe this embodiment in detail. This embodiment is a further description of the substation secondary equipment split-type anti-misoperation device described in Embodiment 1. In this embodiment, the telescopic device 1 includes a nylon rod 1-1, a rotating sleeve 1-2, rotating handle 1-3, fixing nut 1-4, mounting base 1-5, limit nut 1-6 and fixing base 1-7,

[0037] The nylon rod 1-1 is inserted from one end of the rotating sleeve 1-2, and the inside of the nylon rod 1-1 is hollow and has internal threads, and the rotating handle 1-3 with external threads is screwed into the fixing nut 1-4 Finally, pass through the mounting base 1-5 and the limit nut 1-6 in turn and screw into the inner thread of the nylon rod 1-1,

[0038] The other end of the rotating sleeve 1-2 is connected with the fixed seat 1-7,

[0039] The side walls of the mounting base 1-5 and the fixing base 1-7 are jointly provided with strip-shaped sli...

specific Embodiment approach 3

[0042] Specific implementation mode three: refer to Figure 4 and 5 Describe this embodiment in detail. This embodiment is a further description of the substation secondary equipment split type anti-misoperation device described in the first embodiment. In this embodiment, the anti-misoperation lock 2 includes a latch 2-1 and a lock slot 2. -2, lock body 2-3, locking groove 2-4, locking block 2-5 and fixed piece 2-6,

[0043] There is a lock groove 2-2 inside the lock body 2-3, and the latch 2-1 is screwed to one side of the lock body 2-3 through the fixed piece 2-6 and inserted into the lock groove 2-2. The lock block 2-5 Fixedly connected with the latch 2-1 in the lock groove 2-2,

[0044] The lock hole 7 is inserted into the lock groove 2-2, and the latch 2-1 drives the lock block 2-5 to pass through the lock hole 7 and enter the lock groove 2-4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com