Rotary regulation mechanism of hydraulic lifting seat

A rotary adjustment, hydraulic lifting technology, applied in vehicle seats, movable seats, special positions of vehicles, etc., can solve the problems of reduced effective use area, no locking mechanism for lift seats, and narrow use space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

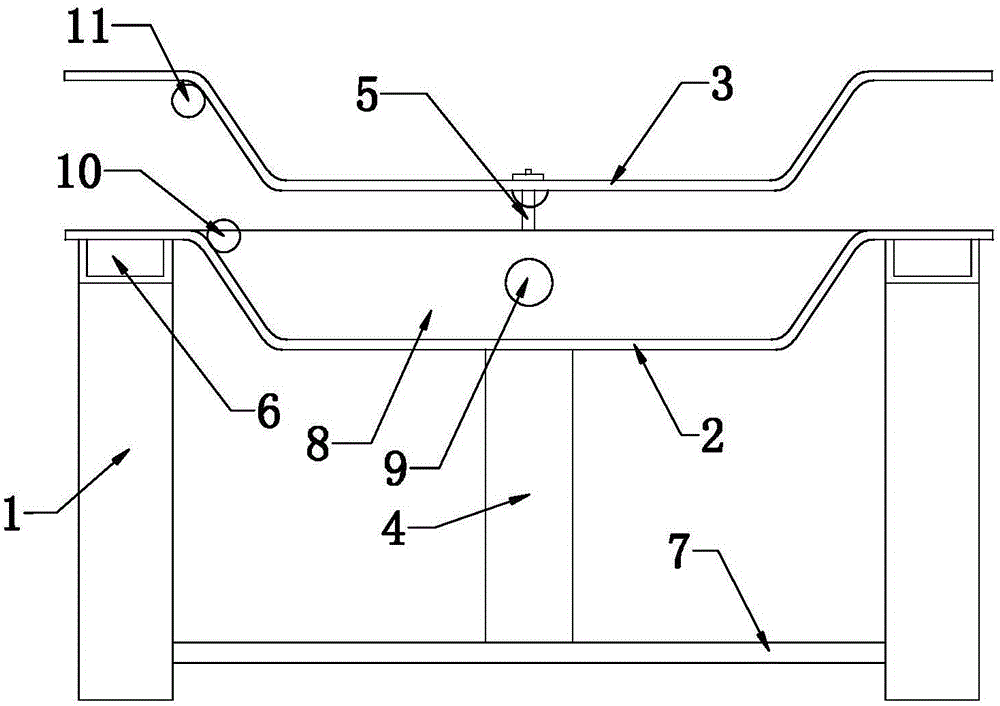

[0014] The rotary adjustment mechanism of the hydraulic lifting seat of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0015] As shown in the figure, the hydraulic lift seat rotation adjustment mechanism of the present invention includes a seat frame 1, a mounting base 2 arranged on the seat frame 1 and a seat base 3 located above the mounting base, and the bottom of the mounting base 2 is arranged There is a cylinder block 4 between the seat brackets, said cylinder block 4 is an air cylinder block or a hydraulic cylinder block, preferably a hydraulic cylinder, and the telescopic rod 5 in the cylinder block 4 stretches out from the top of the mounting base 2 and is connected to the seat The bottom of the chair base, the seat base 2 can rotate around the center of the telescopic rod after the telescopic rod stretches out.

[0016] It can be seen from the figure that the seat frame include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com