Heat shrinkable cable accessory and preparation method thereof

A technology of cable accessories and heat shrinkage, which is applied in the direction of cable accessories, electrical components, cable joints, etc., which can solve problems such as insufficient holding force, anti-pollution flashover, weak anti-creepage performance, and power line distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

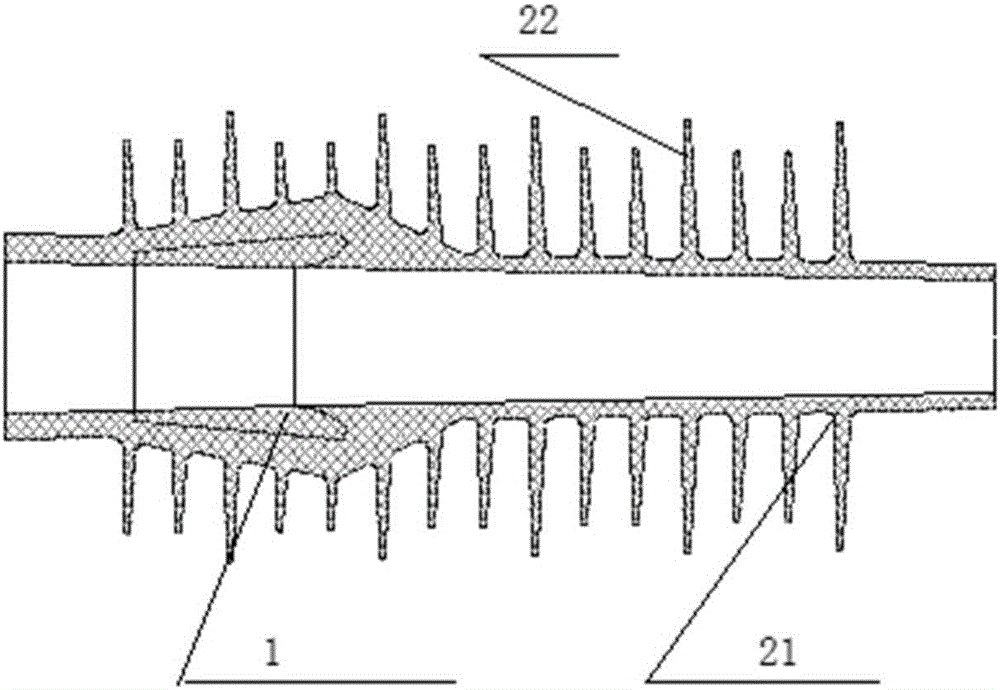

[0032] Such as figure 1 As shown, a heat-shrinkable cable accessory in the embodiment of the present invention includes:

[0033] The stress cone 1 and the heat-shrinkable shed assembly; the stress cone 1 and the heat-shrinkable shed assembly are injection-molded into one structure; or, the stress cone is sleeved on the part to be protected of the power distribution transmission line, The heat-shrinkable shed assembly is sleeved on the stress cone.

[0034] Wherein, the heat-shrinkable shed assembly includes a heat-shrinkable insulating tube 21 and a shed 22 . Stress cone 1 can choose conductive stress cone.

[0035] That is to say, the heat-shrinkable shed assembly includes a heat-shrinkable insulating tube and a shed arranged on the heat-shrinkable insulating tube.

[0036] In the embodiment of the present invention, the accessories can effectively control the partial discharge and ensure the safe operation of the wires and accessories; at the same time, the design of the...

Embodiment 2

[0045] A method for preparing a heat-shrinkable cable accessory in an embodiment of the present invention includes:

[0046] Step 1, preparing a stress cone;

[0047] Step 2, placing the prepared stress cone into the preset forming mold of the heat-shrinkable shed assembly;

[0048] Step 3, and then form a heat-shrinkable cable accessory with an integrated structure of the stress cone and the heat-shrinkable shed assembly by injection molding through the molding die.

[0049] The method in the embodiment of the present invention is designed by injecting the modified stress cone, the shed, and the insulating tube into one body. It has long creepage distance, relatively short cable accessories, and is easy to install. The heat-shrinkable cable accessories have high strength and good sealing performance. features.

[0050] The heat-shrinkable cable accessories prepared by the method in the embodiment of the present invention control the electric field stress through the heat-sh...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap