Matching method of special bearing for inertial navigation platform

A bearing and platform technology, which is applied in the direction of three-dimensional position/channel control, etc., can solve the problems that the starting friction torque does not meet the index requirements, the preload error of the paired bearing is large, and the pairing bearing is low, so as to meet the requirements of smooth starting friction torque, The effect of low starting friction torque requirement and high rotation accuracy

Inactive Publication Date: 2010-06-23

LUOYANG BEARING SCI & TECH CO LTD

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the level of matching bearings developed in China is low, and the precision is not high, and the inertial navigation platform assembled cannot achieve high precision and good performance

The existing paired bearing selection method uses instruments to test the end surface protrusion value of a single set of bearings under a certain preload, and then grinds or repairs the end surface protrusion amount, which completes the preload matching of the bearings. , such a pairing can be applied to frame supports with low performance requirements, but there are two insurmountable problems for inertial navigation platform frame systems with high performance requirements

One is that the error of the pretightening force of the matching bearing is large, and sometimes the error value can reach about 50% of the design value, which is mainly due to the measurement of the protrusion amount being affected by various factors such as the error of the instrument system, the accuracy of the test accessories, and the accuracy of the bearing product The impact of the paired bearing pretightening force is also affected by the bearing rotation accuracy and part accuracy, and these factors are random and combined, it is difficult to accurately capture and eliminate

The second is that the starting friction torque of the paired bearings does not meet the index requirements and the fluctuation value is large. This is because the accuracy of the single set of bearings in the paired bearings is low, and the consistency of some key dimensional accuracy and shape accuracy in the two sets of bearings is poor. Caused, and there are many factors that affect the starting friction torque of the bearing and are very complicated, it is difficult to completely rule out

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

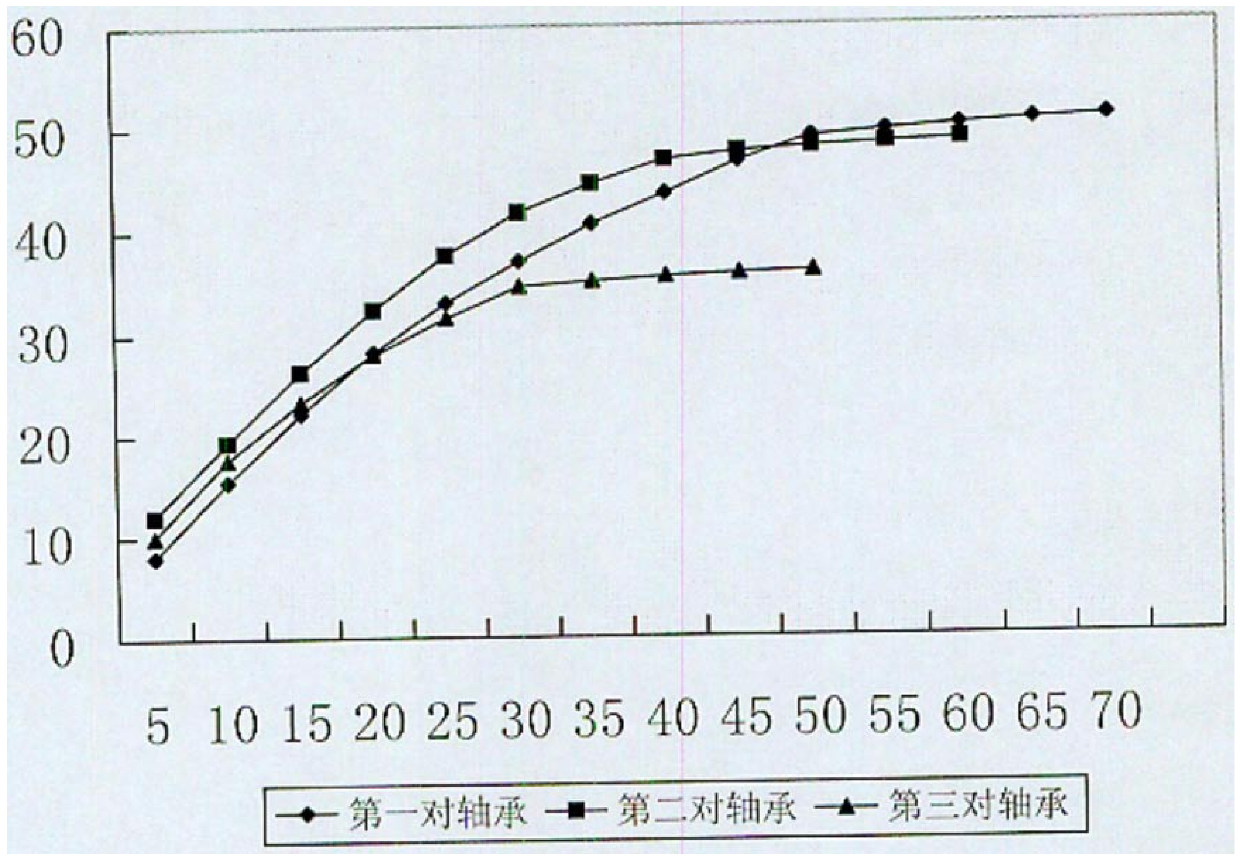

The invention belongs to the technical field of precision rolling bearings, and relates to a matching method for special bearings for inertial navigation platforms. The matching steps are: (1) preselection, (2) pairing, (3) measuring and correcting the protrusion of the end face of the single set of bearings, (4) measuring and correcting the deformation of the inner ring of the paired bearing, (5) testing the paired bearing starting friction torque. The method of the invention can reduce the error of the pre-tightening force of the paired bearings, make the starting friction torque of the bearings meet the requirements, and greatly improve the performance of the inertial navigation platform.

Description

Matching method of special bearing for inertial navigation platform technical field The invention belongs to the technical field of precision rolling bearings, and relates to a matching method for special bearings for inertial navigation platforms. Background technique The inertial navigation platform is an important device to establish a stable three-axis coordinate system for the aircraft to control the flight trajectory and attitude of the aircraft. The platform frame support bearing used in it is the main guarantee for the accuracy, reliability and life of the inertial navigation platform. . The structural forms of support bearings include deep groove ball bearings, angular contact ball bearings, double row angular contact ball bearings, etc., and the paired angular contact ball bearings are most used in inertial navigation platforms. In order to realize the technical requirements of inertial navigation platform for bearings, a lot of research has been done on inertia...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G05D1/10

Inventor 蒋蔚梁波焦育洁马美玲王瑞生张锡昌王子君张健

Owner LUOYANG BEARING SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com