Swing rod screening machine

A screening machine and rack technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of unsafe operators, difficult human operation, unsuitable machines, etc., and achieve the effect of eliminating potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

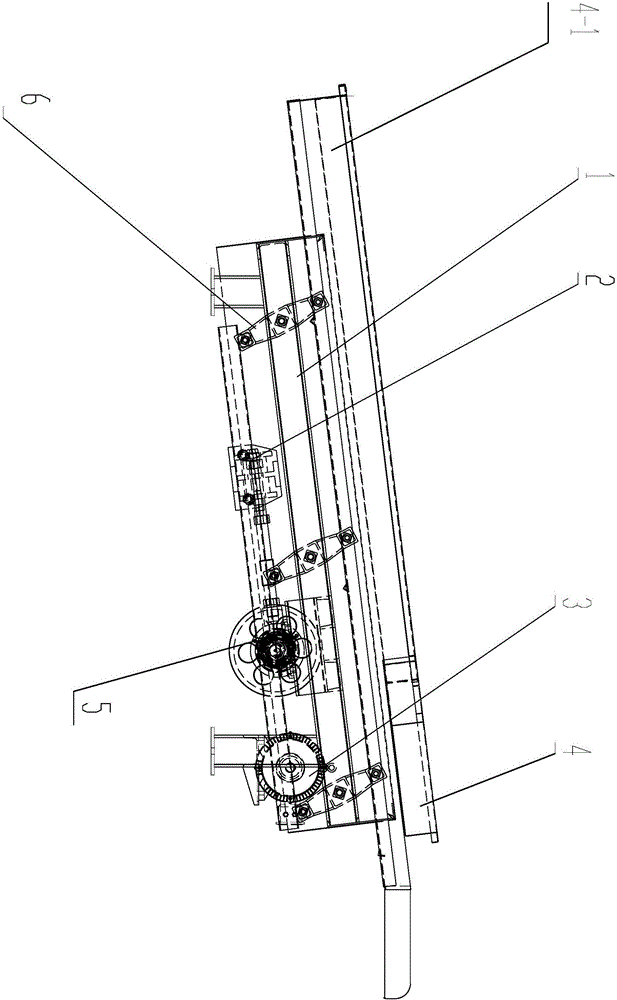

[0013] Embodiment 1: as figure 1 , figure 2 As shown, the pendulum screening machine includes frame 1, motor 3, pulley 5, trough 4, balance frame part 2, and short rocker arm 6. The motor and pulley are set on the right side of the trough, that is, the side with the highest trough. In the space below, the height of the motor is generally 200mm, and the height of the pulley is generally 300mm. After adjustment, the height of the machine can be saved by about 100mm, which greatly improves the configuration space of some production processes and adjacent equipment. The lower side of the trough moves back to the lower end. The length of the part 4-1 is 200mm. Because the trough is inclined, the lower it moves back, the lower end can be adjusted at will according to the height of the inlet and outlet of the equipment next to it. , which greatly facilitates the layout of the production line.

Embodiment 2

[0014] Embodiment 2: The trough of the pendulum screening machine is a screen, and the screen is replaced with a corrugated plate to become a pendulum conveyor, which improves the conveying function. The maximum conveying angle of the swing bar screening machine is 7°, while the conveying angle of the swing bar conveyor can be 13°. Therefore, when the height difference of material conveying is constant, the length of the pendulum conveyor can be shortened by nearly half.

Embodiment 3

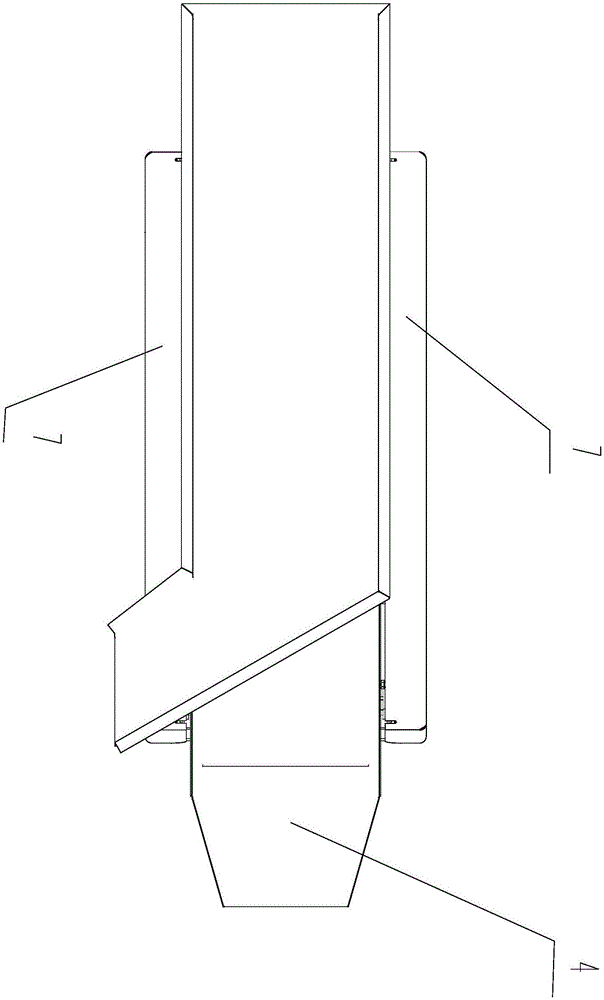

[0015] Embodiment 3: as figure 2 As shown, the rocker arm 6 is changed from the original outer side to be fixed on the inner side of the frame 1. When the operator is close to the machine, the frame will block it and will not directly touch the swinging rocker arm, which increases safety. A protective cover 7 can also be provided outside the frame at the corresponding position of the rocker arm, which not only further eliminates potential safety hazards during the operation of the rocker arm, but also increases the appearance of the machine.

[0016] In the present invention, the motor and the belt pulley are arranged on the right side of the trough, that is, the side where the trough is high, which saves the height of the original motor and the belt pulley, and utilizes the space under the high side of the frame. The lower side of the trough is moved back to the lower end, which is convenient for matching with the machine next to it during material transportation, and the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com