UHP tire for promoting high speed and durability

A high-speed durability, tire technology, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve problems such as performance can not keep up, and achieve the effect of reducing deformation, improving rigidity, and reducing energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

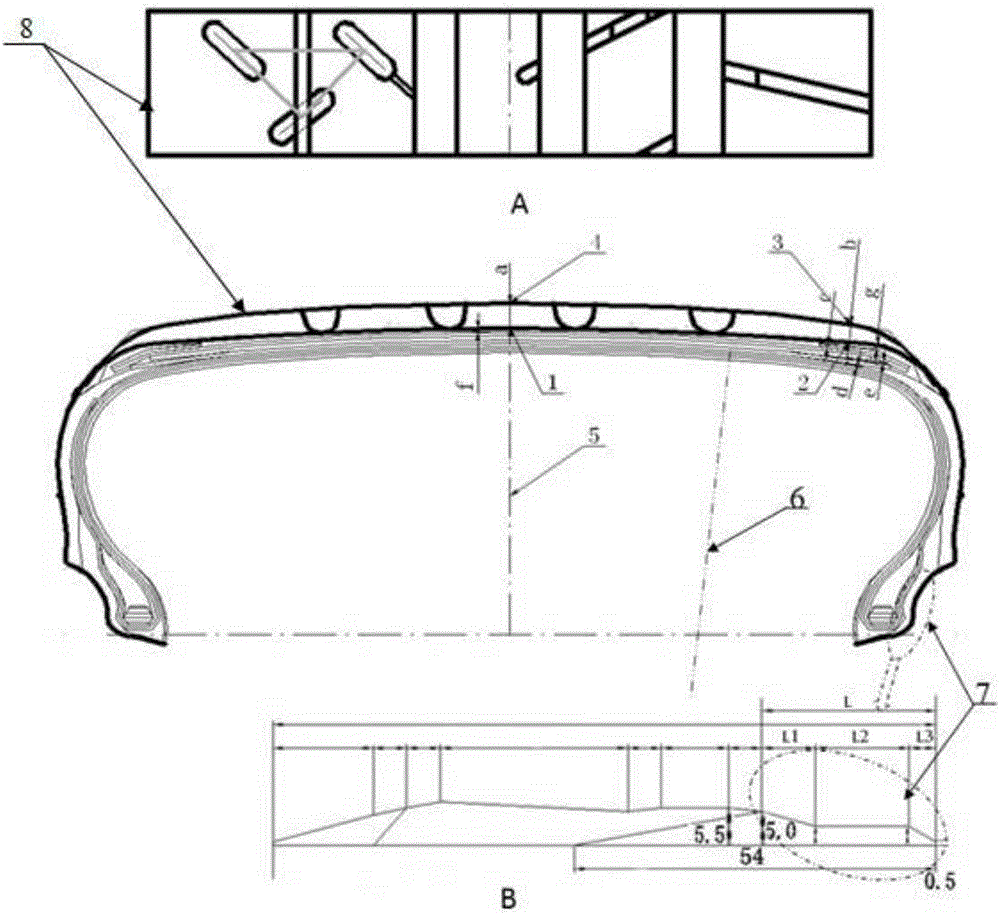

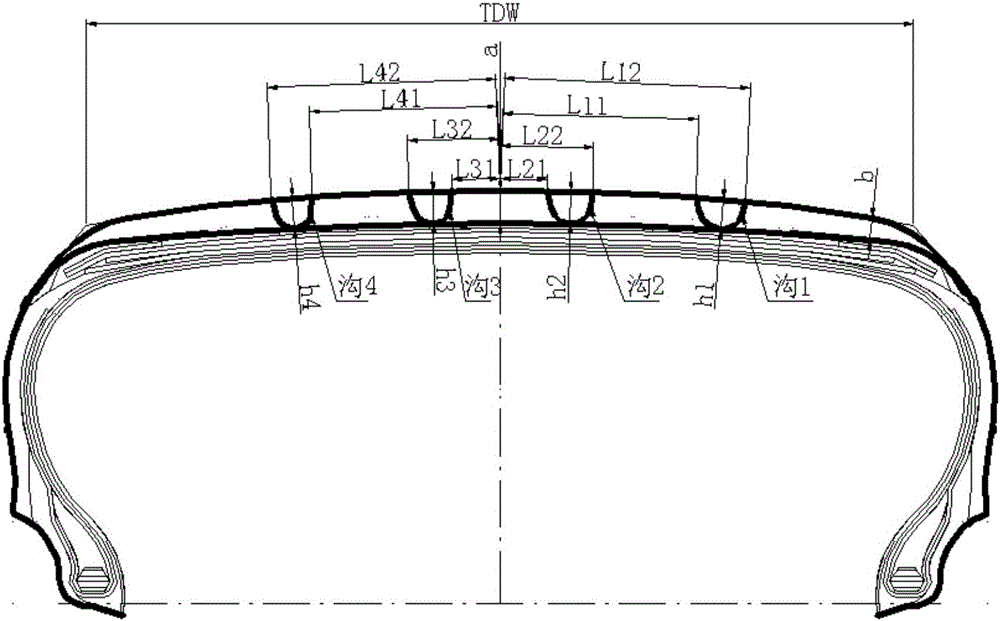

[0043] According to one embodiment of the present invention, as attached figure 1 As shown, a UHP tire for improving high-speed durability includes a tread 8 and a sidewall 7. The tread 8 is provided with a first main groove, a second main groove, a third main groove, and a second main groove in sequence from the inner side. Four main grooves and tread outer pattern, the sidewall 7 includes waterproof line, slit and sidewall end in turn; the tread outer pattern is composed of several groups of self-fixing patterns, and the self-fixing patterns are three depressions on the tire The pattern transverse grooves on the surface, wherein each group of self-fixing patterns includes two pattern transverse grooves 1 and 2 on the tread surface located on both sides of the fourth main groove, and one located on the fourth main groove and The pattern transverse grooves on the two sides of the tread are three; the center points of the three pattern transverse grooves of each group of self-...

Embodiment 2

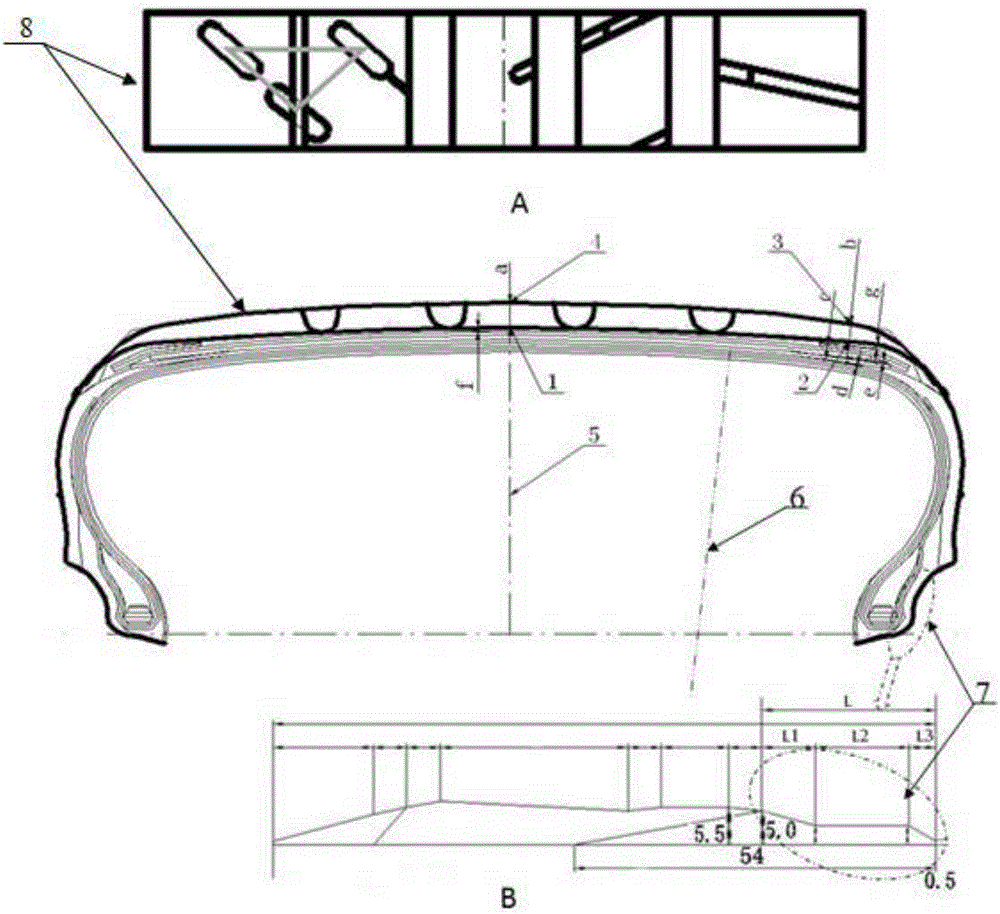

[0050] According to one embodiment of the present invention, as attached figure 2 As shown, a UHP tire for improving high-speed durability includes a tread 8 and a sidewall 7. The tread 8 is provided with a first main groove, a second main groove, a third main groove, and a second main groove in sequence from the inner side. Four main grooves and tread outer pattern, the sidewall 7 includes waterproof line, slit and sidewall end in turn; the tread outer pattern is composed of several groups of self-fixing patterns, and the self-fixing patterns are three depressions on the tire The pattern transverse grooves on the surface, wherein each group of self-fixing patterns includes two pattern transverse grooves 1 and 2 on the tread surface located on both sides of the fourth main groove, and one located on the fourth main groove and The pattern transverse grooves on the two sides of the tread are three; the center points of the three pattern transverse grooves of each group of self-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com