Unloading structure of polyester silk raw material powder

A raw material powder and polyester filament technology, applied in loading/unloading, conveying bulk materials, conveyors, etc., can solve the problems that powder raw materials are easy to stick to the inner wall of the unloading pipe, time-consuming and laborious, and inconvenient unloading operation, etc., to ensure The effect of unloading speed, convenient unloading operation and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

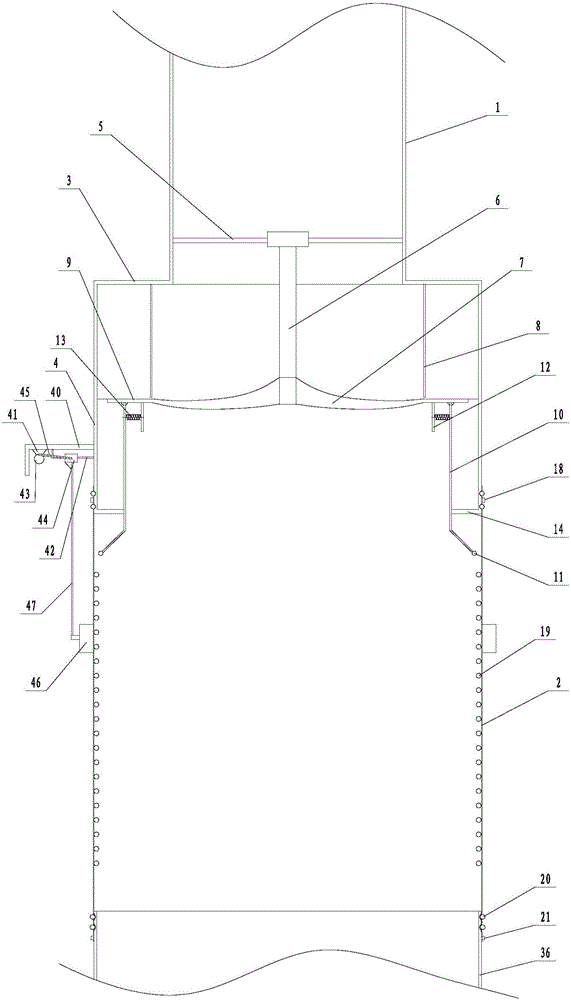

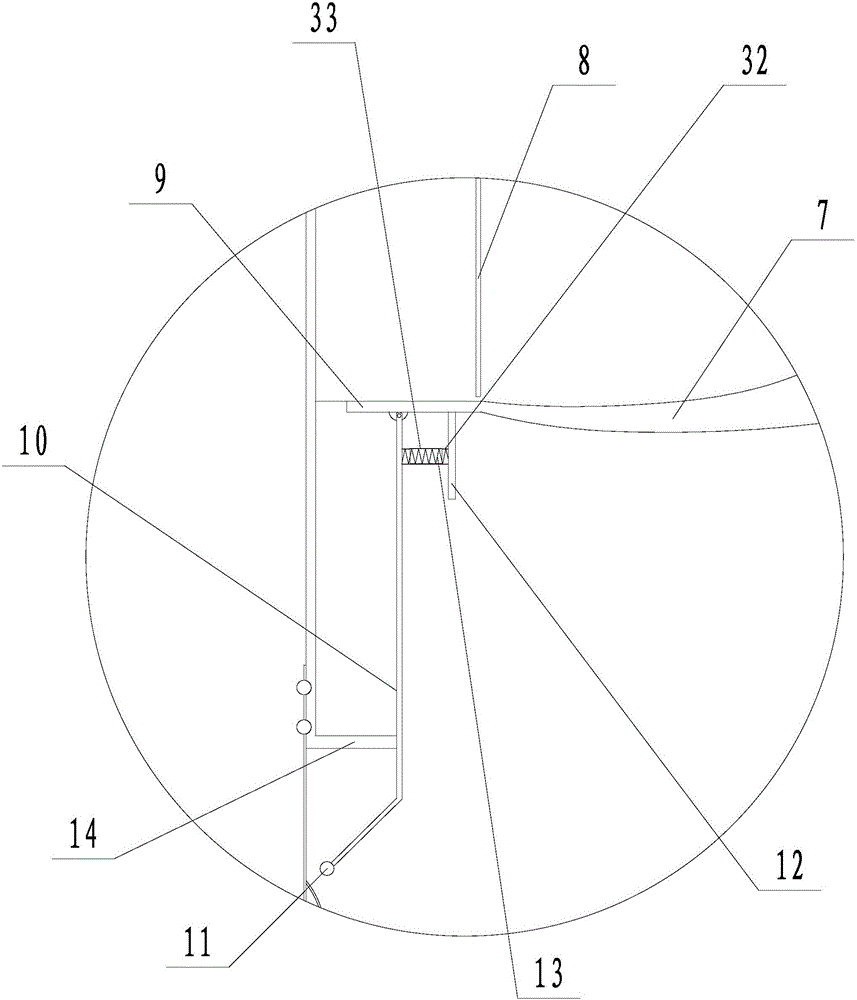

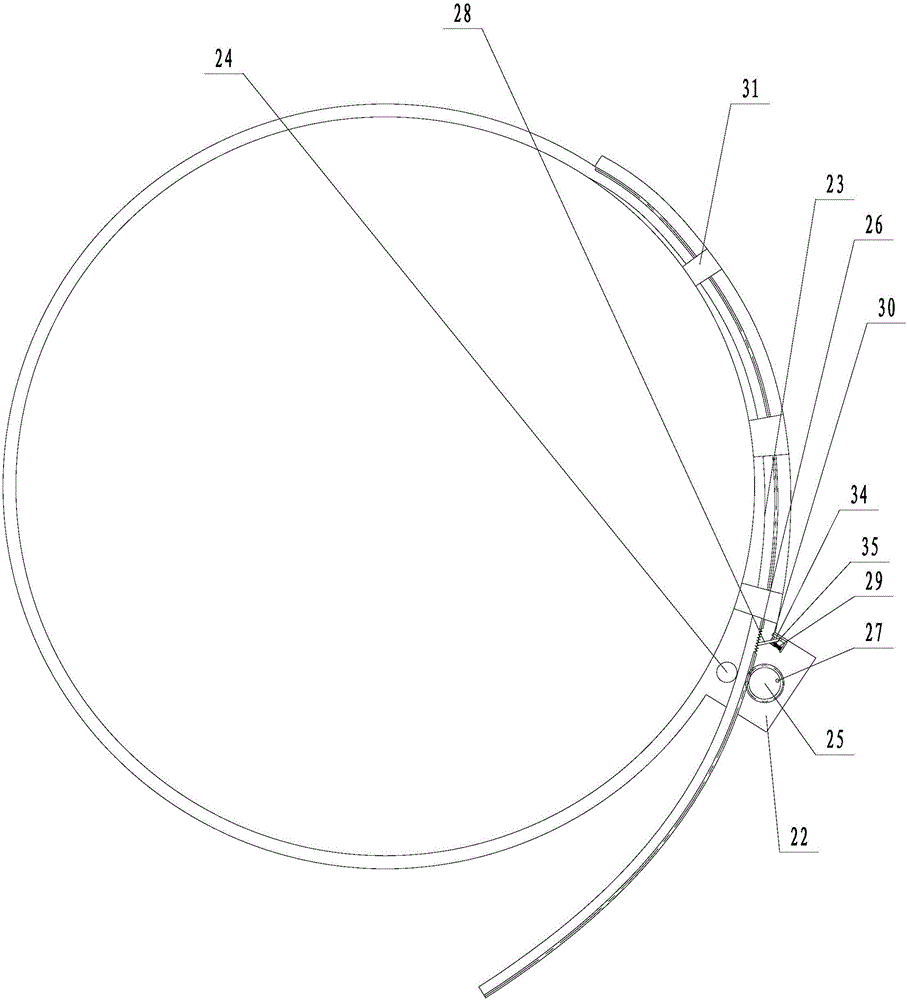

[0020] Embodiment: a kind of unloading structure of polyester yarn raw material powder (see attached Figures 1 to 7), including discharge pipe 1, cloth bag pipe 2, the lower end of the discharge pipe is provided with a connecting pipe 4, the inner diameter of the connecting pipe is larger than the inner diameter of the discharge pipe, and a transition ring 3 is connected horizontally between the connection pipe and the discharge pipe, and the discharge pipe A discharge valve is installed on the top, the side wall of the bag pipe is sealed, and a waterproof layer is provided on the outer surface of the bag pipe. The upper end of the bag pipe is tightly sleeved on the outer wall of the lower end of the connecting pipe, and a locking ring 18 is sleeved on the outer wall of the upper end of the bag pipe. One end of the locking ring is connected with a locking pin 37, and the other end of the locking ring is equidistantly provided with several locking rings. Hole 38, locking pin i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com