Multi-dimensional adjusting mechanism for vertical rod

A multi-dimensional adjustment and pole technology, applied in the direction of lifting device, lifting frame, etc., can solve the problems of low precision, poor flexibility, difficult to popularize, etc., and achieve the effect of flexible and quick operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

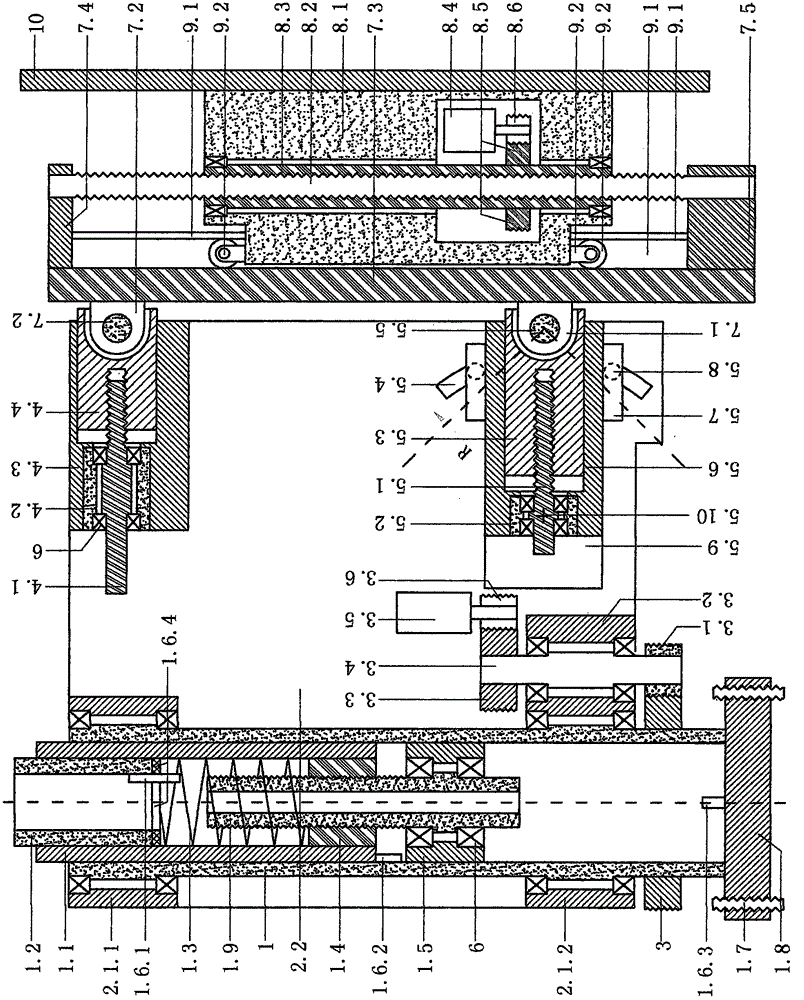

[0031] The main rod is composed of the base plate 1.8 and the height adjustment bolt 1.7; the main rod is composed of the main cylinder 1, the top cylinder 1.1, the contact cylinder 1.2, the spring 1.3, the nut cylinder 1.4, the main rod bearing seat 1.5, and the screw cylinder 1.9. the lifting part.

[0032] The screw barrel 1.9 is installed in the bearing seat 1.5 and the nut barrel 1.4 fixed in the inner hole of the main barrel 1. After the bolt barrel 1.9 is driven by power (commonly known knowledge, the figure is omitted), it generates a push / pull force on the nut barrel 1.4, driving the top barrel 1.1 Slide up and down along the axial direction of the main cylinder 1; when the top cylinder 1.1 is pushed up to a certain height by the bolt cylinder 1.9, the contact cylinder 1.2 on it contacts with the obstacle at the upper end and stops going up, and at the same time, the spring 1.3 of its elastic support body A downward back pressure is generated, and when the back pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com