Filter cloth rinser for vacuum filter and pressure filter

A technology of pressure filter and vacuum filter, which is applied in the direction of mobile filter element filter, filtration separation, chemical instruments and methods, etc., can solve the problems of filter hole blockage of filter cloth, difficulty in cleaning filter cloth, and reduction of filtration efficiency. , to achieve the effect of fast cleaning, flexible and fast operation, convenient installation, use and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail by the following examples.

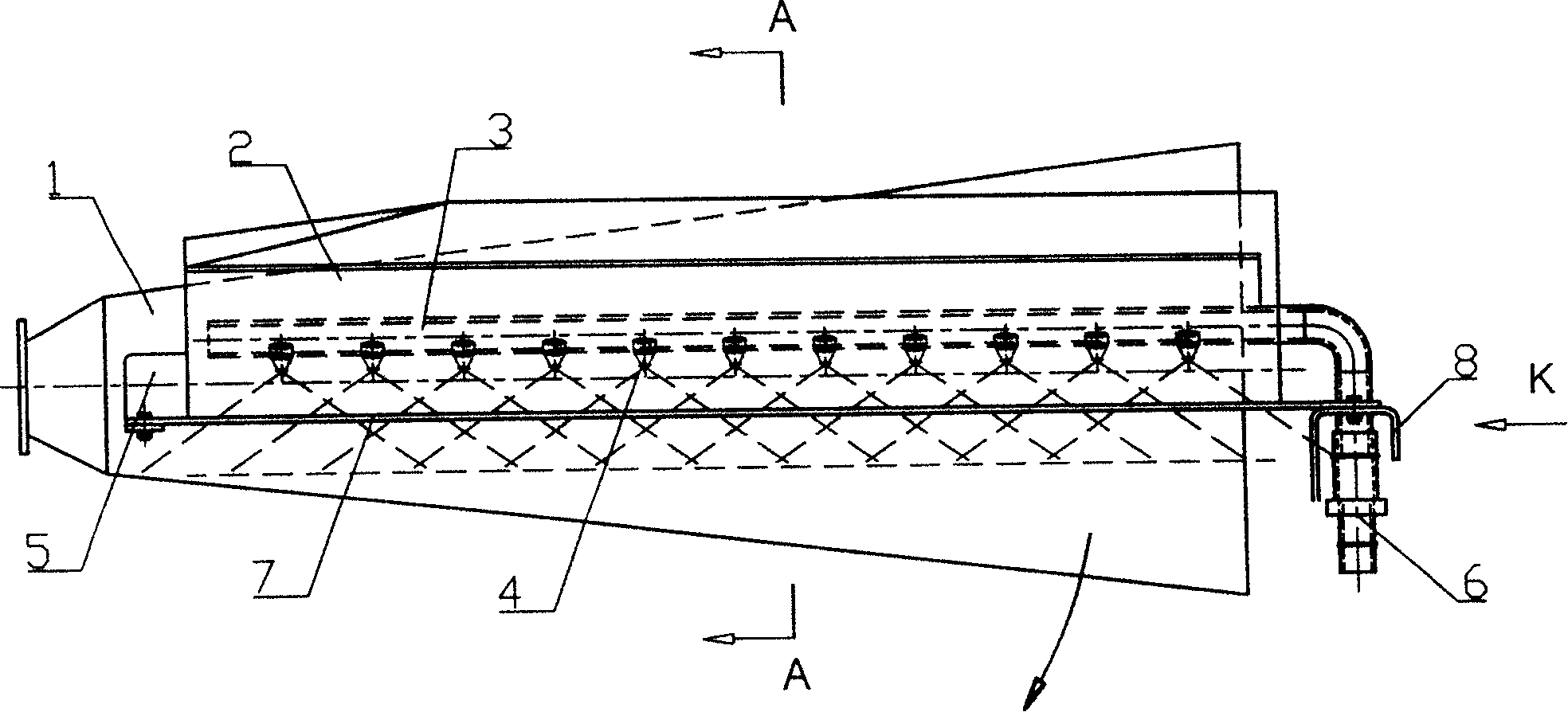

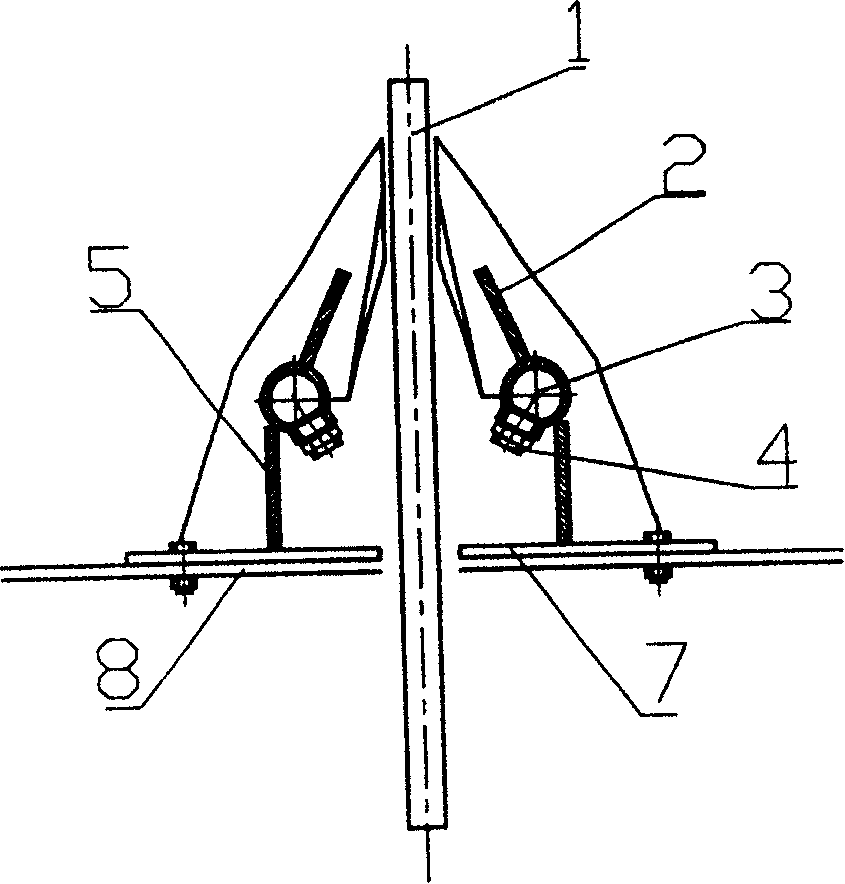

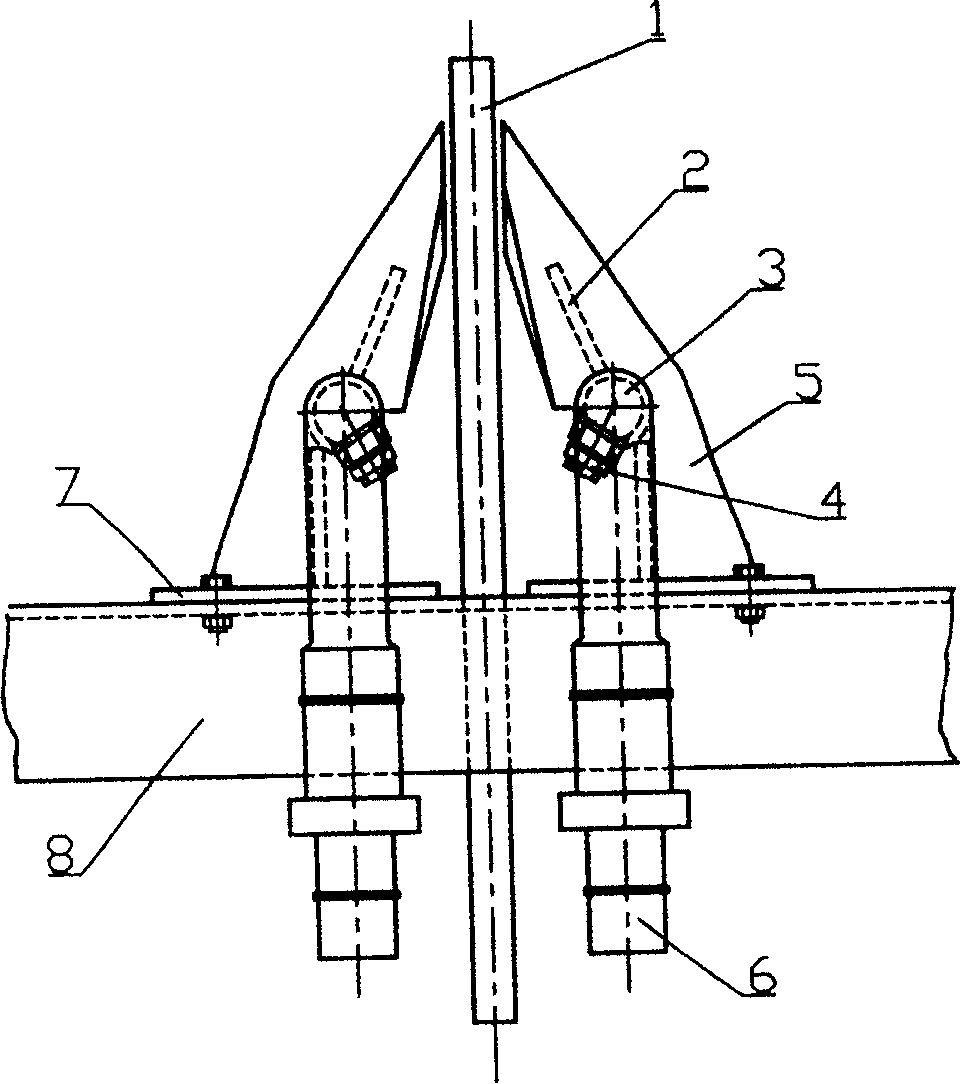

[0018] see figure 1 , figure 2 , image 3 As shown, a filter cloth cleaning device suitable for vacuum filters and pressurized filters consists of a filter cloth 1, a discharge scraper 2, a spray pipe 3, a nozzle 4, a knife seat 5, a water pipe 6, a fixed plate 7 and a base It consists of 8 seats. There are filter cloth cleaning devices with symmetrical structure on both sides of the filter cloth 1. The structure of the cleaning device on each side is as follows: a vertical metal knife seat 5 is welded on the fixed plate 7 along the length direction of the plate. There is a row of equidistant round through holes on the lower side of the shower pipe 3, and a nozzle 4 with an opening downward and oblique to the filter cloth 1 is threaded on each round through hole, and the top of the metal knife holder 5 is welded on a horizontally arranged On the outer lower side of the spray pipe 3, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com