Full-automatic hoisting conveying system before organic garbage spray explosion treatment

A technology before the treatment of organic waste, applied in the direction of lifting devices, etc., can solve problems such as low production efficiency, poor working environment, and prone to accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

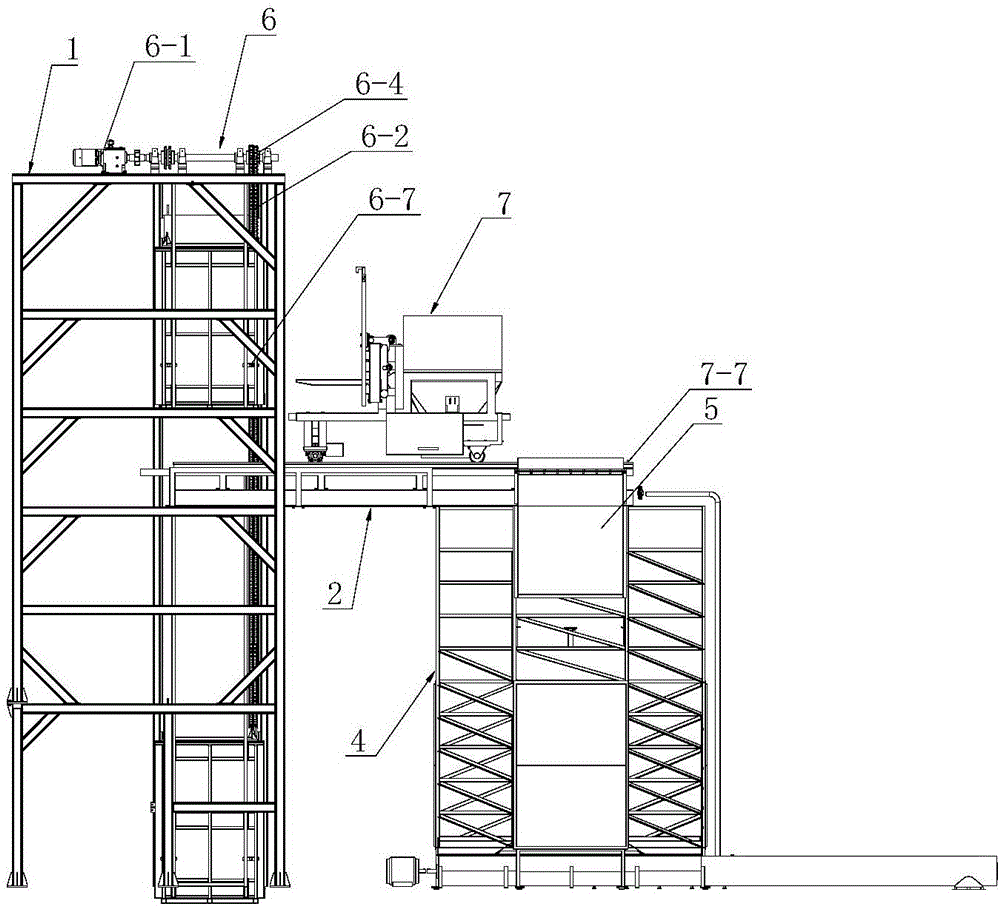

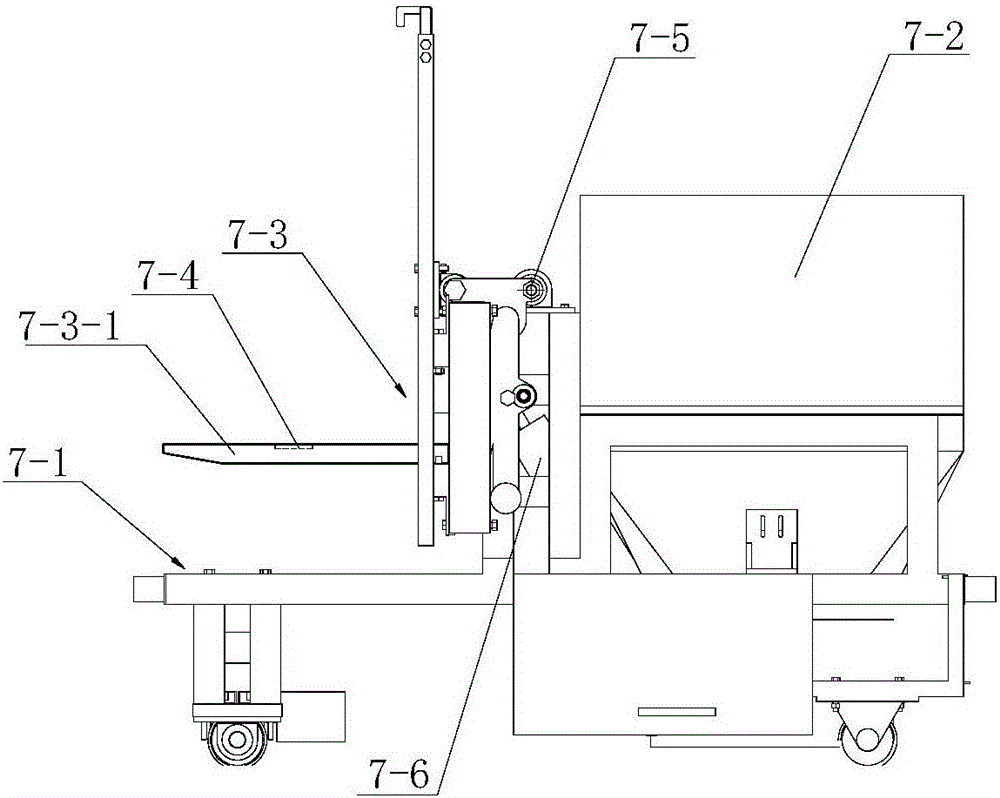

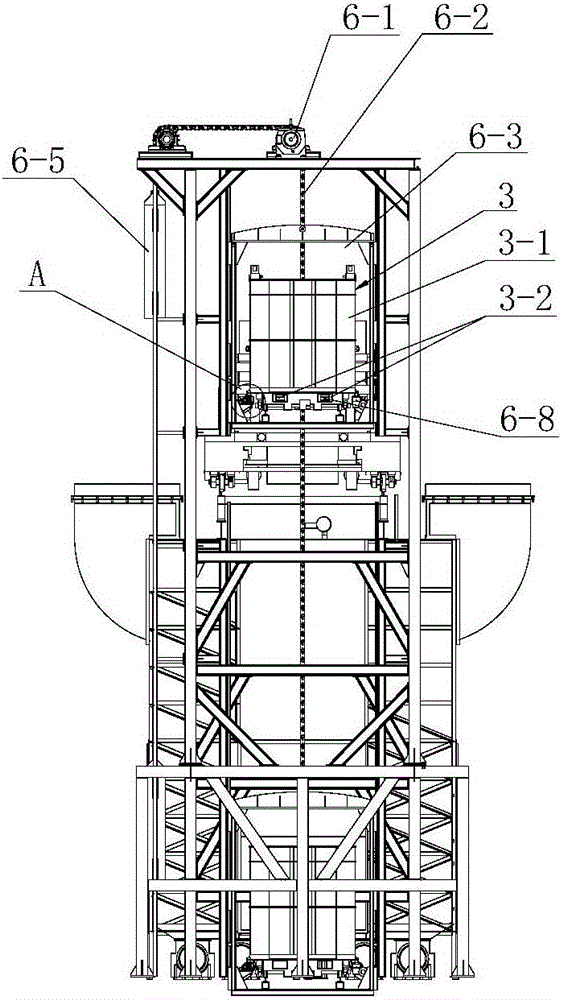

[0021] See Figure 1-5 , a fully automatic lifting and conveying system before spraying and blasting treatment of organic waste, comprising a lifting frame 1, a horizontal conveying frame 2 and a feeding barrel 3 for containing garbage, the two ends of the horizontal conveying frame are erected on the lifting frame and exposed Above the machine supporting frame 4, a violent machine 5 is installed on the upper end of the violent machine supporting frame. The lifting frame is provided with a lifting mechanism 6 that lifts the feeding barrel from a low position to a high position, and a horizontal conveying mechanism 7 that transports the feeding barrel lifted to a high position to the blasting position is provided on the horizontal conveying fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com