A direction-changing drill pipe power transmission device

A technology of power transmission device and drill pipe, which is applied in the direction of drilling equipment, earthwork drilling, drilling equipment and methods, etc., and can solve the problem of inability to realize the drill pipe and grouting pipe changing direction drilling and grouting, and the inability to use underground depth drilling Holes, inability to complete drilling and grouting, etc., to achieve the effect of low comprehensive construction cost, significant social benefits, and small traffic impact range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

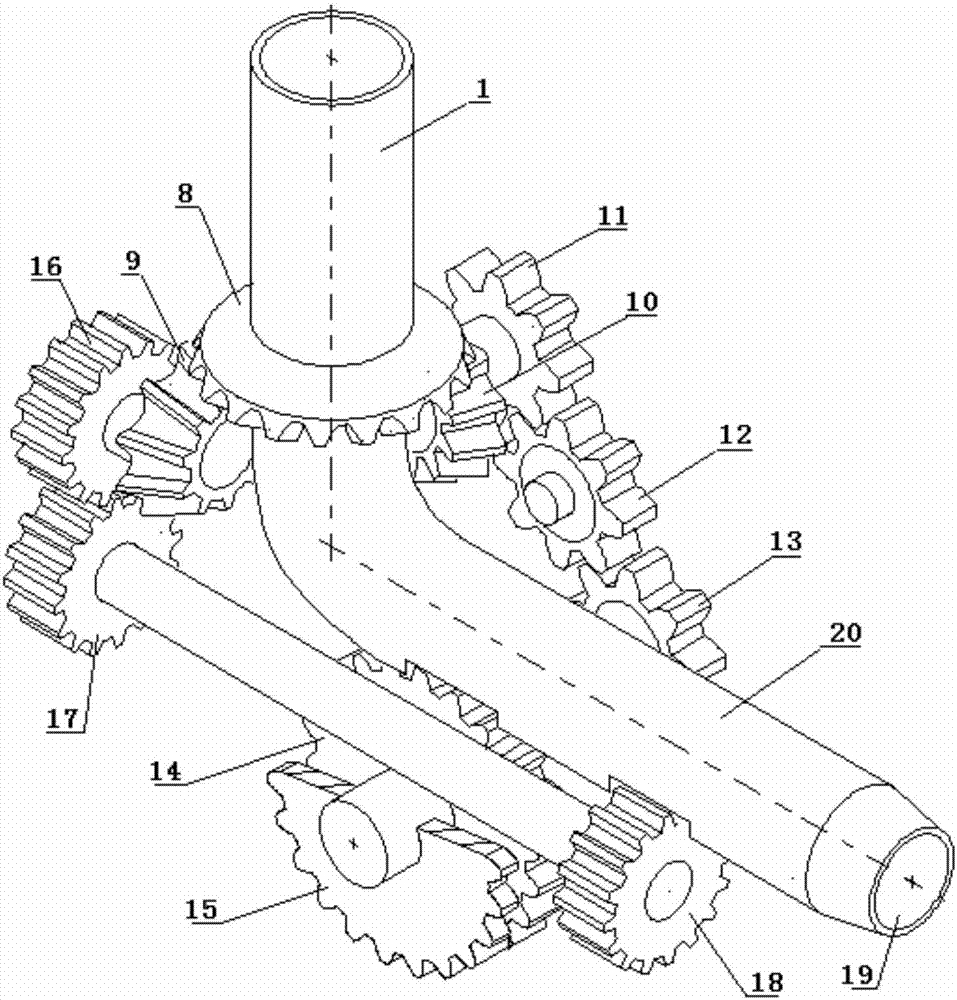

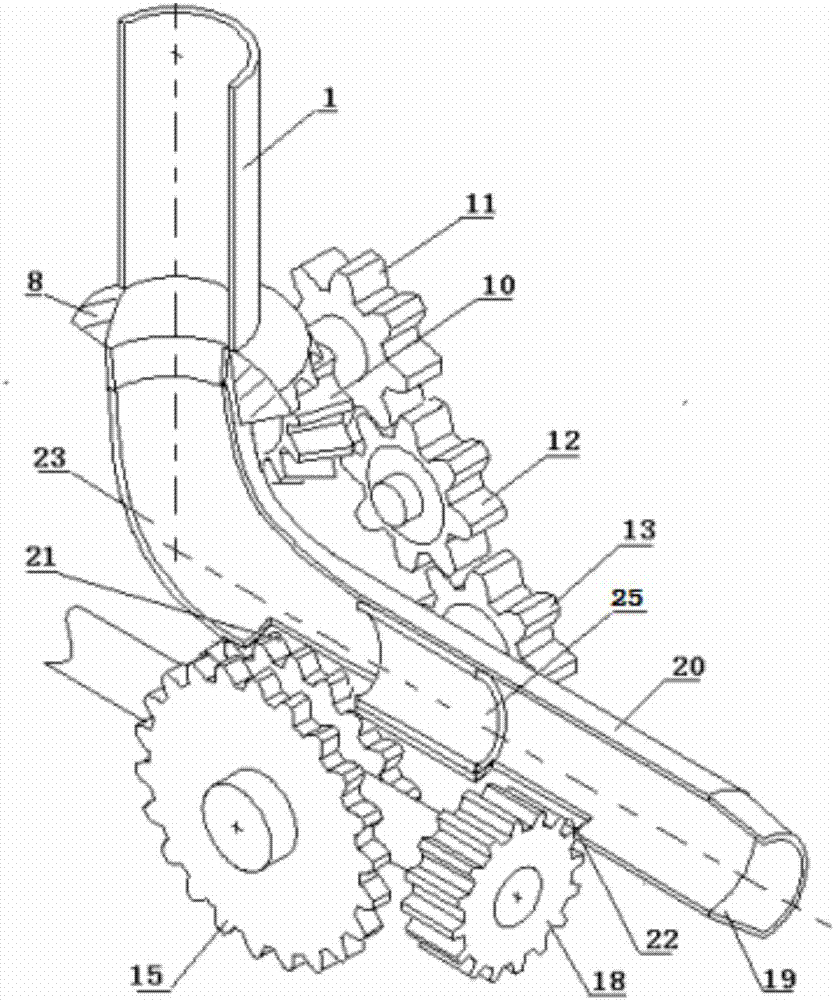

[0029] see figure 1 , figure 2 , image 3 , Fig. 4a, Fig. 4b and Fig. 4c, the power transmission device of the reversing drill pipe in this embodiment includes: a drill pipe channel, an assembled drill pipe and a transmission mechanism.

[0030] The drill pipe channel is the inlet pipe of the drill pipe with a section of vertical straight pipe 1, a section of straight pipe arranged in a set direction as the guide track 20, and the front end of the guide track is the track outlet 19, between the vertical straight pipe 1 and The guide rails 20 are smoothly transitioned and connected by an arc track 23 to form a through drill pipe channel with steering. The arc track 23 is used to realize the direction change of the drill pipe track. The turning angle should be greater than 90°; the vertical straight pipe 1 in the drill pipe channel is set as a rotatable pipe, and the motor provides driving force for the vertical straight pipe 1; the assembled drill pipe is composed of at leas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com