Cable terminal tightening device

A fastening device and cable terminal technology, which is applied in the direction of cable suspension device, cable installation, electrical components, etc., can solve the problems of falling off, difficult operation, large randomness, etc., and achieve simple structure, good firmness, and easy to use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

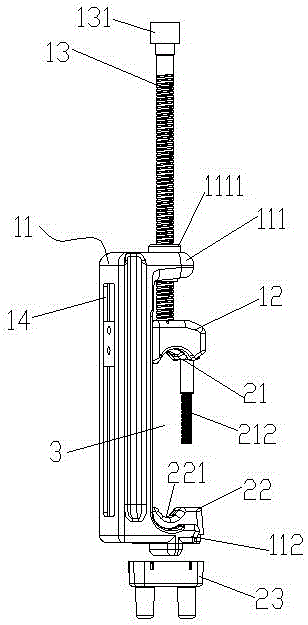

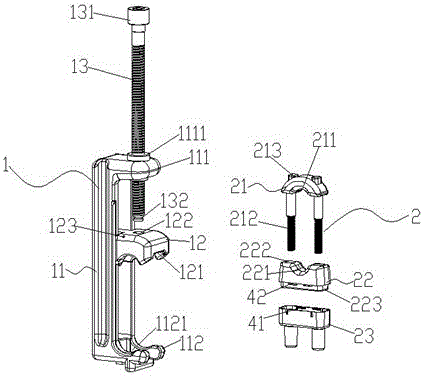

[0033] Such as Figure 1-2As shown, a cable terminal fastening device includes a fastening device 1 and a fastening clamp 2. The fastening device 1 includes a crimping body 11, a dynamic pressure block 12 and a crimping screw 13. The crimping body 11 includes oppositely arranged The connection part 111 and the support part 112, the compression screw 13 is threadedly connected with the connection part 111, one end of the compression screw 13 is rotatably connected with the dynamic pressure block 12, and the other end is provided with a rotating part 131, and the dynamic pressure block 12 is located at Between the connecting part 111 and the supporting part 112 and opposite to the supporting part 112, the crimping body 11 is provided with a function to limit the dynamic pressure block 12 to only perform linear reciprocating movement between the connecting part 111 and the supporting part 112 and cannot rotate. The limit mechanism can adjust the linear movement of the dynamic pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com