Automatic grader for soft-package batteries

A technology of automatic grading and soft-pack batteries, applied in the field of grading machines, can solve the problems of loss of quality and sales in the application of battery packs, unsuitable for large-scale production needs, and large human factors in grading quality and efficiency, so as to achieve fast and efficient automatic grading , fast battery grading, and the effect of reducing the number of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

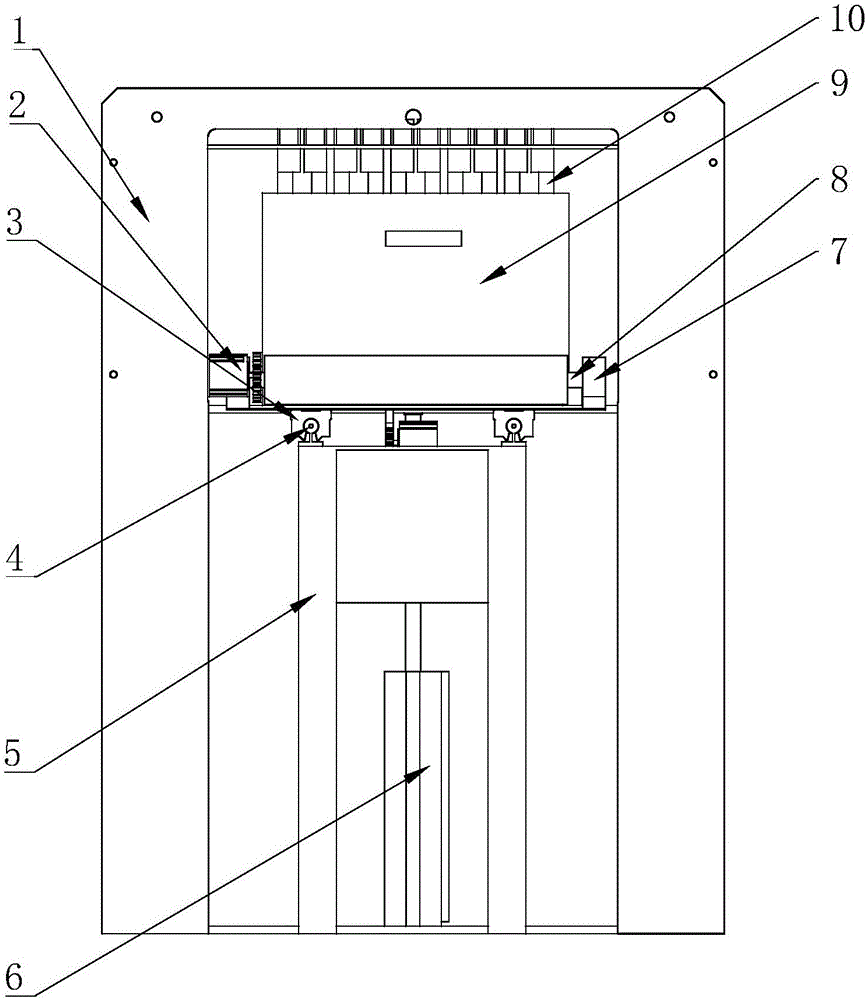

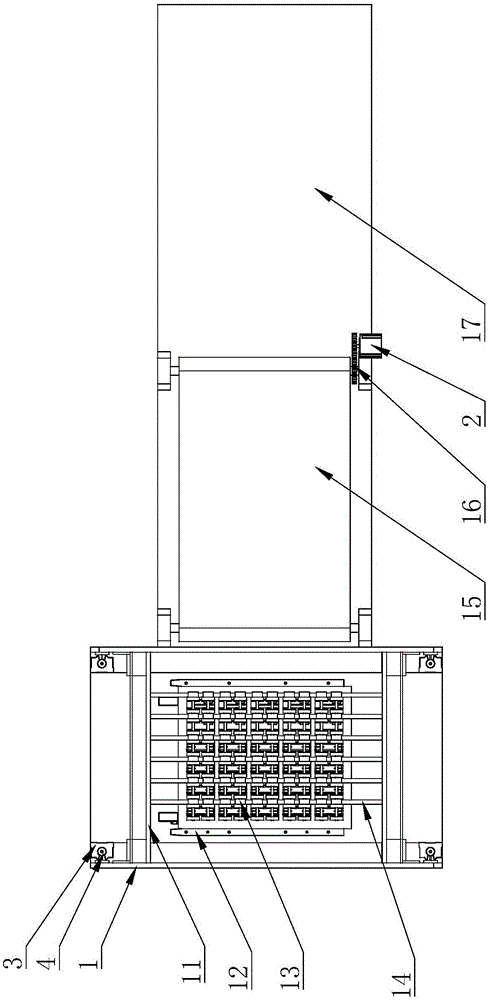

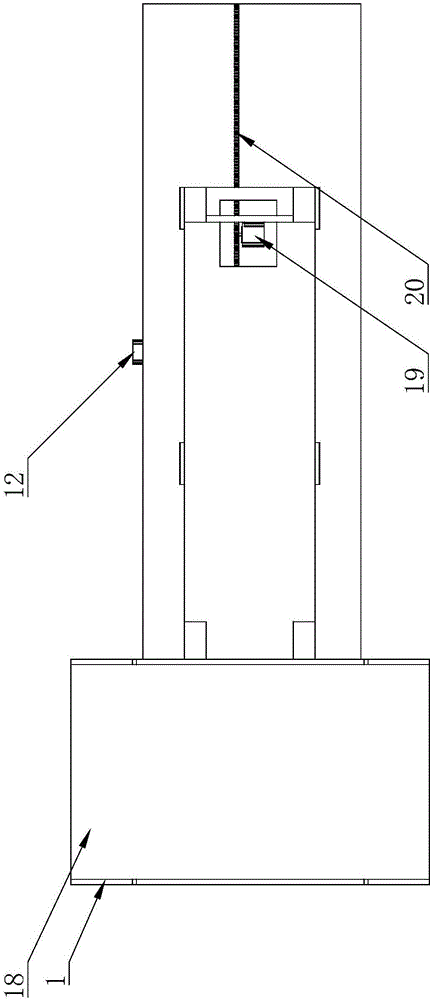

[0032] The present invention is an automatic grading machine for soft pack batteries, such as figure 1 , 2 , 3, 4, 5, 6, 7, 9, 10.

[0033] The above-mentioned Y is 2. .

[0034] The above-mentioned manipulator is the electric manipulator 13 .

[0035] The above-mentioned in-position switch, detection switch 37 and positioning switch 36 are limit switches.

[0036] In the above-mentioned transmission mechanism, a rack is fixedly installed under the conveying plate; a rack motor is fixedly installed on the conveying frame, a motor gear is installed on the shaft of the rack motor, and the motor gear is connected with the rack in a geared transmission.

[0037] The above-mentioned transmission device is a gear transmission.

[0038] The above-mentioned automatic grading machine for soft pack batteries includes a conveying module, a rack modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com