Felt for papermaking and its manufacturing method

A manufacturing method and felt technology, applied in papermaking, paper machine, paper machine wet end, etc., can solve the problems of poor production efficiency and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

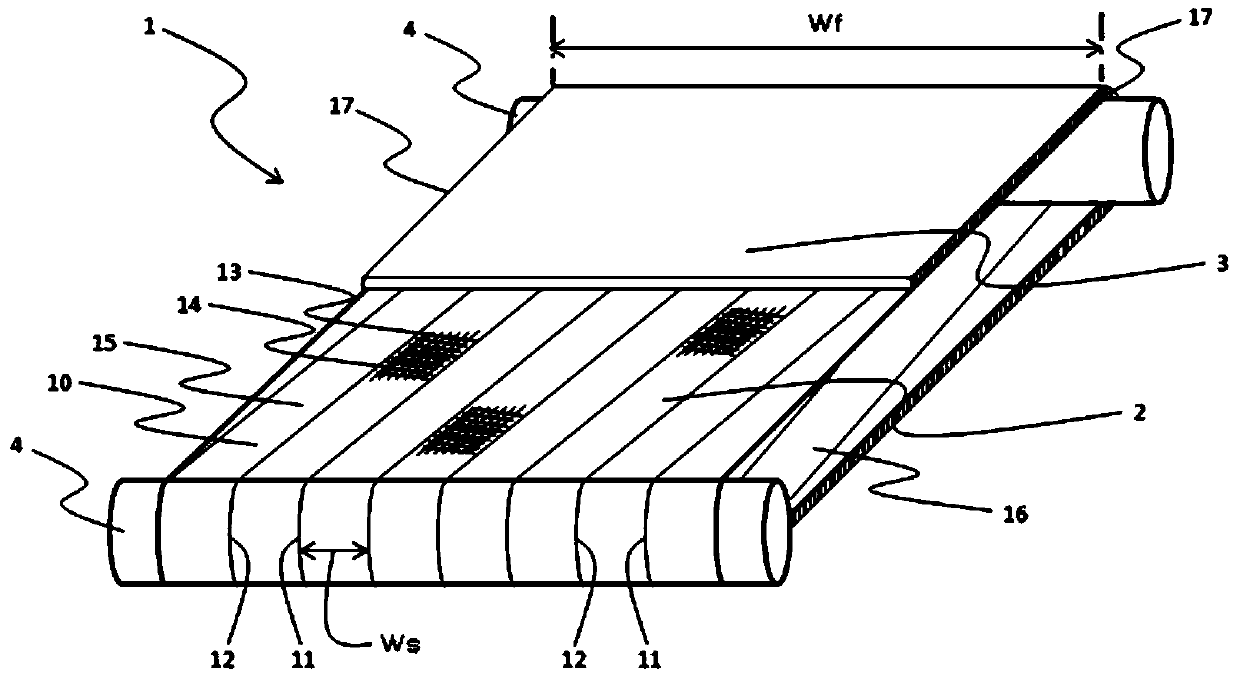

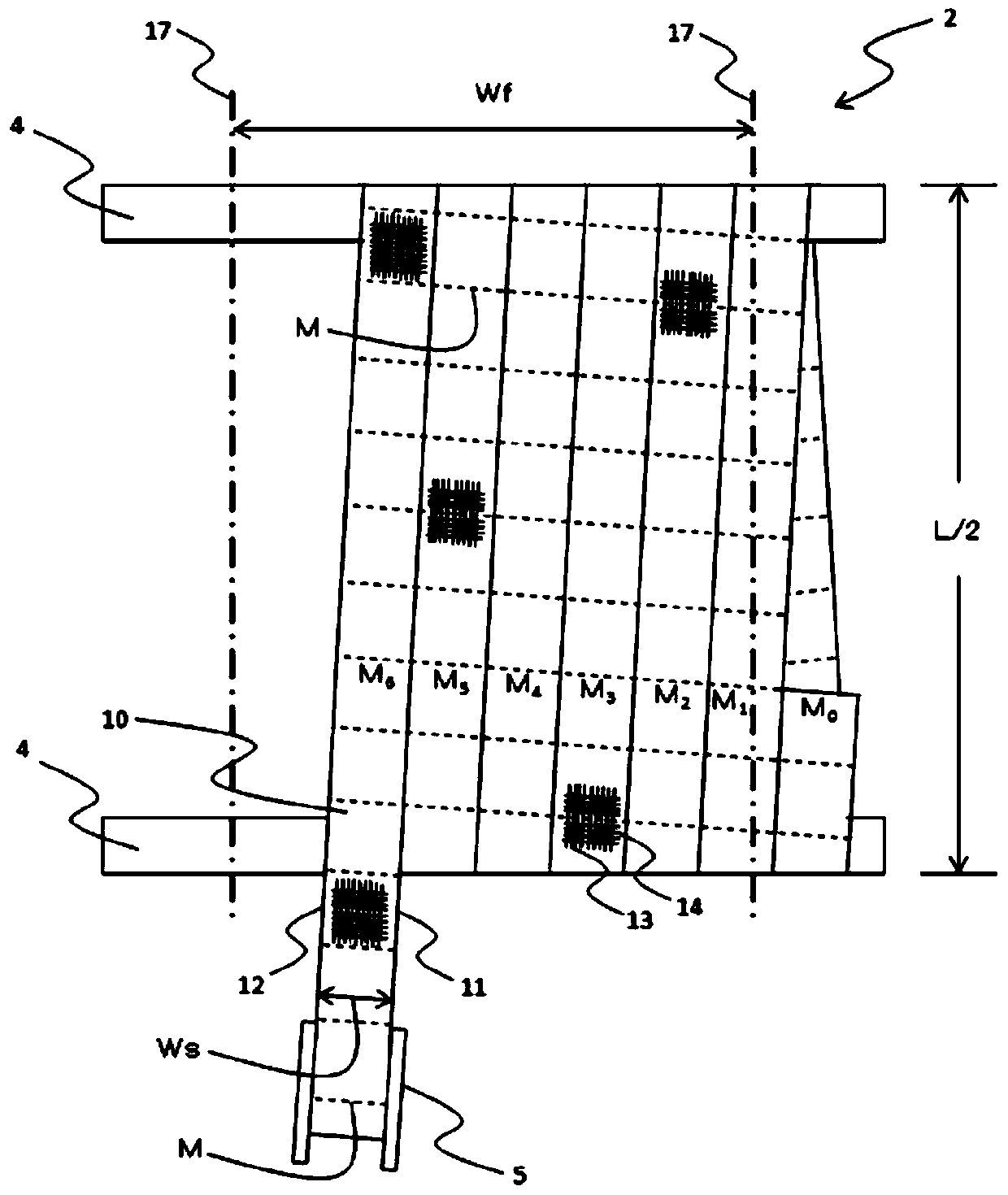

[0059] Preferred embodiments of the present invention will be described in detail below with reference to the drawings.

[0060] figure 1 It is a perspective view which shows an example of the felt for papermaking which concerns on one Embodiment of this invention. This felt 1 has a base fabric layer 2 and a tie layer 3 integrally formed with the base fabric layer 2 . The base fabric layer 2 is a belt-shaped body 10 having a plurality of bottom warp threads 13, a plurality of bottom weft threads 14, a first side edge 11, and a second side edge 12, and the width Ws is smaller than the width Wf of the felt 1 for papermaking. The first side edge 11 and the second side edge 12 are spirally wound adjacent to each other, and the side edges (adjacent first side edge 11 and second side edge 12 ) are joined together. Also, only a part of the bottom warps 13 and the bottom wefts 14 are drawn in the figure.

[0061] Needless to say, the bottom warp 13 of the strip 10 and the direction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com