Automatic steel plate cropping material feeding mechanism

An automatic feeding and steel plate technology, applied in the direction of shearing devices, shearing machine accessories, feeding devices, etc., can solve the problems of low production efficiency and billet pass rate, safety and hidden dangers, etc., and achieve high production efficiency and length Uniform size and improved pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

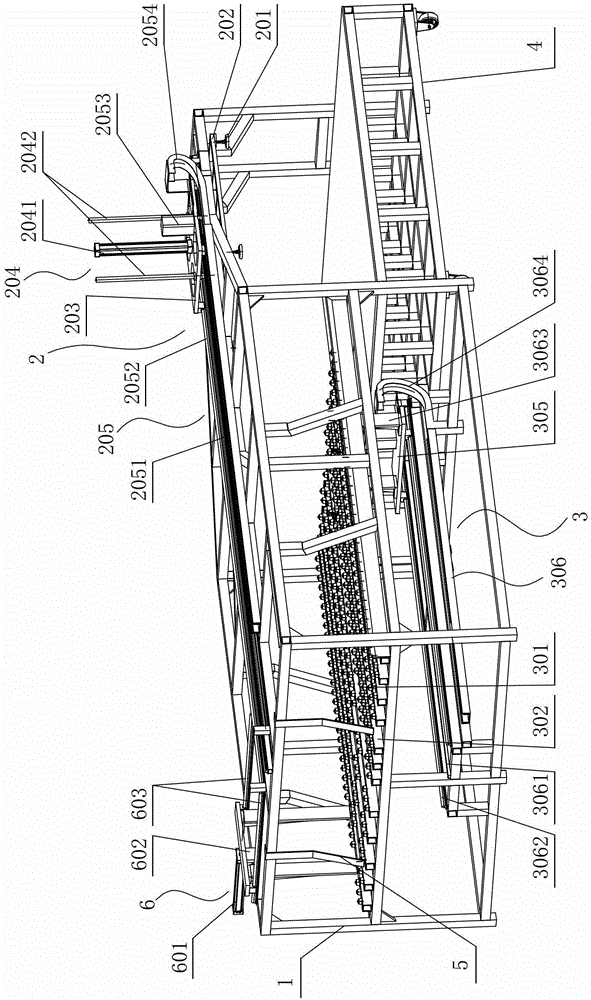

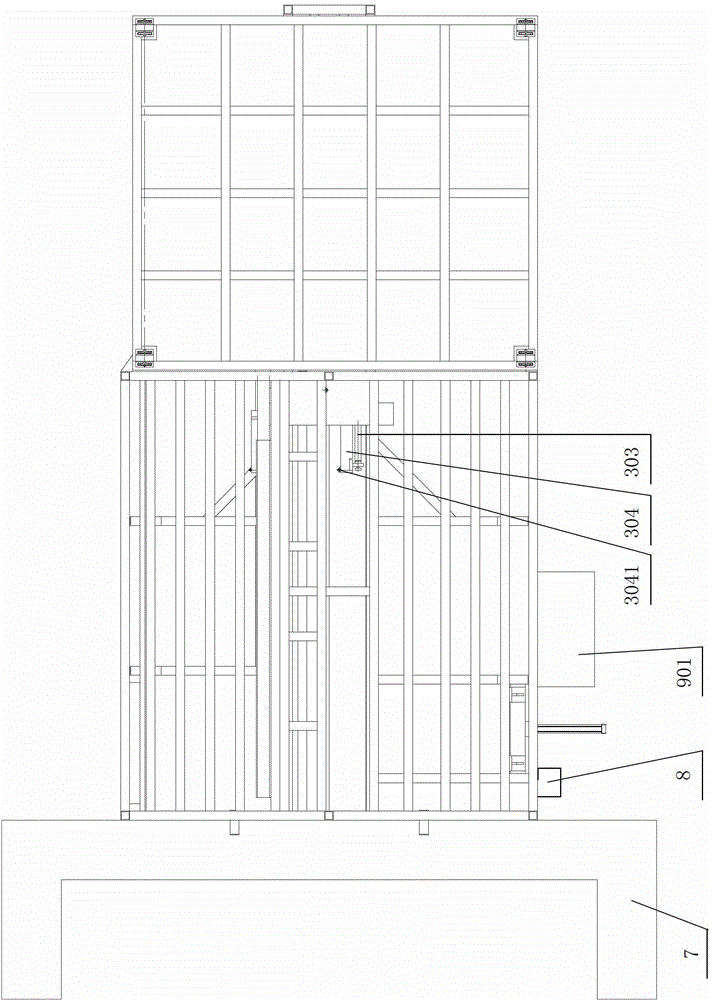

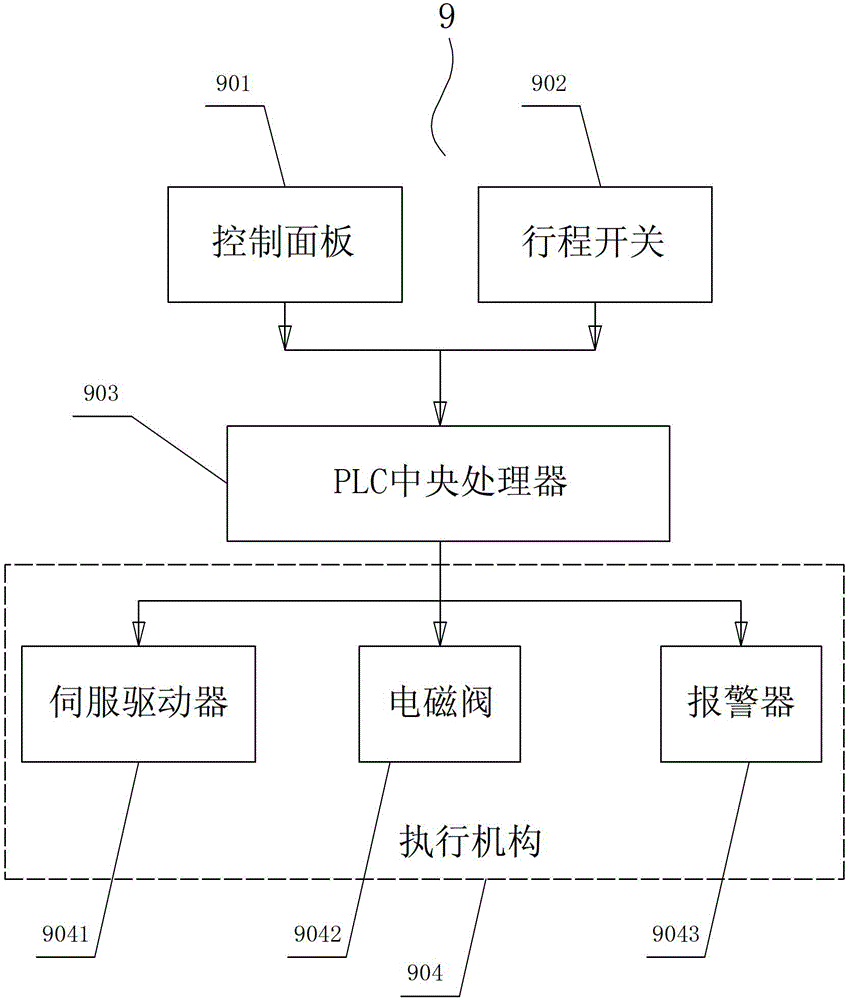

[0047] Figure 1-Figure 2Disclosed in is a steel plate shearing automatic feeding mechanism, including a frame 1, a feeding device 2, a feeding device 3, and a PLC control integrated system 9 for controlling the feeding device 2 and the feeding device 3, the feeding device 2 is installed on the top of the frame 1, and the feeding device 3 is installed in the middle of one end of the frame 1, and the feeding device 3 is connected with the feeding port of the shearing machine 7; the other end of the frame 4 is provided with a useful The plate trolley 4 for stacking steel plates.

[0048] The feeding device 2 includes a vacuum suction cup 201, a material suction frame 202, a trolley frame 203, a lifting mechanism 204 and a horizontal conveying mechanism 205, and the described vacuum suction cup 201 is fixed below the material suction frame 202, and the described lifting mechanism 204 comprises telescopic cylinder 2041, lifting guide column 2042, and described telescopic cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com