Temperature measuring device and measuring method for thermal analyzer

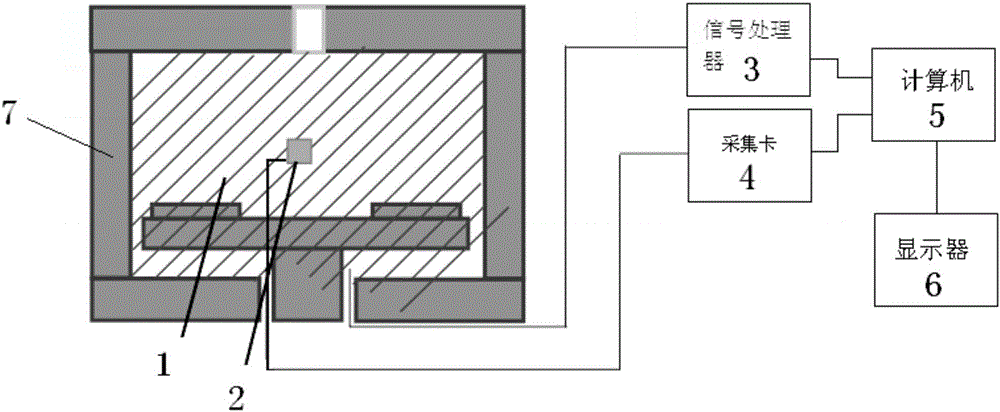

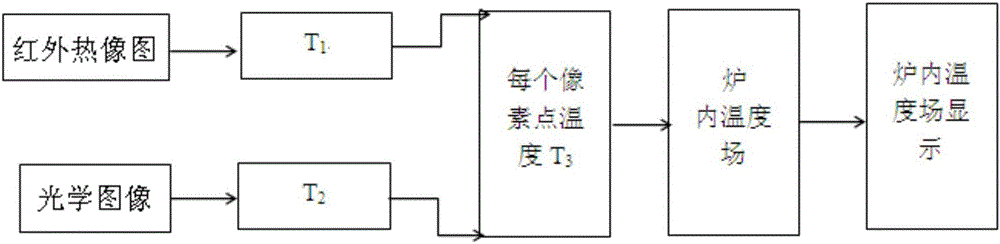

A technology of temperature measurement and thermal analyzer, applied in the direction of electric radiation detectors, etc., can solve the problems of not being able to obtain the overall temperature of the thermal analysis instrument and the interference of the measured temperature, and achieve the effect of not affecting the temperature field distribution and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

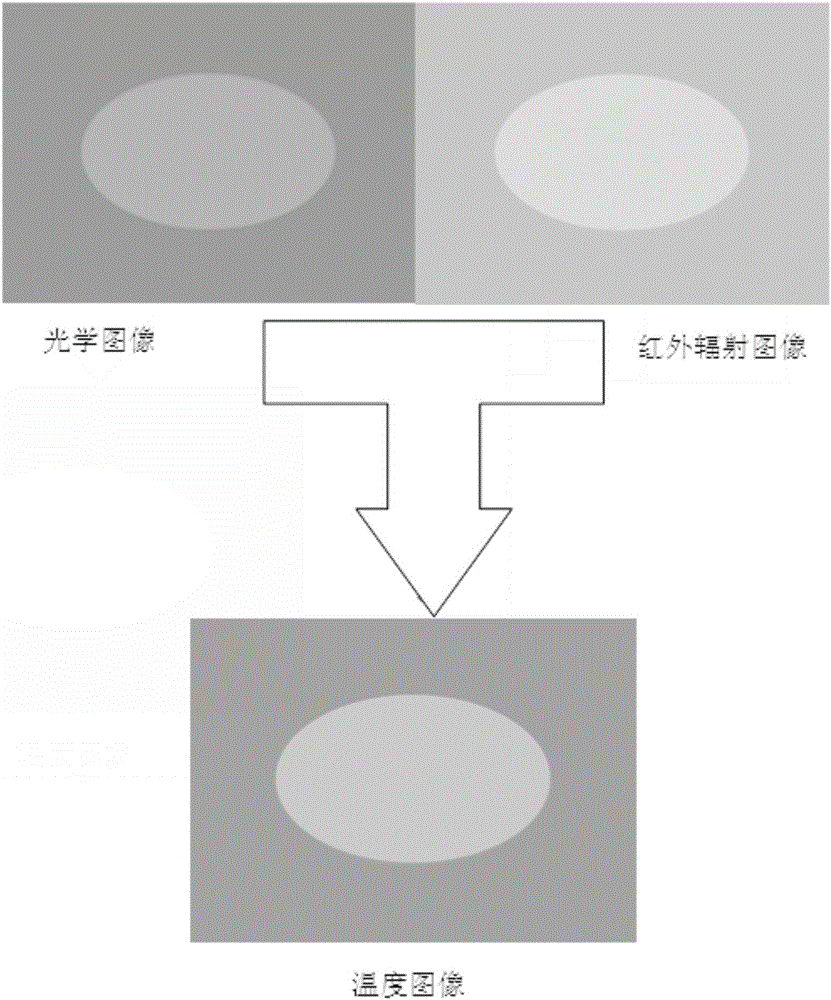

[0053] The color fusion image finally obtained by the present invention includes both infrared radiation information in the heating furnace and optical information, that is, two main electromagnetic waves radiated during the heating process. It can well characterize the temperature condition in the furnace. For example, if image 3 As shown, when the temperature is low, the infrared image is obtained, the middle ellipse is yellow, and the surrounding is orange, and different colors represent different temperatures. When the temperature rises, the radiated electromagnetic waves are mainly displayed in the form of visible light. In the obtained optical image, the middle ellipse and the surrounding area are red and orange respectively. The inner wall of the furnace heated to a certain temperature can be regarded as a light source. Different colors reflect different temperature. In the fused image, the part with high temperature is displayed in red tone, and the part with low te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com