Novel hairbrush pipe scraping device

A brush and scraper technology, which is applied in the field of new brush scraper devices, to achieve the effects of avoiding underground accidents, fixing firmly, and solving the problem of anti-jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

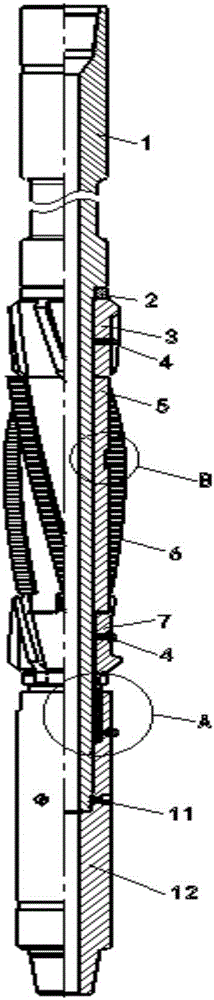

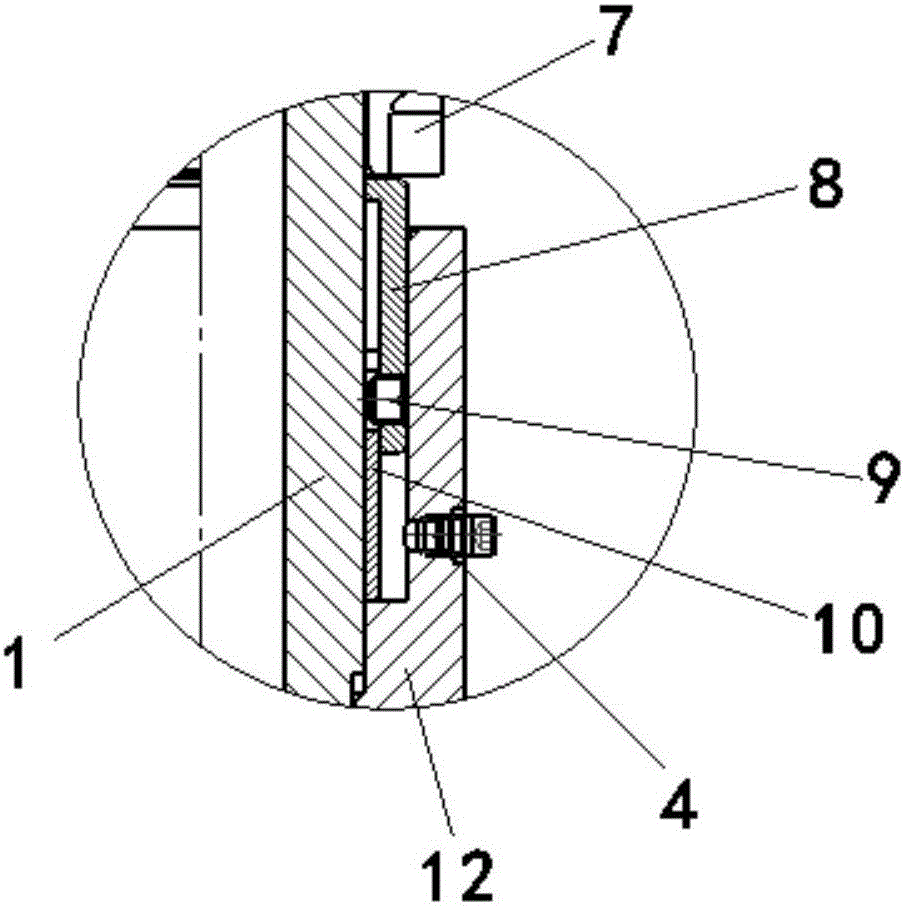

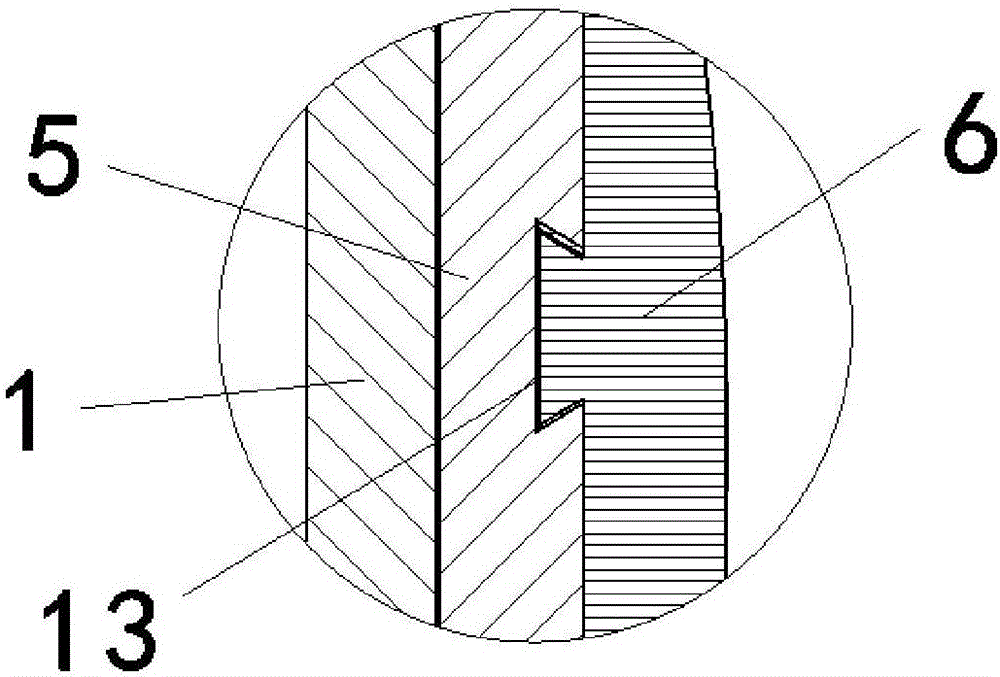

[0019] Embodiment of the present invention: the structure schematic diagram of novel hair brush scraper device is as figure 1 As shown, it includes the mandrel 1 and the lower joint 12 connected to the lower end of the mandrel 1, and the side wall of the connecting section between the lower joint 12 and the mandrel 1 is provided with an anti-drop pin 11; the outer wall of the mandrel 1 is covered with a brush Set of 5, see Figure 3-6 , the upper outer wall of the brush cover 5 is evenly provided with three spiral grooves 13 with dovetail-shaped cross-sections, the brush 6 is fixed in the spiral groove 13, and the upper centering sleeve 3 and The lower centralizing sleeve 7, the side walls of the upper centralizing sleeve 3 and the lower centra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com