Heating control method and system of electronic cooker

A technology for heating control and cooking utensils, which is applied in control/regulation systems, non-electric variable control, temperature control using electric means, etc., can solve the problems of raw rice, browned rice, boiled, etc., and achieves the effect of good cooking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

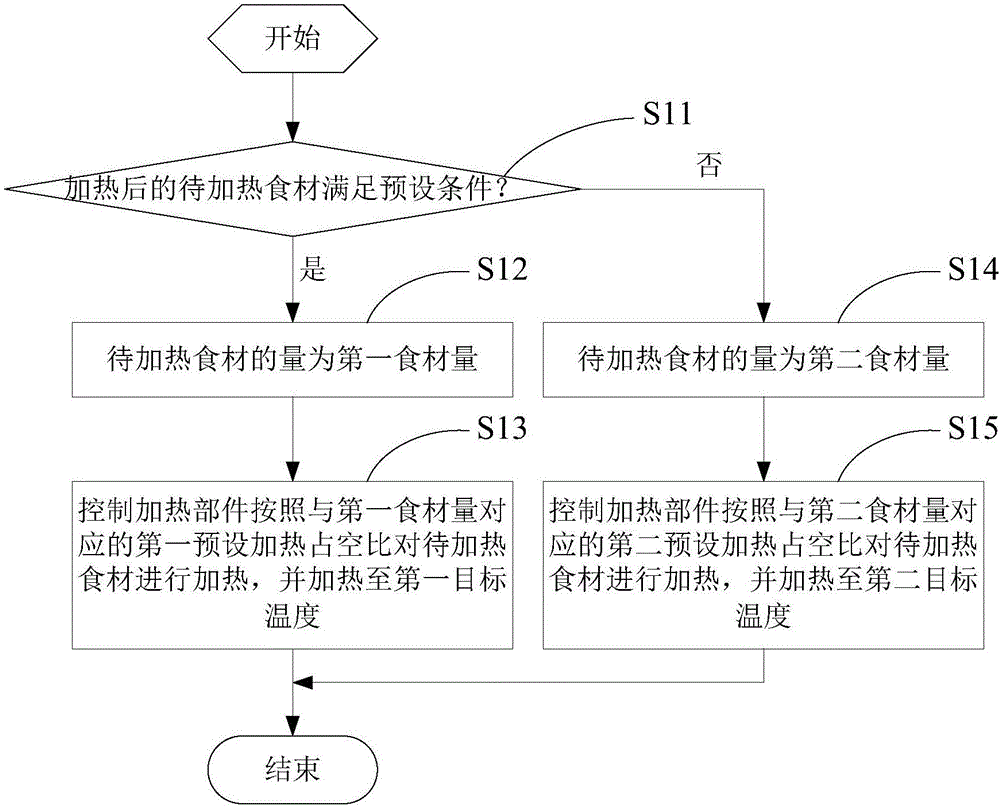

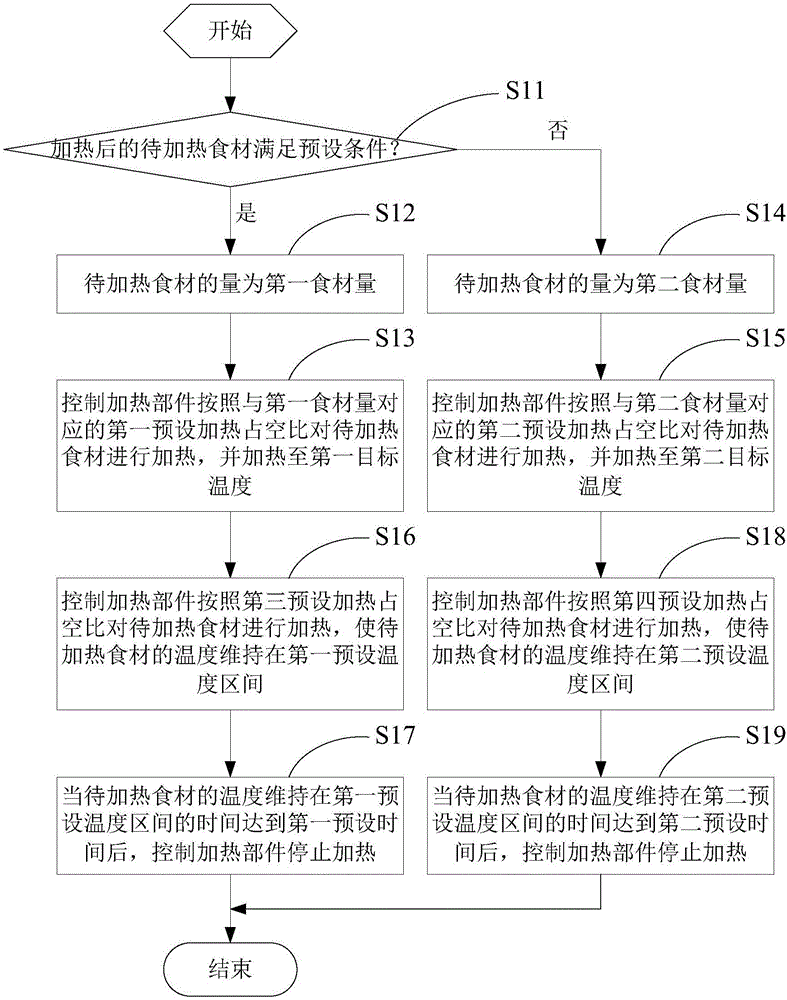

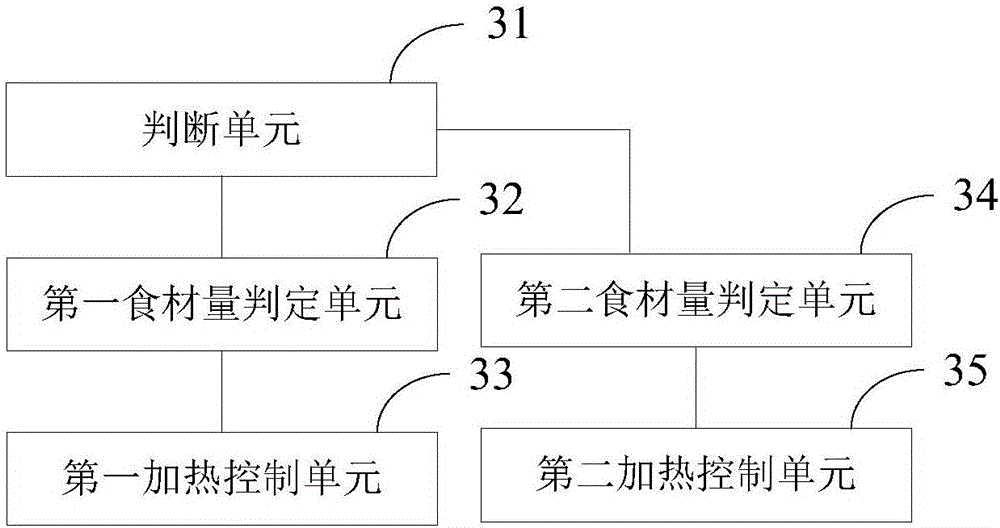

Method used

Image

Examples

Embodiment 1

[0105] Acquire the actual temperature of the food to be heated after heating for the third preset time in the first preset heating method starting from the first initial target temperature; It is determined that the preset condition is satisfied at the first set temperature.

[0106] It should be noted that after it is determined that the food to be heated satisfies the preset condition, the food to be heated will continue to be heated until the temperature of the food to be heated reaches the first target temperature (or the second target temperature), therefore, in order to ensure The steps after step S11 can continue to be executed. In this embodiment, the actual temperature of the food to be heated after the third preset time must be lower than the first target temperature (or the second target temperature).

[0107] Since the second target temperature is lower than the first target temperature, it is only necessary to ensure that the actual temperature of the food to be h...

Embodiment 2

[0112] Obtain the heating time required for the food to be heated to be heated to the third preset temperature in the second preset heating method starting from the second initial target temperature; judge the relationship between the heating time and the set time, and When the time is not lower than the set time, it is determined that the preset condition is met.

[0113] Wherein, the second initial target temperature may be the initial target temperature in the above embodiment, and the third preset temperature is lower than the second target temperature (for specific reasons, please refer to Embodiment 1).

[0114] The specific value of the set time depends on actual needs.

[0115] Specifically, firstly, the food to be heated is heated to the second initial target temperature, and then the heating time required for the food to be heated to be heated to the third preset temperature in the second preset heating method from the second initial target temperature is acquired, w...

Embodiment 3

[0117] Acquire the pressure value of the food to be heated when it is heated to the third target temperature in a third preset heating method starting from the third initial target temperature; judge the relationship between the pressure value and the preset pressure value, and calculate the When it is less than the preset pressure value, it is determined that the preset condition is met.

[0118] Wherein, the third initial target temperature may be the initial target temperature in the above embodiment, and the third target temperature is lower than the second target temperature (for specific reasons, please refer to Embodiment 1).

[0119] Specifically, the food to be heated is first heated to the third initial target temperature, and then the pressure value of the food to be heated when the food is heated to the third target temperature in the third preset heating mode from the third initial target temperature is obtained. When the pressure value When the pressure is less t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap