Harmonic management device for intermediate frequency furnace

A technology for harmonic control and intermediate frequency furnace, which is applied to harmonic reduction devices and AC networks to reduce harmonics/ripples, etc. wave effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings of the specification.

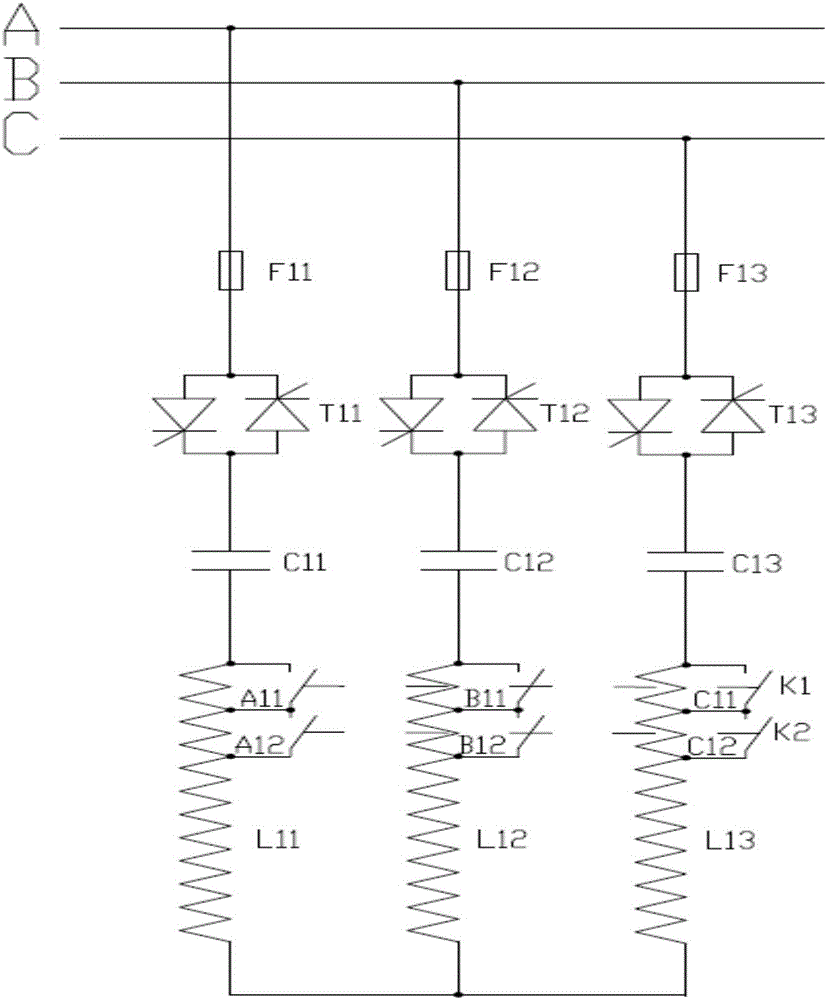

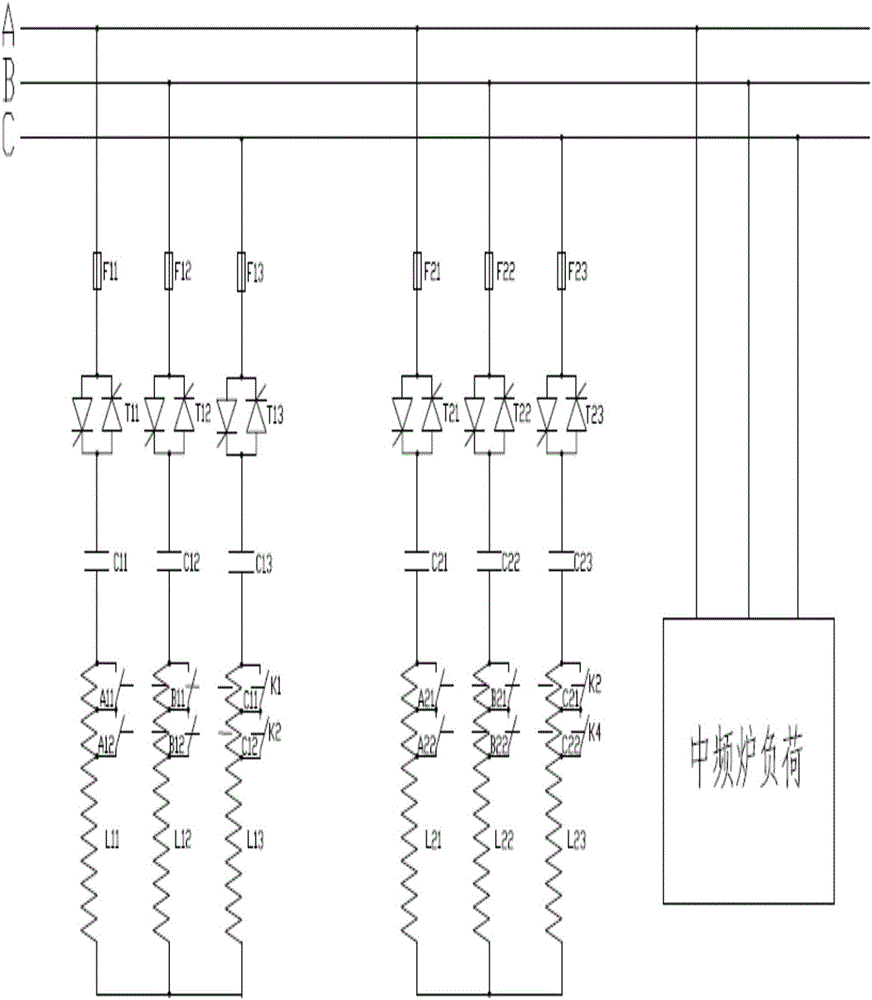

[0018] Such as figure 1 As shown, one of the LC filter circuit structure diagrams in a harmonic control device for an intermediate frequency furnace of the present invention includes three-phase power lines A-phase, B-phase and C-phase, and the three-phase power line A phase and fuse F11, Anti-parallel thyristor T11 and filter capacitor C11 are connected in series; Phase B of the three-phase power line is in series with fuse F12, anti-parallel thyristor T12, and filter capacitor C12; Phase C of the three-phase power line is connected with fuse F13, anti-parallel thyristor T13, and filter The capacitor C13 is connected in series; the output ends of the filter capacitors C11, C12, and C13 are electrically connected to the input ends of the filter windings of the three-phase filter reactor; the three-phase filter reactors are filter reactor L11 and filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com