Full Ceramic Gear Roll Mill

A gear roller and pulverizer technology, applied in the field of pulverized pulverizers, can solve the problem of no effective treatment method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

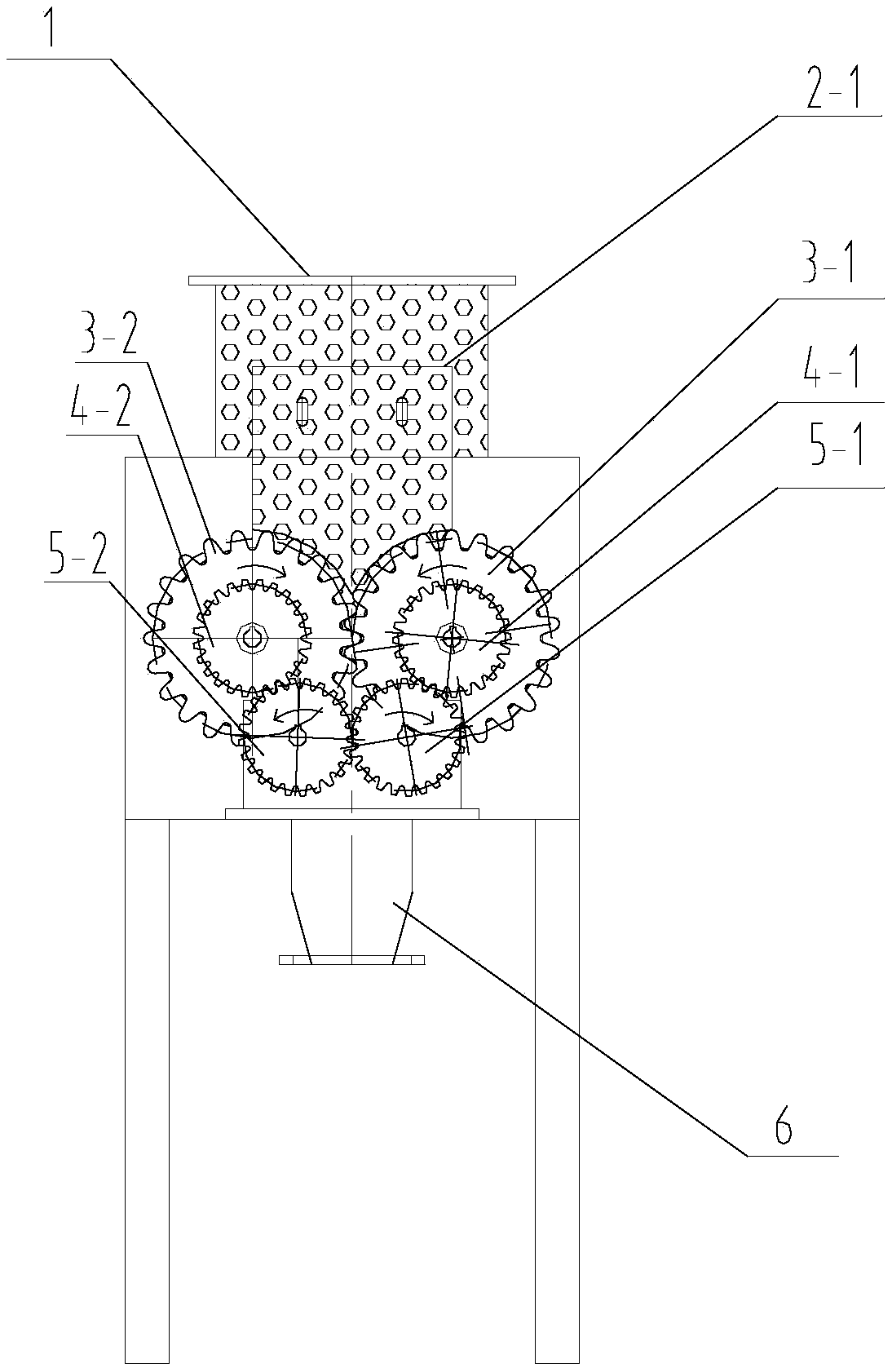

[0020] Embodiment 1: The all-ceramic gear roller pulverizer provided in this embodiment, the structural diagram is as follows figure 1 As shown, it includes a fuselage, a lower hopper 1 and a discharge port 6, the lower hopper 1 is located at the top of the fuselage, the discharge port is located at the bottom of the fuselage, a crushing chamber is provided in the fuselage, and the crushed A pair of oppositely rotating ceramic gear rollers are arranged above the discharge port 6 in the cavity, and the material falls into the gap between the two tooth surfaces of the pair of ceramic gear rollers and is crushed and crushed by the occlusal force of the two tooth surfaces.

[0021] The pair of ceramic gear rollers includes the first ceramic gear roller 3-1 and the second ceramic gear roller 3-2 driven by the pulverizing tooth roller transmission device. When there is no material filling, the pair of ceramic gear rollers are in a false meshing state. The pair of ceramic gear roller...

Embodiment 2

[0028] Embodiment 2: structure is basically the same as Embodiment 1, and the similarity is no longer repeated, and the difference is:

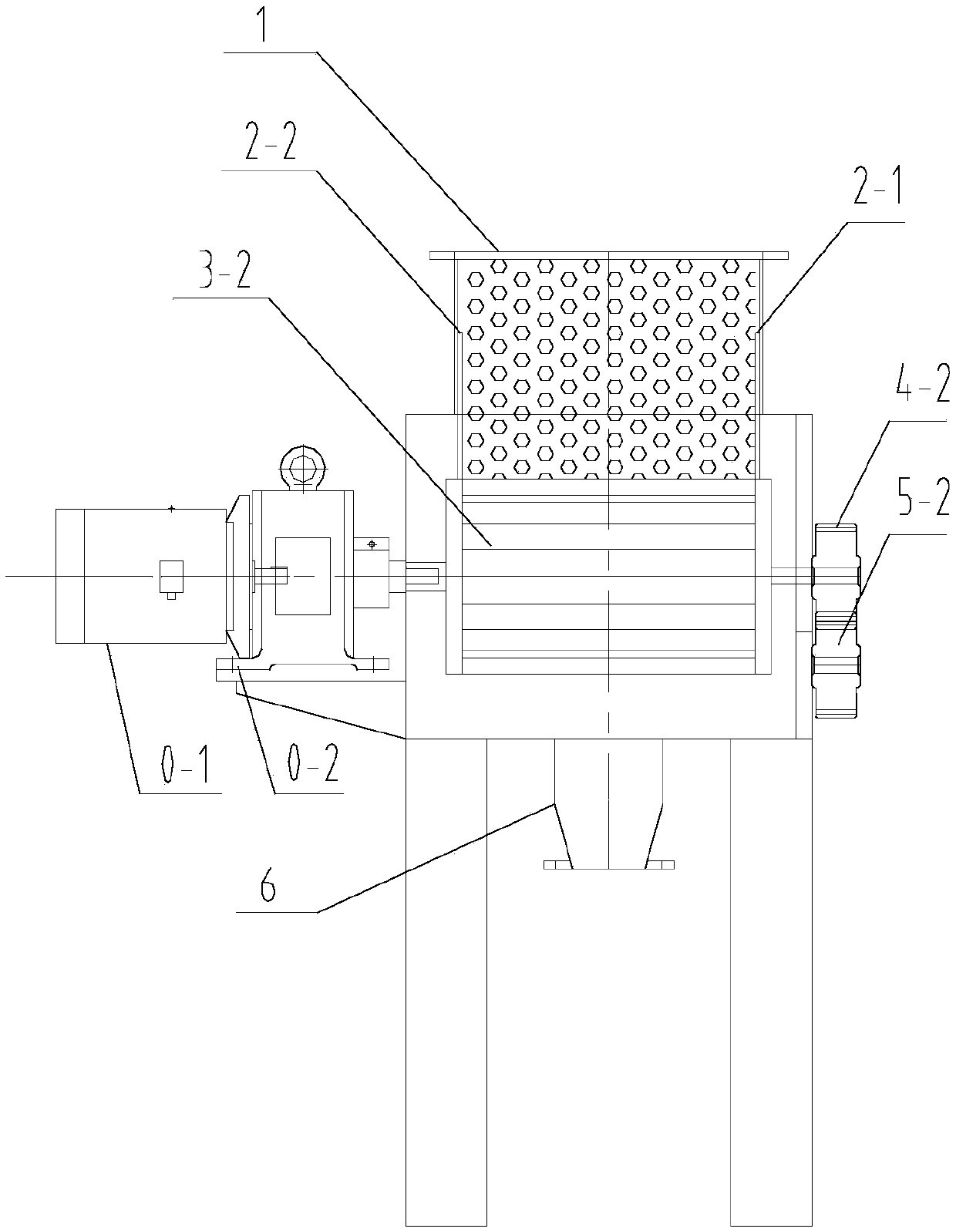

[0029] In Embodiment 2, only the first main shaft is drivingly connected to the motor among the first main shaft and the second main shaft. Specifically: if figure 2 As shown, one end of the first main shaft is driven and connected to the motor 0-1 through the reducer 0-2, while the first ceramic gear roller 3-1 is fixedly installed on the first main shaft, and the other end of the first main shaft is fixedly provided with the second A driving wheel 4-1.

[0030] Wherein, the first ceramic gear roller 3-1 and the second ceramic gear roller 3-2 are driven by the pulverizing gear roller transmission device to rotate inwardly.

[0031] At the same time, the inner wall of the feed port is equipped with ceramic lining or high wear-resistant organic matter. The fuselage includes a first arc-shaped shutter 2-1 and a first arc-shaped gate 2-1, wh...

Embodiment 3

[0034] Embodiment 3: structure is basically the same as Embodiment 1, and the similarity is no longer repeated, and the difference is:

[0035] The motor is a geared motor.

[0036] The fuselage includes a first arc-shaped shutter 2-1 and a first arc-shaped gate 2-1, which are oppositely arranged and located in the middle of the two ends of the first and second ceramic gear rollers, and are used to prevent materials from overflowing to both ends of the first and second ceramic gear rollers. The second arc flashboard 2-2. And the inner walls of the inlet and outlet are equipped with ceramic lining or high wear-resistant organic matter.

[0037] Meanwhile, in the third embodiment, the main shafts and skeletons of the first and second ceramic gear rollers are made of metal materials, and the material contact parts are made of ceramic materials or organic wear-resistant materials. The skeletons of the first and second spindles are made of metal materials, and the material contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com