Guide pillar for bending steel bar mold

A technology of guide pillars and molds, which is applied in the direction of manufacturing tools, forming tools, metal processing equipment, etc., can solve the problems of high cost, ineffective reduction of guide pillar wear, complex structure, etc., and achieve low cost, simple structure, and reduced guide pillars. Possible effects of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

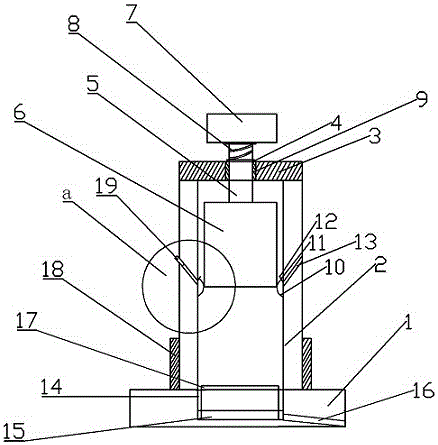

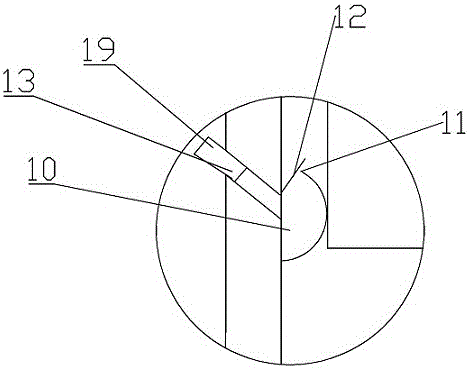

[0021] The reference signs in the drawings of the specification include: base 1, guide sleeve 2, end cap 3, guide hole 4, guide post A5, guide post B6, stopper 7, return spring 8, sealing washer 9, oil storage part 10 opening 11. Baffle plate 12, refueling pipe 13, oil guide channel 14, groove 15, oil delivery pipe 16, rubber pad 17, positioning sleeve 18, piston 19.

[0022] Such as figure 1 , figure 2 As shown, the guide post of the bending steel bar mold includes a base 1, a guide sleeve 2 threaded with the base 1 and a guide post, the guide post includes a guide post A5 and a guide post B6, the bottom end of the guide post A5 and the guide post The column B6 is detachably connected, the top of the guide sleeve 2 is equipped with an end cover 3, and the middle of the end cover 3 is provided with a guide hole 4, and the guide post A5 is installed in the guide hole 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com