Fully-automatic adjustable batch sample grinder

An adjustable, grinder technology, used in grinding devices, grinding machine tools, work carriers, etc., can solve the problems of inflexibility, the inability to automatically set and adjust the grinding time and force, and the inability to process large quantities of samples at the same time, so as to improve the grinding efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

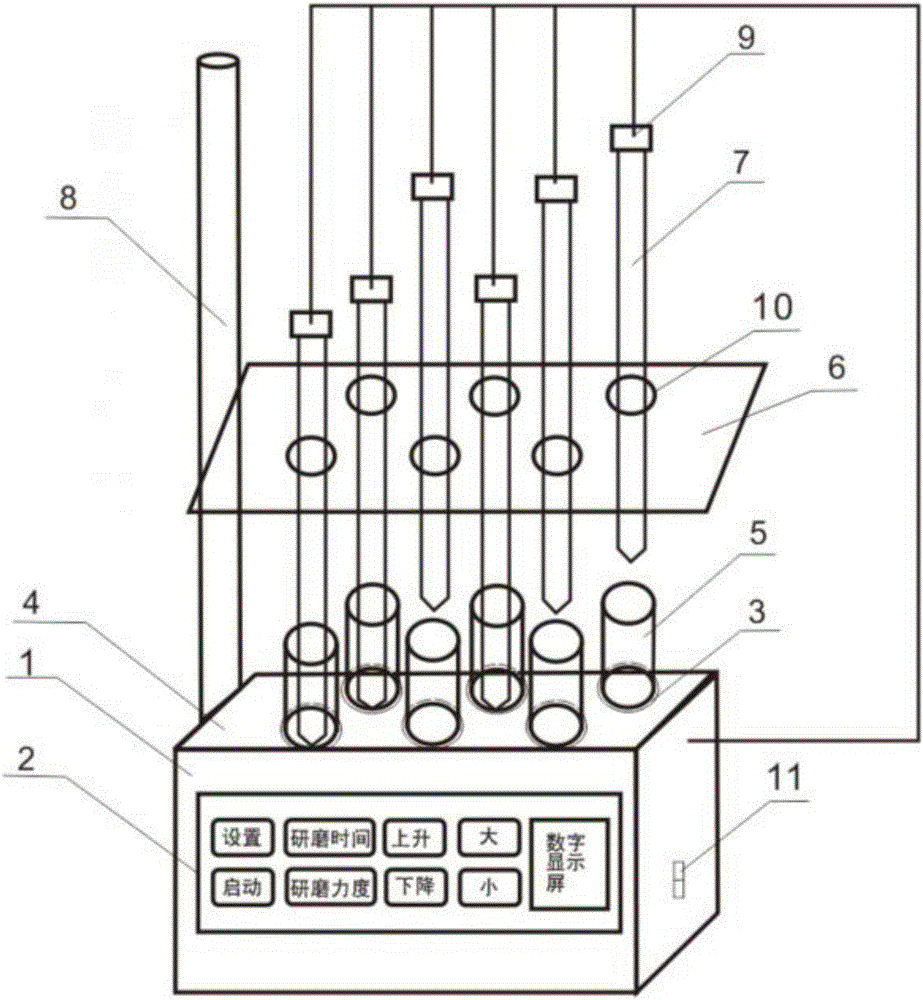

[0018] The present invention and its specific implementations will be described in further detail below in conjunction with the accompanying drawings.

[0019] see figure 1 , the present invention includes a base, a sample container, a support and a grinding pestle lifting platform, characterized in that:

[0020] A. One side of the base 1 is provided with an operation display screen 2, the other side is connected with the support 8, and the upper part is provided with a sample table 4 with a bayonet 3, and the sample container 5 is placed in the bayonet 3;

[0021] B. A grinding pestle 7 is installed on the grinding pestle lifting platform 6, one end of the grinding pestle is connected to the base 1 through a motor 9, the other end corresponds to the sample container 5, and one end of the grinding pestle lifting platform 6 is movably connected to the support 8 and Can move up and down along the bracket.

[0022] The bayonet socket 3 is a bayonet socket whose diameter can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com