A kind of elastic clamping mold for setting the shape of bamboo curtain box after gluing

A post-setting and bamboo curtain technology, which is applied in the manufacture of tools and wood processing equipment, etc., can solve the problems of lack of fastness, time-consuming, and low efficiency of the processing process between bamboo curtains and wood chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

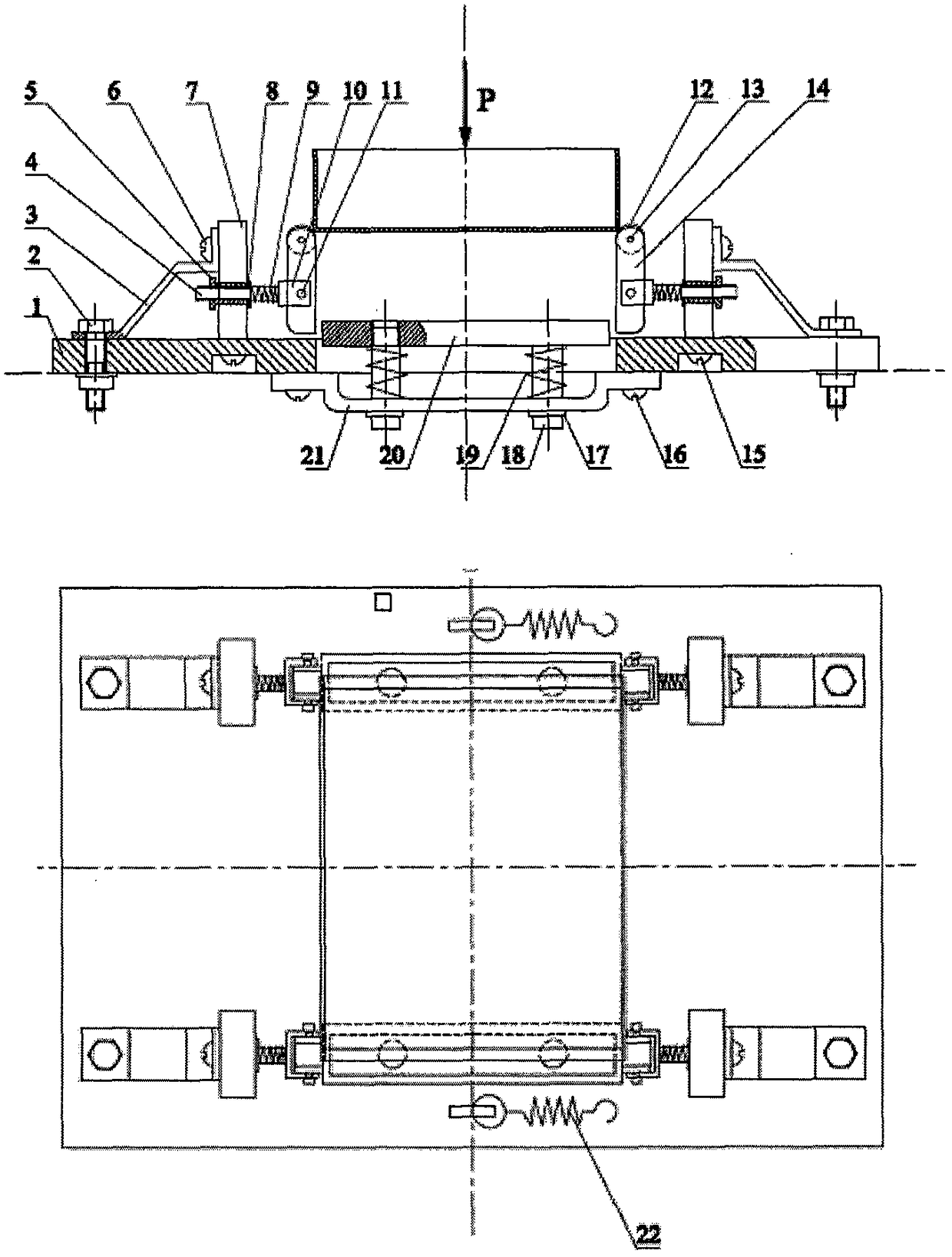

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail:

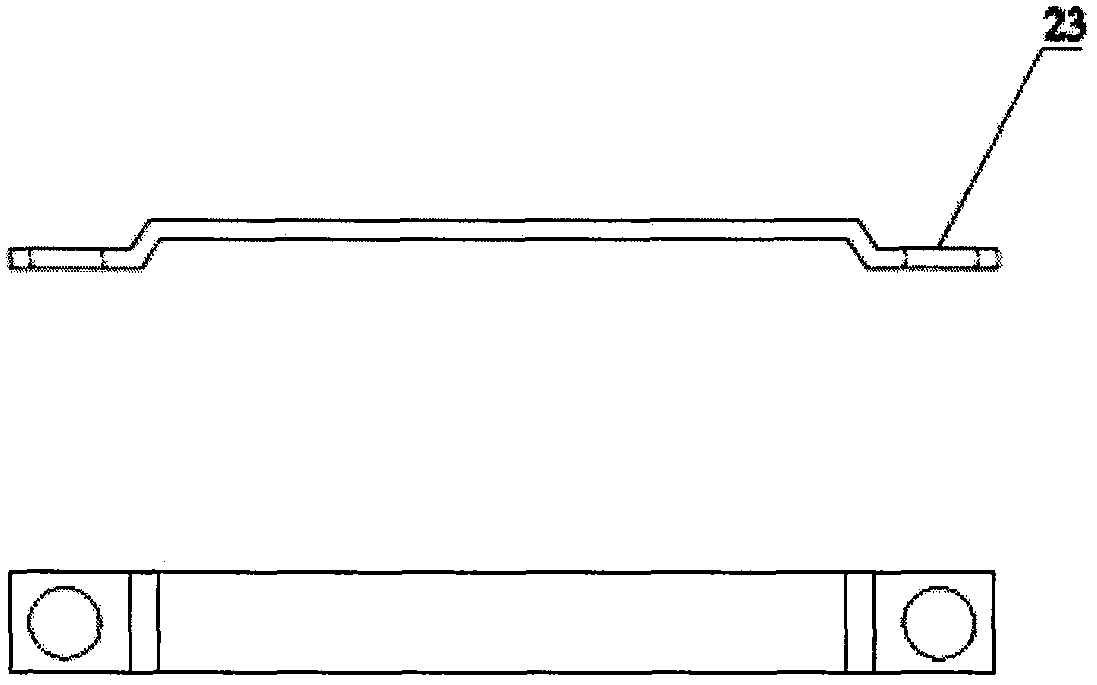

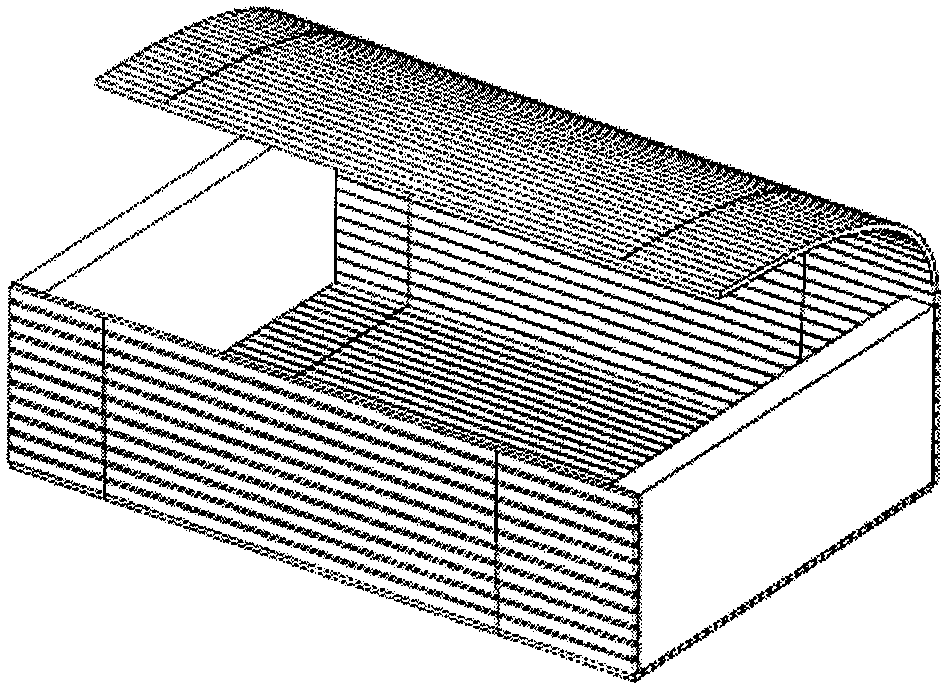

[0016] The elastic clamping mold for setting the shape of the bamboo curtain box after gluing is composed of the main base plate 1, four large back plate components, four pressure rod components, four pressure rod components, two limit block components and a longitudinal pressure component , the large backplane assembly is composed of fastening screws (2) under the bracket, fastening screws (6) on the bracket of the support frame (3), large backplane (7) and fastening screws (15) of the big backplane, and the pressure bar The assembly consists of a rear sliding rod (4), a nut sliding sleeve (5), a spring end gasket (8), a spring (9), a connecting yoke (10), a connecting yoke shaft (11), and a guide wheel (12) , shaft pin (13) and pressure rod (14), the limit block assembly consists of fastening screw (16), collar (17), guide rod (18), push spring (19), limit block ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com