A feeding tube for agricultural radish slices

A feeding tube and radish technology, applied in the agricultural field, can solve problems such as clogging and affecting the slicing work of the slicer, and achieve the effect of preventing radish accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

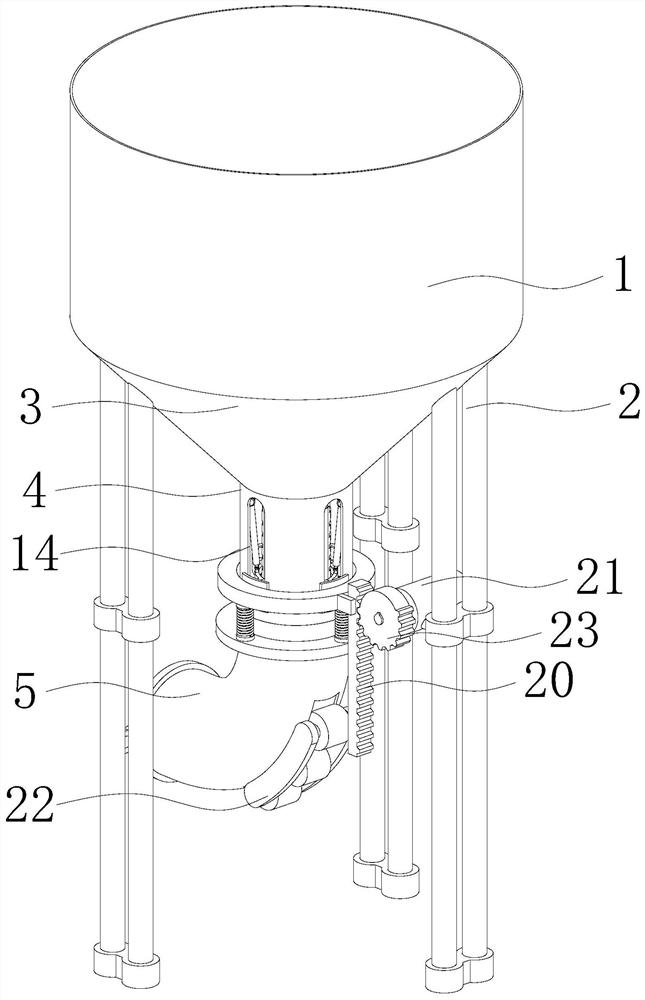

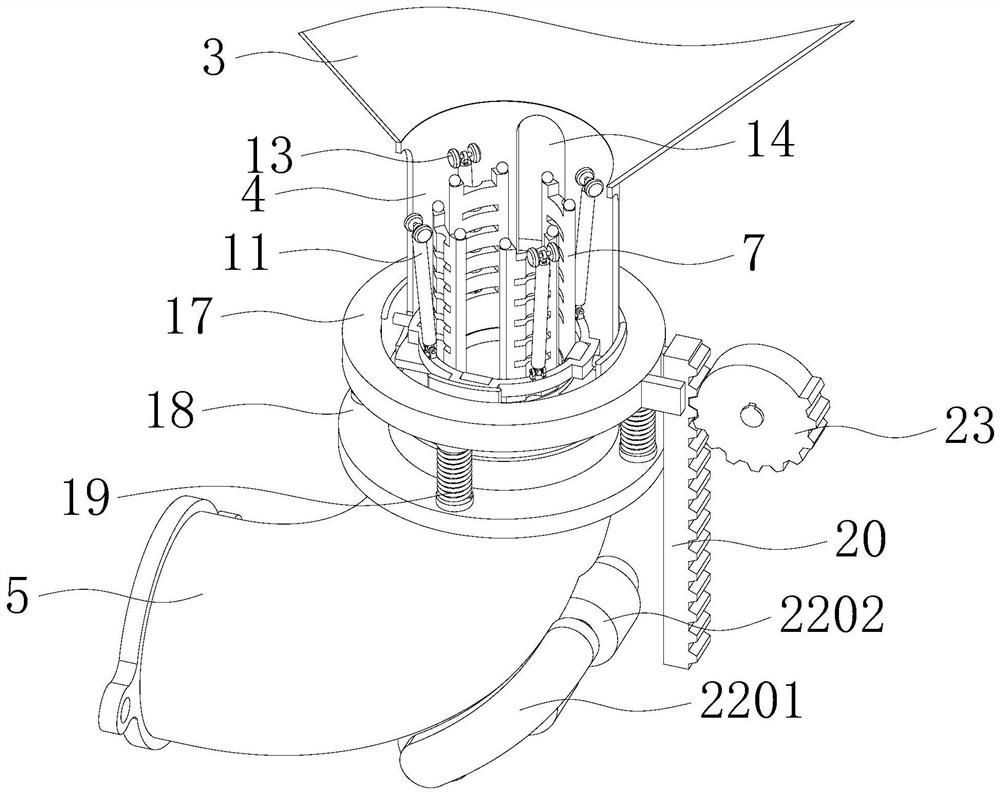

[0032] Such as Figure 1-8 As shown, a feeding tube for agricultural radish slices includes a delivery box 1 and three sets of brackets 2, the three sets of supports 2 are located below the delivery box 1, and the upper ends of the three sets of brackets 2 are all fixed to the bottom surface of the delivery box 1 Connect, three groups of supports 2 are equidistantly distributed with the axis line of the delivery box 1, and the angle between the two groups of supports 2 to the wheel is 90 degrees, and the supports 2 can be connected with some support devices in the prior art by bolts, The stability of the device can be improved. The bottom surface of the drop box 1 is fixedly connected with a tapered pipe 3, which can initially ensure the posture of the radish. The end of the tapered pipe 3 away from the drop box 1 is fixedly connected with an adjustment pipe 4. One end of the adjustment pipe 4 away from the tapered pipe 3 is fixedly connected with a guide elbow 5 .

[0033] T...

Embodiment 2

[0037] Such as Figure 5-8 As shown, the twist mechanism 12 includes two fixed plates 1201 and two torsion springs 1202, the bottom end of the guide rod 11 is located between the two fixed plates 1201, and the bottom end of the guide rod 11 is rotationally connected with the two fixed plates 1201, The torsion spring 1202 is located between the guide rod 11 and the fixed plate 1201 , and the two ends of the torsion spring 1202 are fixedly connected with the guide rod 11 and the fixed plate 1201 respectively, and both fixed plates 1201 are fixedly connected with the moving ring 9 .

Embodiment 3

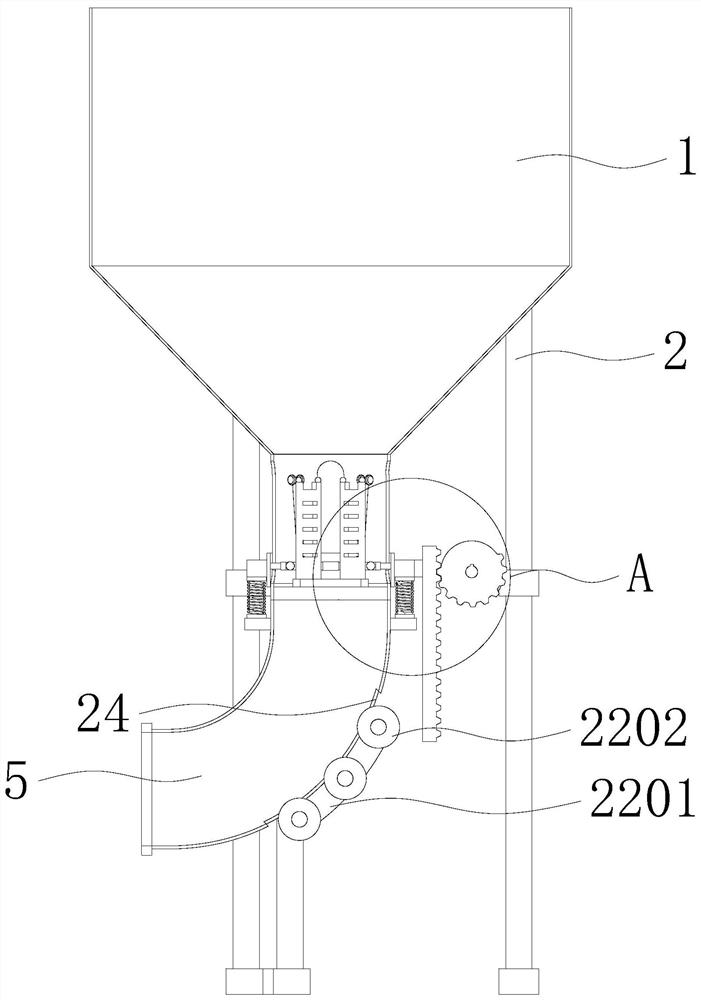

[0039] Such as Figure 2-3 As shown, the guide mechanism 22 includes two curved plates 2201 and three guide wheels 2202, and the three guide wheels 2202 are all located between the two curved plates 2201, and the front and rear surfaces of the three guide wheels 2202 are connected to the three curved plates 2201. Rotationally connected, the bottom surface of the guide elbow 5 is provided with a through groove 24, two bent plates 2201 are respectively located on the front and rear sides of the through groove 24 and are fixedly connected with the guide elbow 5, and one side of the three guide wheels 2202 runs through the through groove twenty four.

[0040] When in use, the radish can be placed inside the drop box 1, and the motor 21 is controlled to rotate. When the motor 21 rotates, the half gear 23 can engage the tooth plate 20 and then drive the tooth plate 20 to move upward. When the half gear 23 moves to the smooth side At this time, due to the pulling force of the four s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com