Back pressure type helical compression spring damper

A technology for compressing springs and dampers, which is used in protective buildings/shelters, building components, and shock-proofing. The effect of shock costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

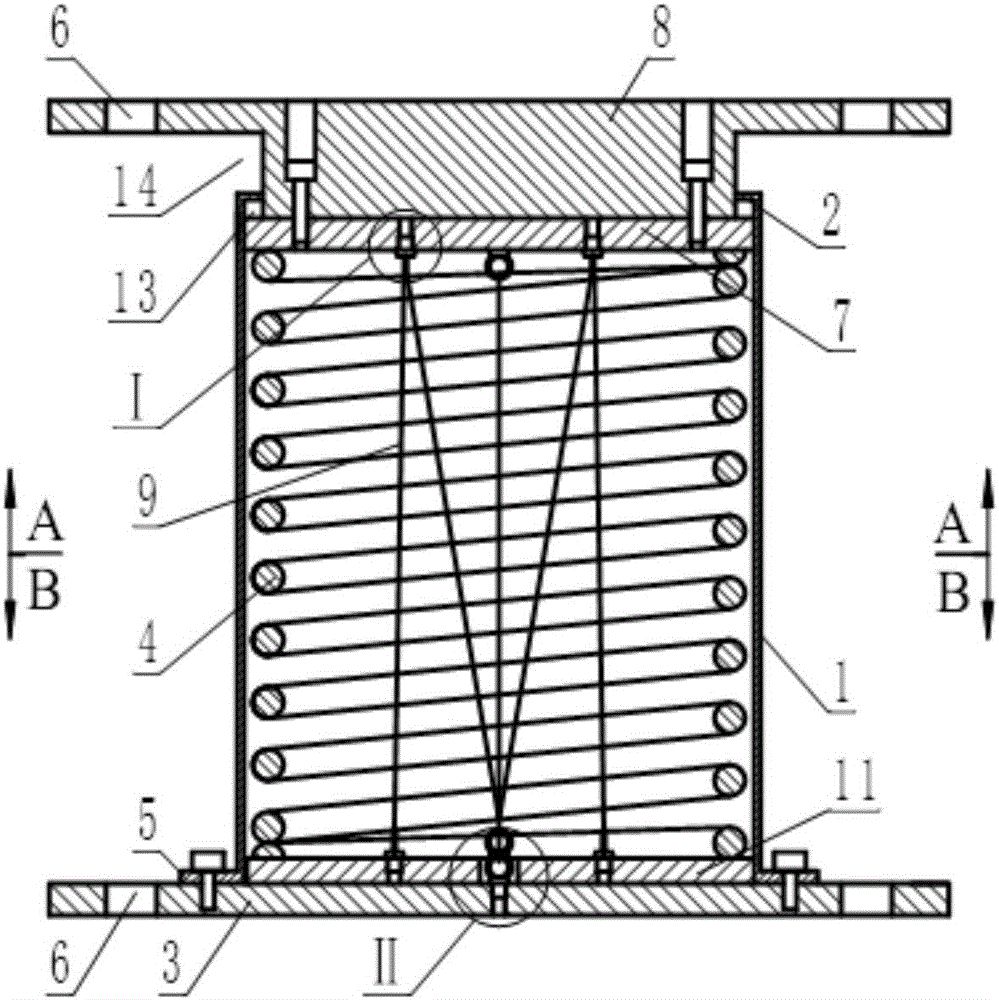

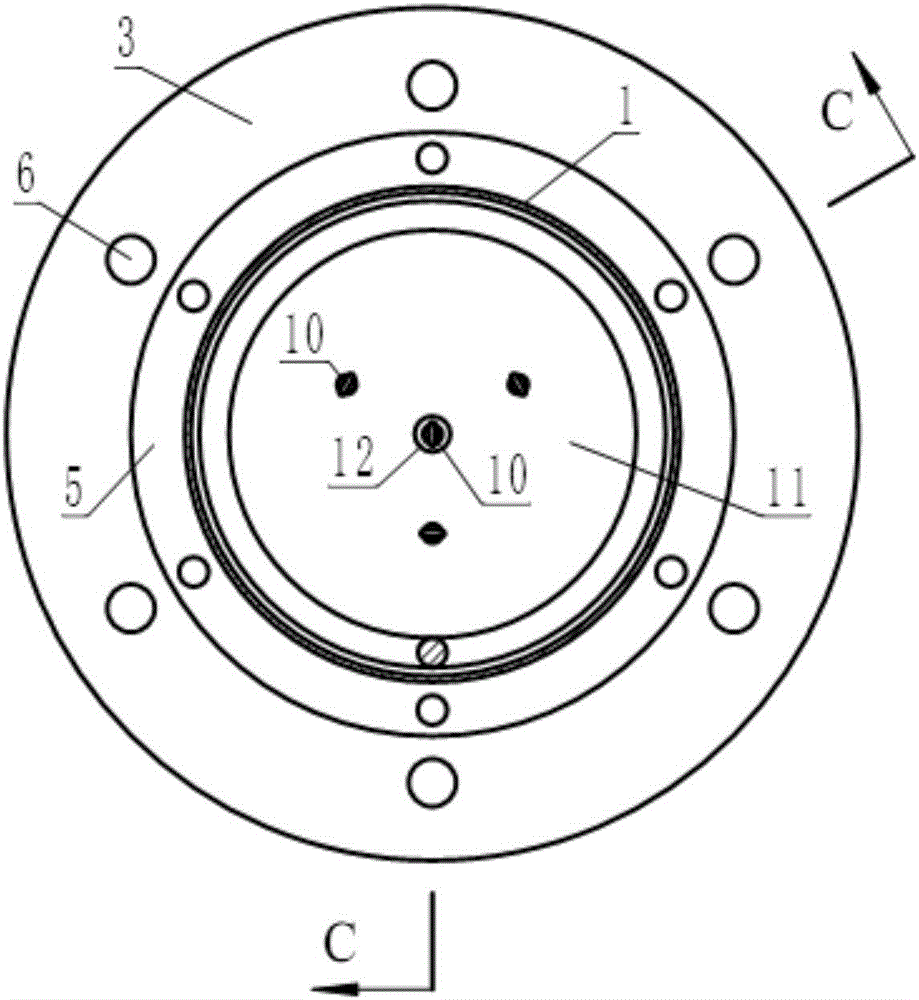

[0036] see Figure 1~5 , the damper described in this example is a vertical shock-isolation device (also known as a vertical shock-isolation support) for building anti-seismic, which includes a guide sleeve 1, a first end cover 2, a second end cover 3 , Cylindrical helical compression spring 4 and back pressure device.

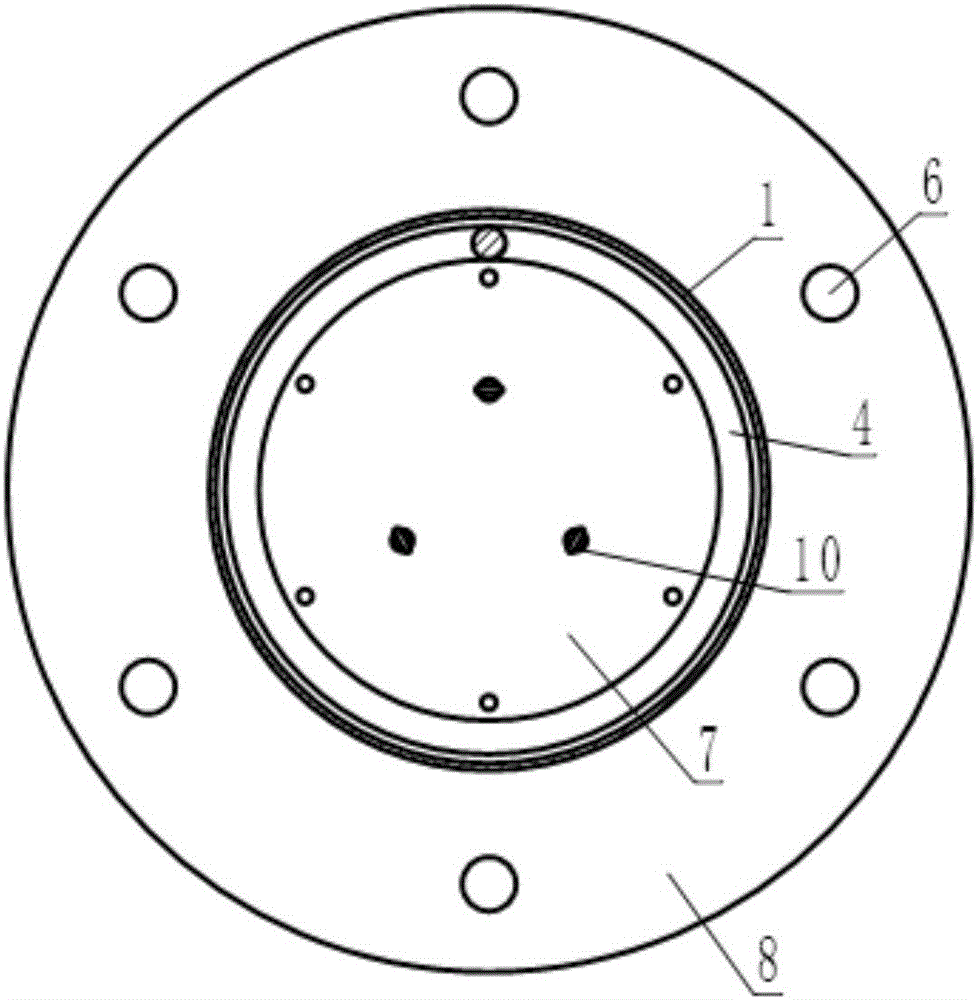

[0037] see Figure 1~3 , the guide sleeve 1 is in the shape of a circular tube, its upper end radially shrinks inward to form a first end cover 2 with a guide hole in the center, and its lower end radially extends outward to form a flange 5 . The second end cover 3 is disc-shaped, with installation holes 6 on the periphery, and the guide sleeve 1 is fixed in the middle of its upper surface by the flange 5 provided at the lower end.

[0038] see Figure 1~3 , the driving member is composed of a dynamic pressure plate 7 and an upper connecting plate 8, wherein the upper connecting plate 8 is disc-shaped, and the edge is provided with a mounting hole 6, and the...

example 2

[0050] see Figure 6-11 , the damper described in this example is also a vertical shock-isolation device for building anti-seismic, and on the basis of example 1, the following improvements are mainly made: (1) the pre-compressed steel wire rope 9 is increased by three to six; (2) replace the eye screw 10 as the wire rope changing element with a U-shaped member 15; (3) replace the eye screw 10 at the other end of the fixed preloaded wire rope 9 with a wire rope self-locking anchor 16; (4) The middle part of the second end cover 3 is thickened and uplifted to form an inverted washbasin shape, so as to install the wire rope self-locking anchorage 16; (5) correspondingly change the described back pressure device to:

[0051] The back pressure device consists of six preloaded steel wire ropes 9, six U-shaped members 15 as wire rope direction changing elements, a floating back pressure steel plate 11, six eyebolts 10 fixing one end of the preloaded steel wire ropes 9 and one fixed ...

example 3

[0060] see Figures 12 to 14 , this example is a damper used for seismic reinforcement of building structures, the damper includes a guide sleeve 1, the two ends of the guide sleeve 1 are respectively fixed with a first end cover 2 and a second end cover 3, and a cylindrical Helical compression spring 4, a driving member stretches into the guide sleeve 1 from the center of the first end cover 2 at one end of the guide sleeve and presses on the cylindrical helical compression spring 4; wherein the driving member is formed by the dynamic pressure plate 7 It is composed of a first driving rod 17 integrated with it, and the end of the first driving rod 17 is provided with a hinge hole 18 .

[0061] see Figure 12 The outer side of the second end cover 3 is symmetrically provided with two parallel lugs 19 integrally connected with it along the axis of the guide sleeve 1 , and the ends of the lugs 19 are also provided with hinged holes 18 .

[0062] see Figures 12 to 16 , the gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com