Smoke exhauster

A range hood and fan technology, which is applied in the field of kitchen appliances, can solve problems such as complex structure, low feasibility, and difficulty in integrating range hoods, and achieve the effect of improving smoking capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

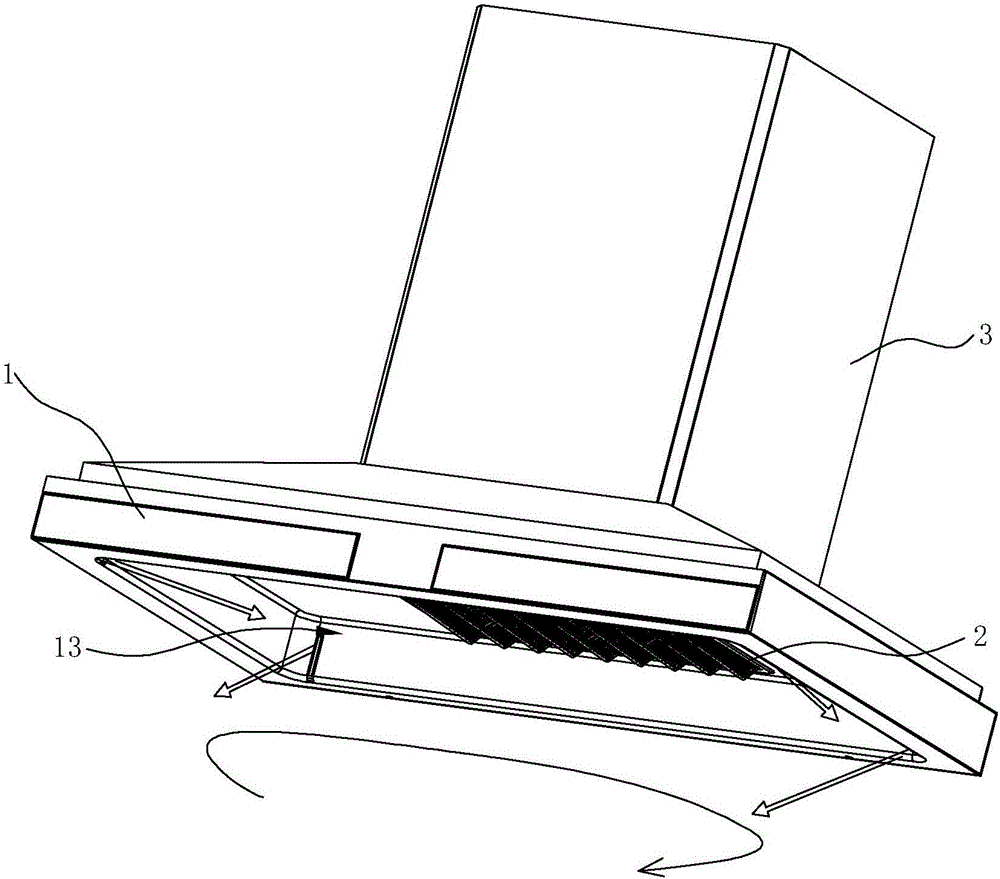

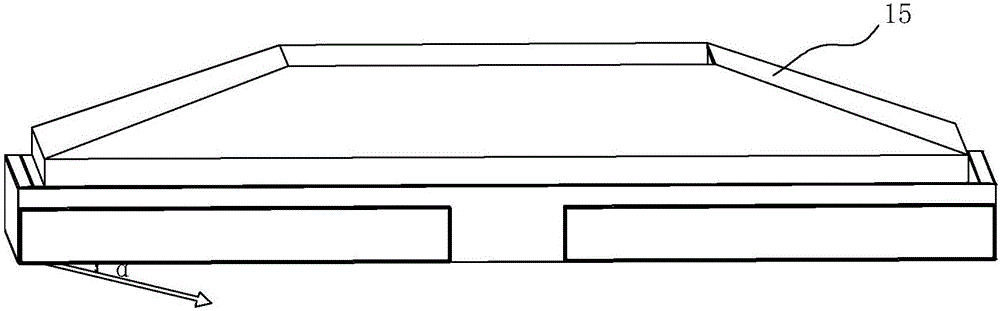

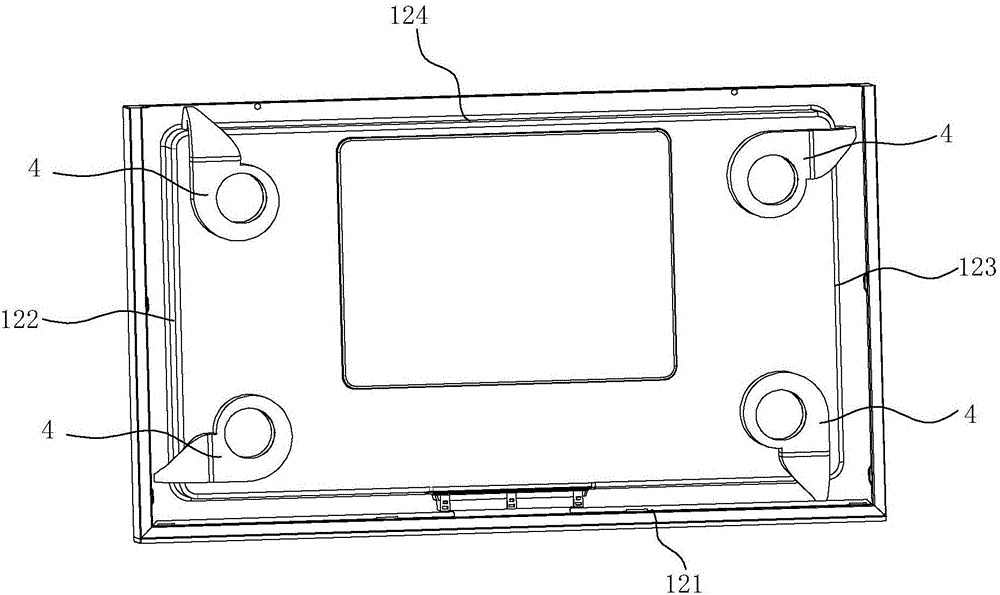

[0039] see Figure 2 ~ Figure 6 The smoke collecting hood 1 includes a top surface 11 and side surfaces, and the side surfaces include a front side 121, a left side 122, a right side 123 and a rear side 124. The smoke collecting hood 1 formed by the above five surfaces is concave to form a smoke collecting cavity 13. The bottoms of the above four sides extend outward to form a bottom surface, which corresponds to the side surfaces, including a front bottom surface 141, a left bottom surface 142, a right bottom surface 143 and a rear bottom surface 144. The bottom surface is turned upward at the outer edge, and a top plate is arranged above the fold 15. The top plate 15 is used to connect with the chassis 3.

[0040] In this embodiment, the air curtain device 4 is arranged at four corners on the top surface 11 . The air curtain device 4 includes a fan 41 and an air outlet device 42 , and the air outlet device 42 is formed with an air inlet 421 and an air outlet 422 . The blo...

Embodiment 2

[0044] see Figure 7 ~ Figure 9 , the difference from the first embodiment above is that in this embodiment, the air curtain device 4' includes a fan 41, an air outlet device 42, an air duct 43 and a drainage pipe 44, and an air inlet 421 is formed on the air outlet device 42 Along with the air outlet 422 , the air duct 43 is also formed with an air duct air inlet 431 and an air duct air outlet 432 . Fan 41 is connected with the air duct air inlet 431 of air duct 43, and the air duct air outlet 432 of air duct 43 is connected with one end of drainage pipe 44, and the other end of drainage pipe 44 is connected with the air inlet 421 of air outlet device 42, and drainage Tube 44 is preferably a rubber hose. The air outlet 422 of the air outlet device 42 is formed in a strip shape extending in the longitudinal direction, and each side of the smoke collecting hood 1 is provided with an air outlet hole 16 extending in the longitudinal direction at a position corresponding to the a...

Embodiment 3

[0047] see Figure 10 ~ Figure 12 , in this embodiment, only two air curtain devices 4 "are needed. Compared with the air curtain device 4' in Embodiment 2, the air curtain device 4 " is different in that the air outlet of the air curtain device 4 " There are two sets of devices 42 , air ducts 43 and drainage pipes 44 , and the two air ducts 43 are respectively connected to the two air outlets of the fan 41 , thereby forming a form of double-outlet fan rubber hose connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com