Extractor hood

A range hood and fan technology, which is applied in the field of kitchen appliances, can solve problems such as complex structure, low feasibility, and difficulty in integrating range hoods, and achieve the effect of improving smoking capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

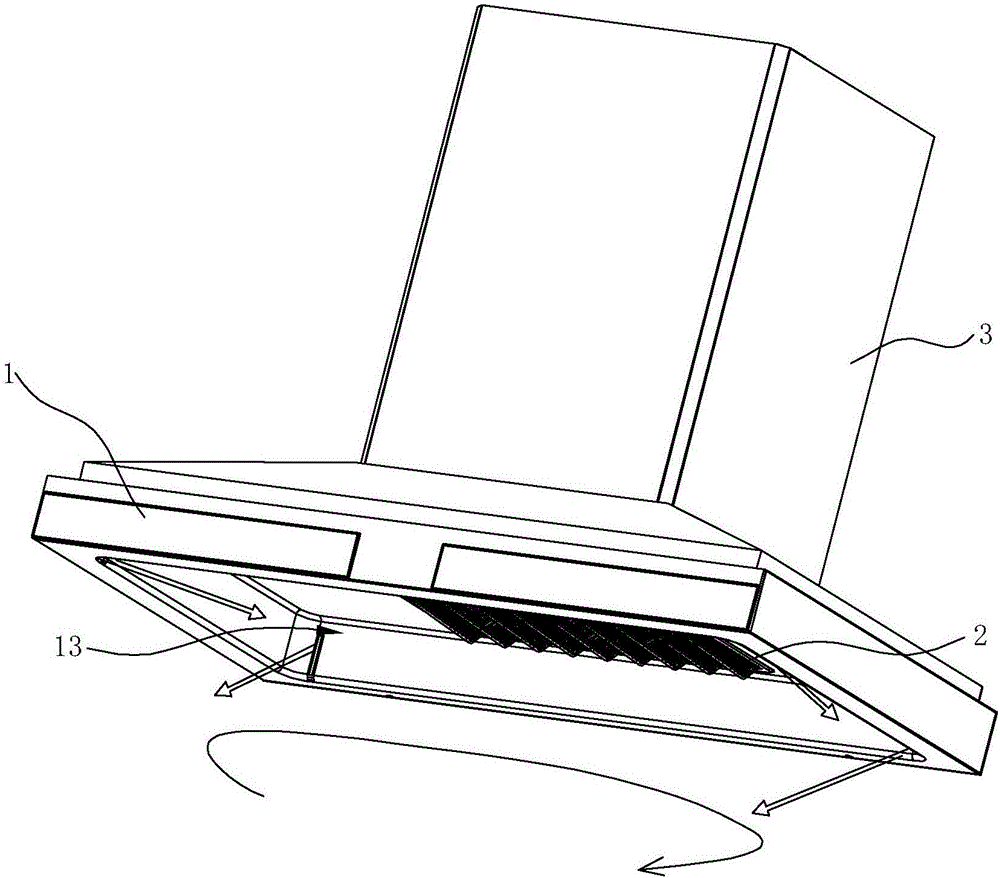

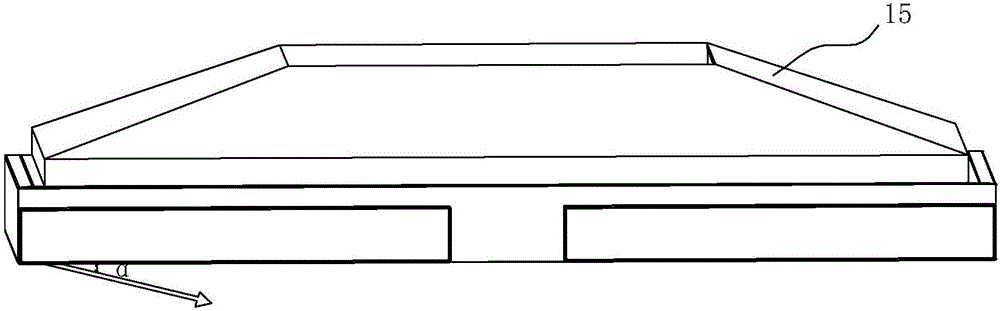

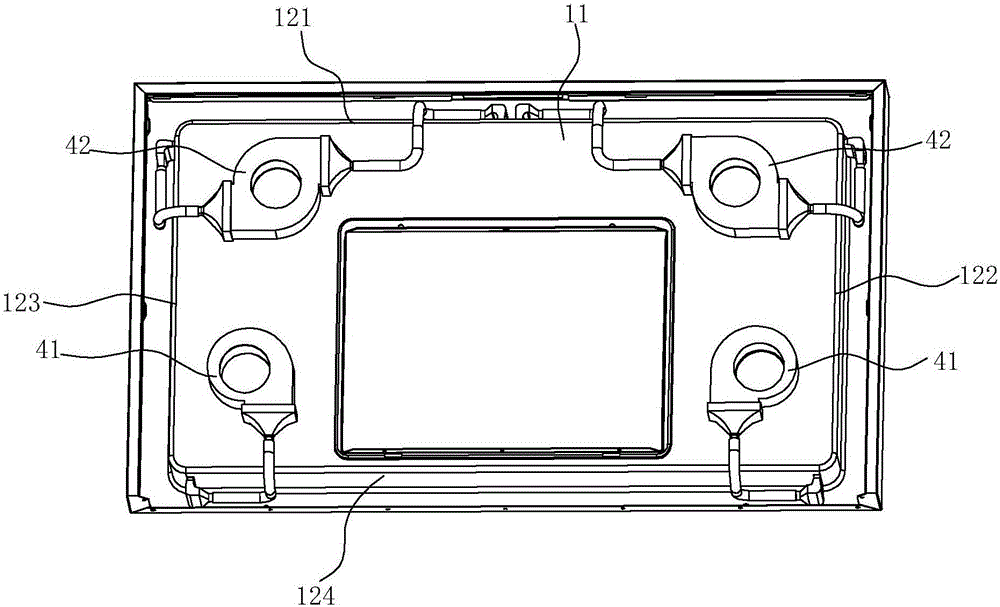

[0041] see Figure 2 ~ Figure 4 The smoke collecting hood 1 includes a top wall 11 and side walls, and the side walls include a front side wall 121 , a left side wall 122 , a right side wall 123 and a rear side wall 124 , and the above five walls together form a concave smoke collecting chamber 13 . The outer circumference of the bottom of the above four side walls extends outwards to form a bottom surface. The bottom surface and the side walls correspond to each other, including a front bottom surface 141, a left bottom surface 142, a right bottom surface 143 and a rear bottom surface 144. A top plate 15 is arranged above, and the top plate 15 is used for connecting with the chassis 3 .

[0042] The air curtain device comprises two first air curtain devices 41 and two second air curtain devices 42, the first air curtain devices 41 are located at two corners of the top wall 11 rear side respectively, and the second air curtain devices 42 are respectively located at the top Th...

Embodiment 2

[0049] see Image 6 , in this embodiment, the difference from the first embodiment above is that the angle α between the induced swirl flow and the horizontal direction or by setting a plurality of parallel arrangements in the first air outlet device 44 and the second air outlet device 44' achieved with longitudinally inclined partitions 442, Image 6 Take the second air outlet device 44' as an example. At this time, an air outlet hole 16 is formed on each bottom surface of the outer periphery of the bottom of the smoke collecting chamber 13, and the air outlet of the air curtain device and the air outlet hole 16 of the smoke collecting chamber 13 both extend in the transverse direction.

[0050] The air outlet method in this embodiment makes the air outlet position more outward, and the area of the swirling air curtain formed is larger than the inner air outlet method in the first embodiment above, which can further improve the effect of oil absorption.

Embodiment 3

[0052] see Figure 7 ~ Figure 9 The difference from the first embodiment above is that in this embodiment, the position of the air outlet hole 16 is a perforation, instead of the air outlet hole 16, which are respectively opened at the four corners of the bottom periphery of the smoke collecting chamber 13, and the front There are two in the middle of the bottom surface 141 (also two in the middle of the rear bottom surface 144). At this time, the position of the air outlet is at the bottom periphery of the smoke collecting chamber 13, and each air outlet device of the air curtain device can pass through the perforation Extend to below the fume collecting hood 1.

[0053] The second air outlet device 44' of the second air curtain device 42 is in the shape of a tube extending vertically. On the side wall of the device 44', and extending along the vertical direction. The first air outlet device 44 of the first air curtain device 41 has the same structure as the second air outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com