Deep seam strip mining and filling simulation test system and method

A simulation test system and coal seam technology, applied in the direction of fuel oil testing, material inspection products, preparation of test samples, etc., can solve the problems of lack of systematic basic research on the cracking law and crack evolution characteristics of the floor

Inactive Publication Date: 2017-02-15

SHANDONG UNIV OF SCI & TECH

View PDF6 Cites 26 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Many scholars at home and abroad have done a lot of research work on the evolution law of floor cracks in coal seam mining above confined water, and achieved a ser

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

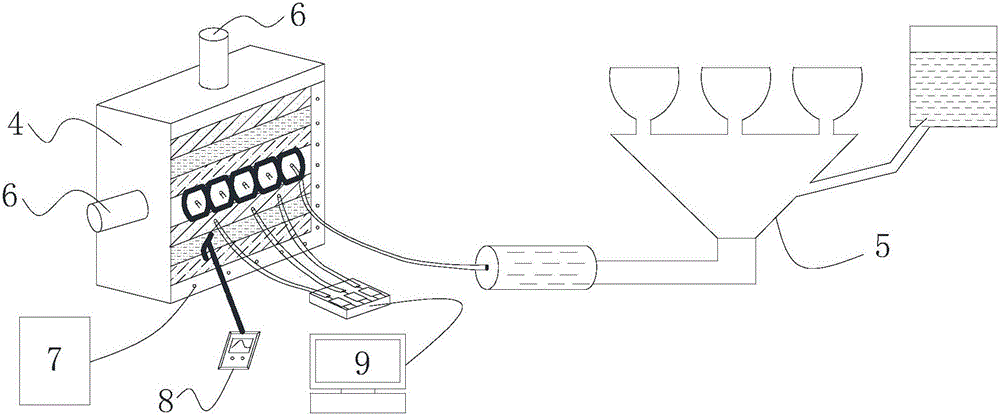

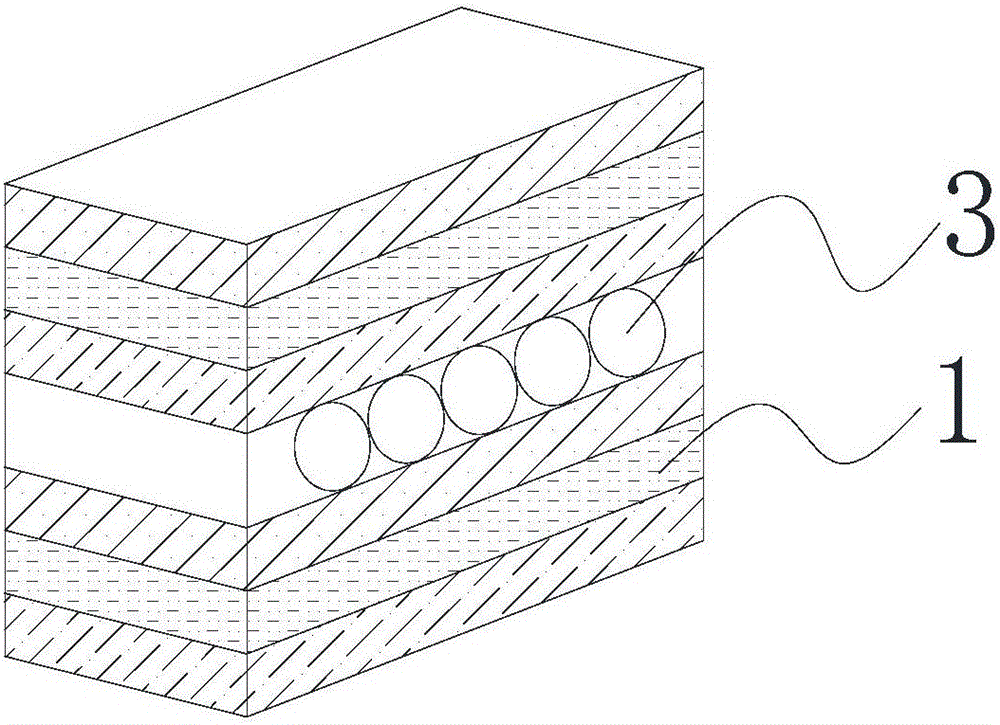

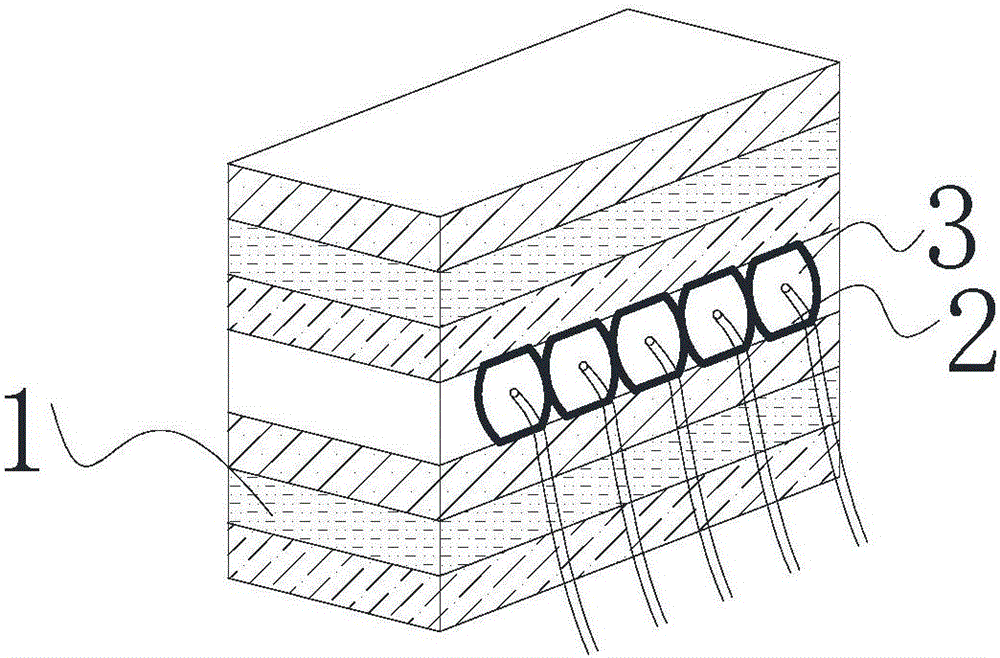

The invention discloses a deep seam strip mining and filling simulation test system and method, relates to the field of preventing and treating deep rock fissure evolution and water inrush, and solves the important problem that the prior fundamental research is relatively insufficient on rock fracturing law of deep coal seam mining on high confined water, fissure evolution characteristics and inrush prevention by filling; the test system comprises a bearing box, a test model and a filling system; the test model is positioned in the bearing box and comprises a rock stratum and a coal seam positioned in the rock stratum, the rock stratum is made by laying similar material, a water confining device is arranged around the rock stratum, a plurality of sensors and a plurality of plastic balls loaded with calcium oxide particles are buried in the rock stratum, and the coal seam is simulated by arranging a plurality of loaded air bags. The test system can simulate the mining of coal seams under different ratios of extraction to reservation and different mining thickness, and can also provide the study on stress and displacement change law of roof and floor after the mining of coal seams under ratios of extraction to reservation and different mining thickness and after filling of a gob.

Description

technical field [0001] The invention relates to the evolution of deep rock mass fissures and the prevention and control of water inrush disasters, in particular to a deep coal seam strip mining and filling simulation test system and a simulation test method. Background technique [0002] The evolution of fissures in the deep floor rock mass and hydraulic coupling are the essential causes of water inrush at the working face. Studying the evolution law of deep floor rock mass rupture and fissures has scientific guiding significance for the safe mining of coal seams above confined water and the evaluation of water inrush disasters. The statistics of water inrush in existing mining areas show that more than 80% of water inrush events are related to fault structures, and water inrush rarely occurs under the condition of a complete floor. High ground stress, mining disturbance and high confined water are more likely to lead to the activation of floor faults, resulting in rock mas...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N33/22G01N1/28G01N15/08

CPCG01N33/222G01N1/28G01N15/08G01N2015/0813

Inventor 陈军涛尹立明陈明路畅李金平张士川赵金海张保良张呈祥

Owner SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com