Leak detection device for underground diaphragm wall and construction method of leak detection device

A technology of underground diaphragm wall and detection device, which is applied in basic structure engineering, basic structure testing, construction, etc., can solve problems such as the constant existence of safety risks in foundation pit excavation, hidden leakage risks, etc., to improve leakage monitoring efficiency, The effect of reducing space usage and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

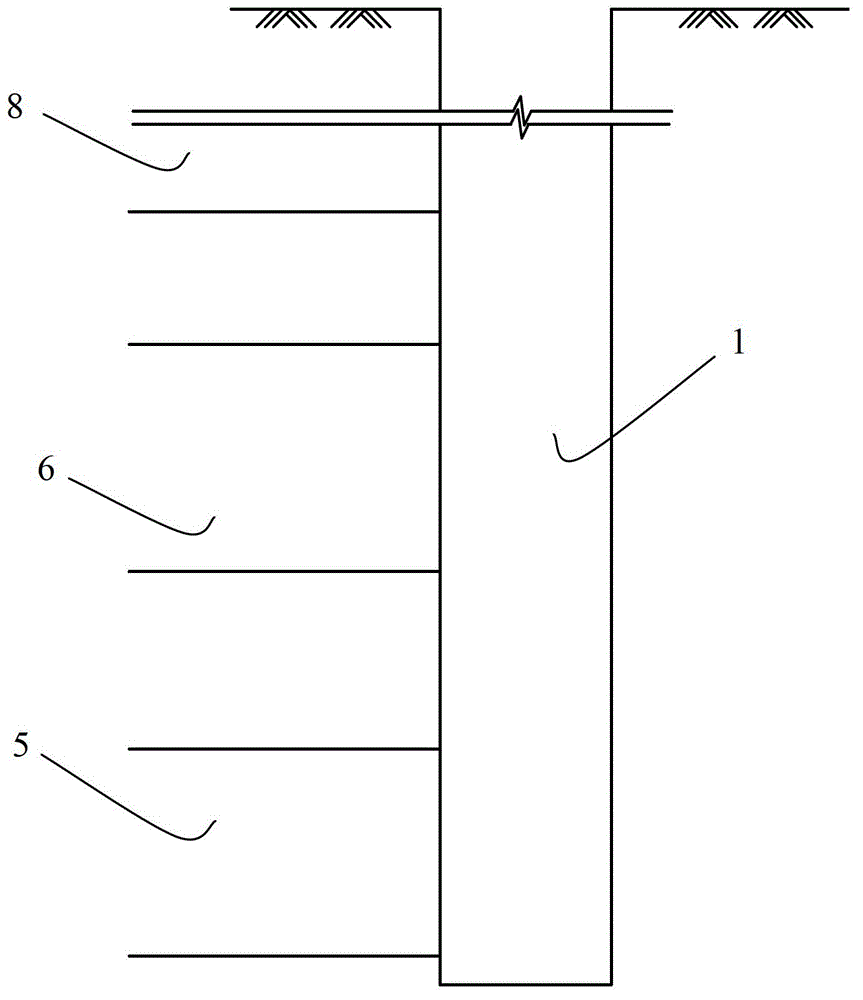

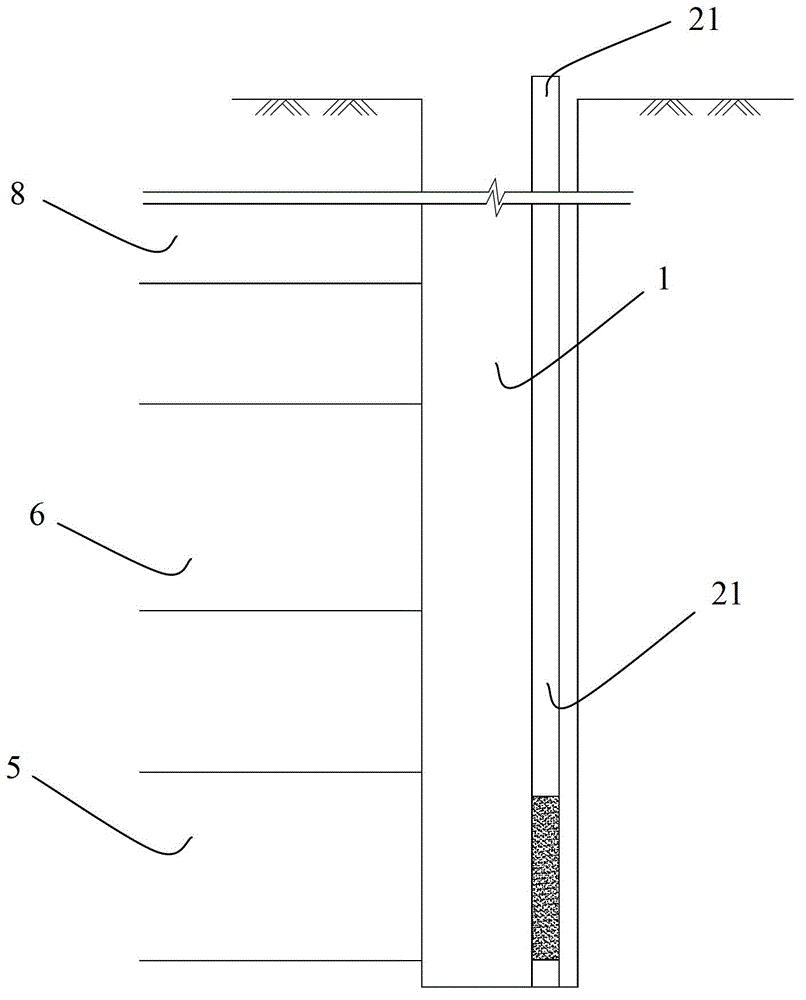

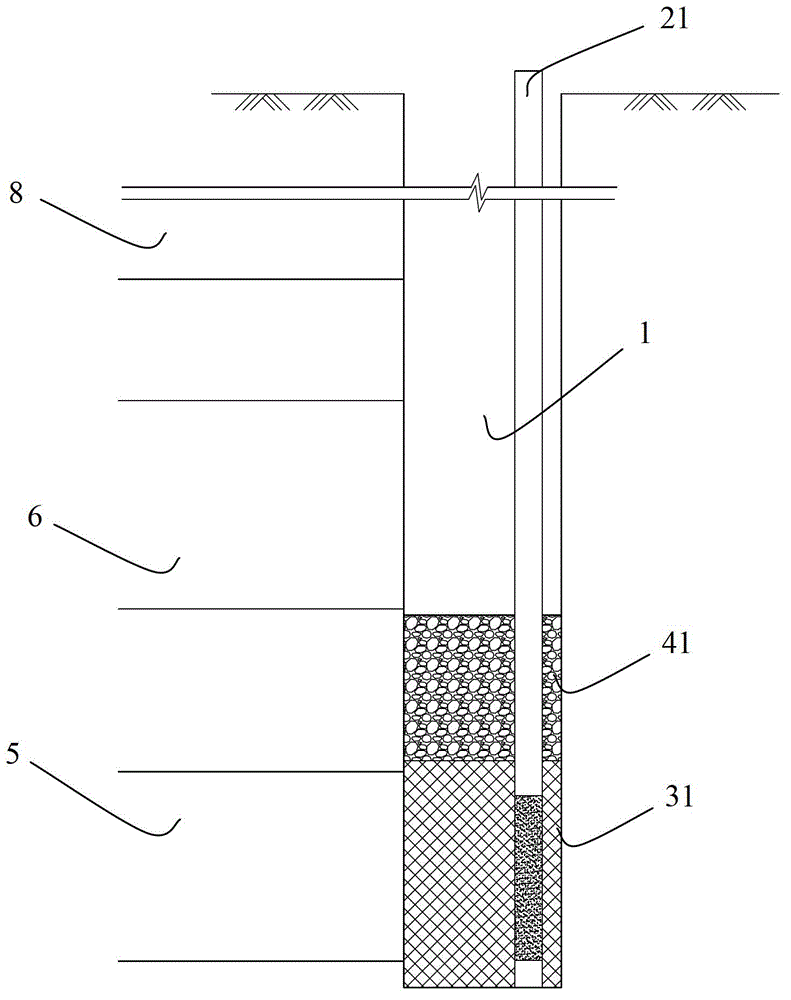

[0024] In order to facilitate the understanding of the structure of the present invention, the following description will be made in conjunction with the accompanying drawings and embodiments.

[0025] to combine Figure 7 As shown, the underground diaphragm wall leakage detection device of the present invention takes monitoring one layer of shallow water layer and two layers of confined water layer as an example. Figure 9 As shown, the distance between the monitoring well and the joint 10 of the underground diaphragm wall 9 is 1m to 3m. Three PVC pipes with a diameter of 110 mm and a wall thickness of 2.5 mm are arranged in the well hole 1 of the monitoring well as well pipes 2, and the well pipes 2 are connected by pipe clamps. The bottom ends of each well pipe 2 are provided with a plurality of through holes 7 Such as Figure 8 As shown, the opening range of the through hole 7 is the thickness of the shallow water layer and the confined water layer where the well pipe 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com