Automatic egg picking and loading device

An automatic and egg-loading technology, which is applied in the application, poultry industry, poultry cages or houses, etc., can solve the problems that the egg picking equipment does not have multi-level buffers, the structure of egg claws is not very reasonable, and the output cannot be measured. The effect of saving the time of packing eggs, increasing the speed of collection and packing, and reducing the working steps and workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

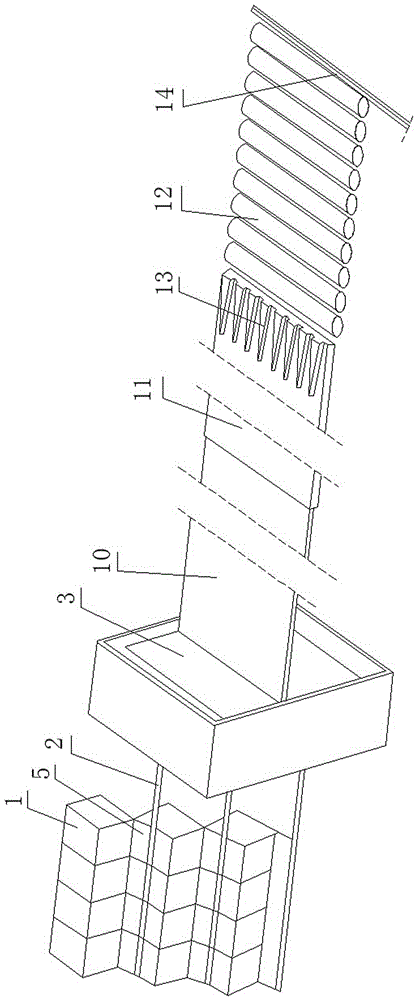

[0030] An automatic egg picking and loading device, which consists of: a chicken cage 1 and a conveyor belt. The chicken cage 1 is connected to an egg collection device 3 through a conveyor belt I2, and a cylindrical conveyor belt 12 is arranged at the lower end of the egg collection device 3. The lower end of the cylindrical conveyor belt 12 is an egg separation parallel device, and a counter 4 is arranged on the egg separation parallel device, and an egg tray is arranged at the lower end of the egg separation parallel device.

Embodiment 2

[0032] In the automatic egg picking and loading device described in Example 1, the bottom end of the chicken cage 1 is provided with an inclined plate 5, the inclined plate 5 forms an acute angle with the horizontal, and the lower end of the inclined plate 5 is provided with a conveyor belt I2. One end, the other end of the conveyor belt I2 is provided with an egg collecting device 3 .

Embodiment 3

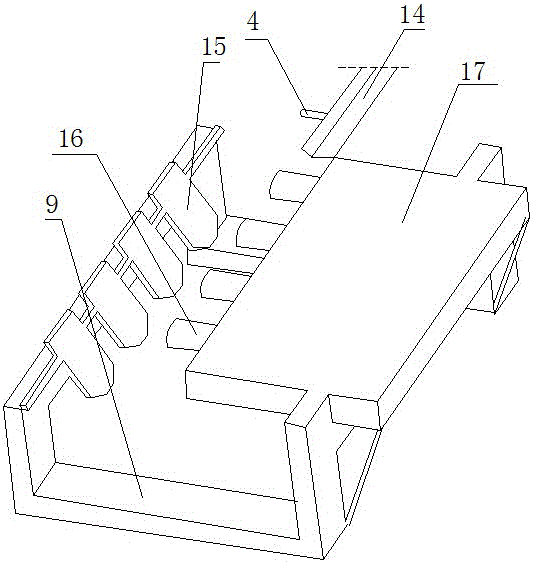

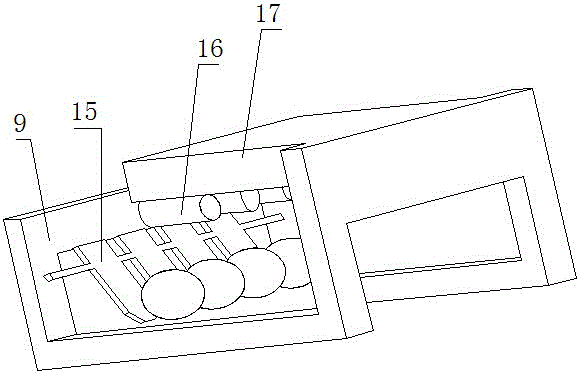

[0034] In the automatic egg picking and egg loading device described in Embodiment 1, the egg collecting device 3 includes egg claws 6, and the egg claws 6 are arranged at intervals on the soft conveyor belt 7, and the soft conveyor belt 7 surrounds two The pulleys 8 rotate, one of the pulleys 8 is controlled by a motor, and the egg claws 6 are herringbone-shaped, each of the egg claws 6 is arranged at intervals, and one side of an egg claw 6 is connected to the adjacent egg claw. The other side of 6 forms a semicircle, one end of the buffer table 10 is set on one side of the egg claw 6, and a connecting plate 11 is set on the other end of the buffer table 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com