Water spraying type window wiper

A technology of window scraping and water spray nozzle, applied in the field of water spraying window scraping, can solve the problems such as inability to adjust the angle of the window scraper, poor practicability, etc., and achieve the effect of strong practicability, reasonable design and improved cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

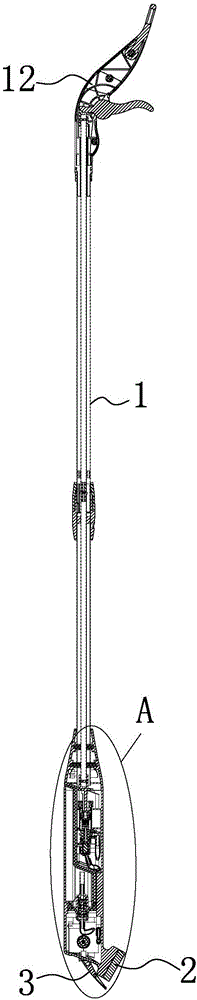

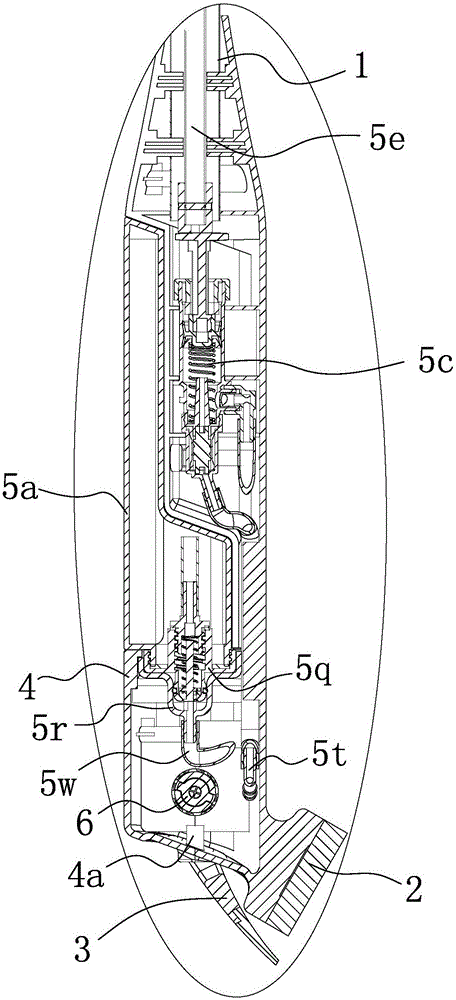

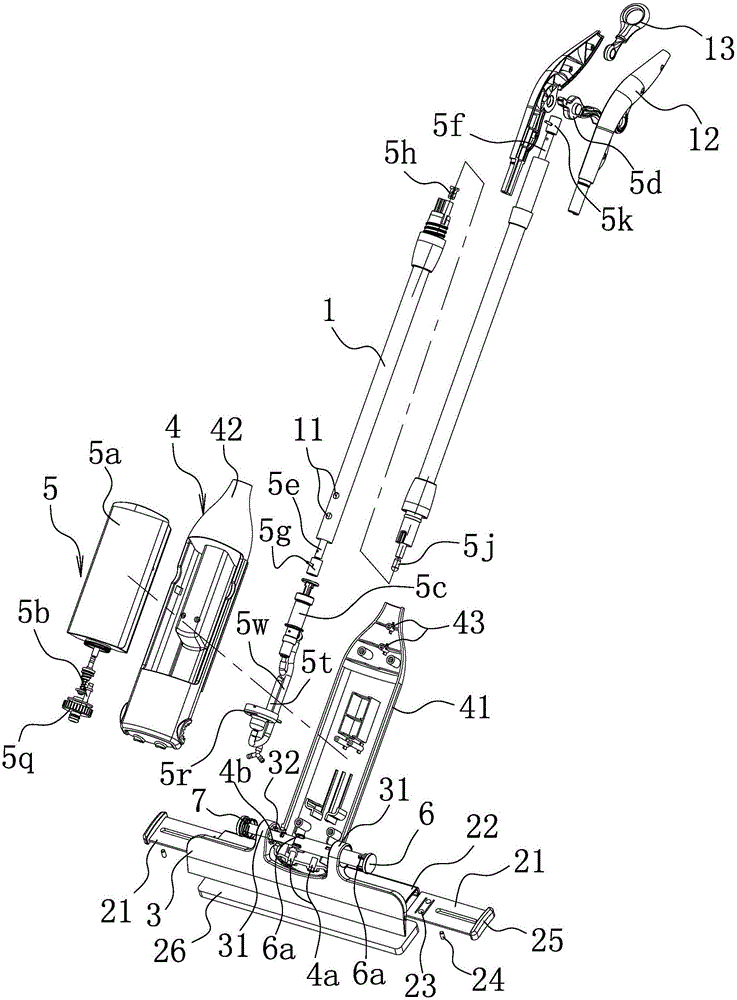

[0036] like figure 1 and image 3 As shown, the water spray window scraper includes a holding pipe 1, and the holding pipe 1 includes a front pipe and a rear pipe connected to the rear end of the front pipe, and the front pipe and the rear pipe are connected and fixed by a connecting joint. The front pipe and the rear pipe are each made of plastic pipe.

[0037] like Figure 2-3 As shown, a cleaning head 2 and a scraper 3 are connected to the front end of the holding pipe 1. The cleaning head 2 includes two telescopic end plates 21 and a panel 22 with a chute. Insert and the caliber of the notch of the chute is smaller than the width of the telescopic end plate 21, and an outer limit structure for preventing the telescopic end plate 21 from leaving the chute outward is provided between the panel 22 and the telescopic end plate 21. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com