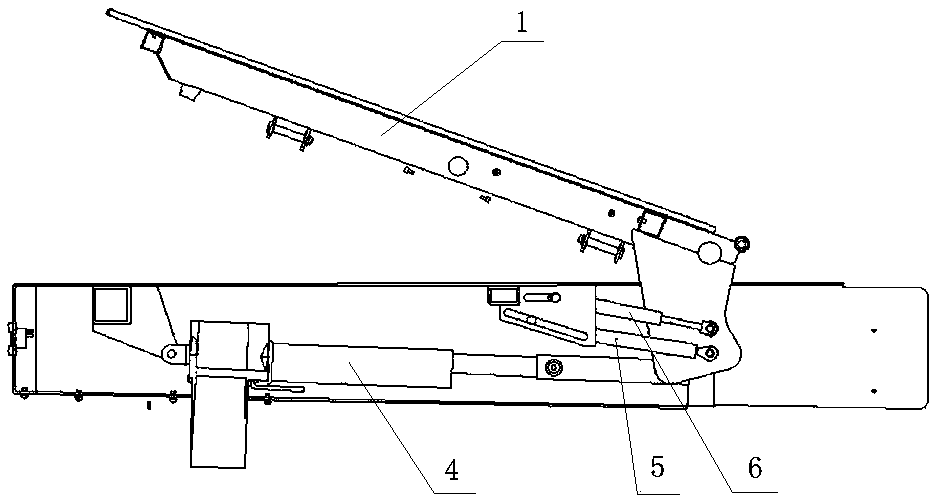

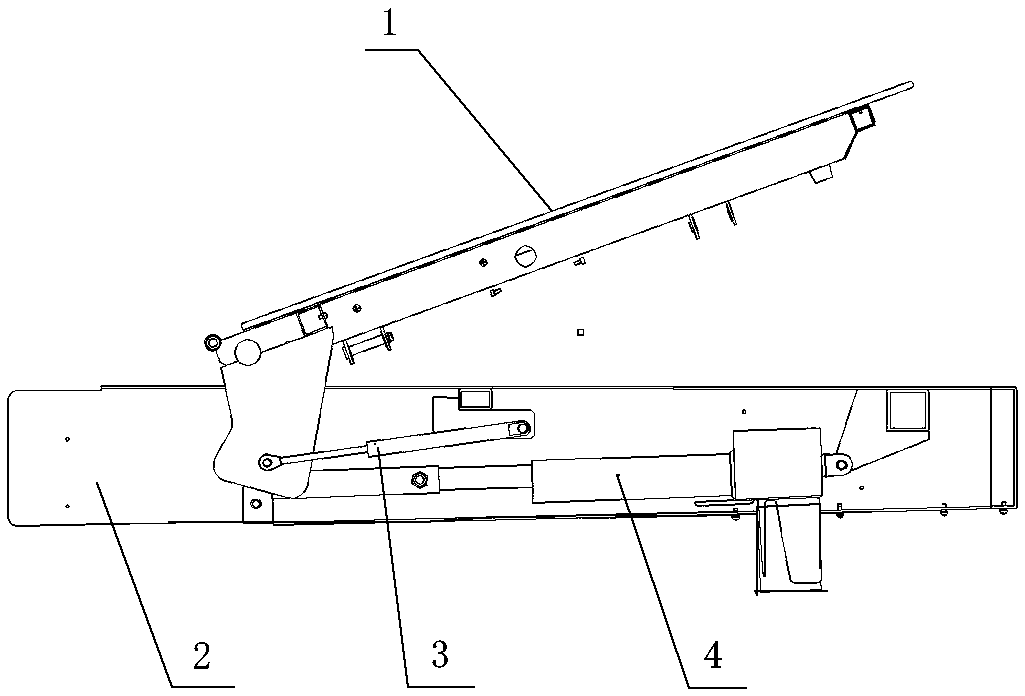

Speed-controllable backboard release device for obstetric bed

A release device and backboard technology, applied in the field of medical devices, can solve the problems of long order cycle, poor control of backplane descending speed, high price, etc., to achieve stable release speed, overcome changing load, and strong resistance to load The effect of the ability to change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

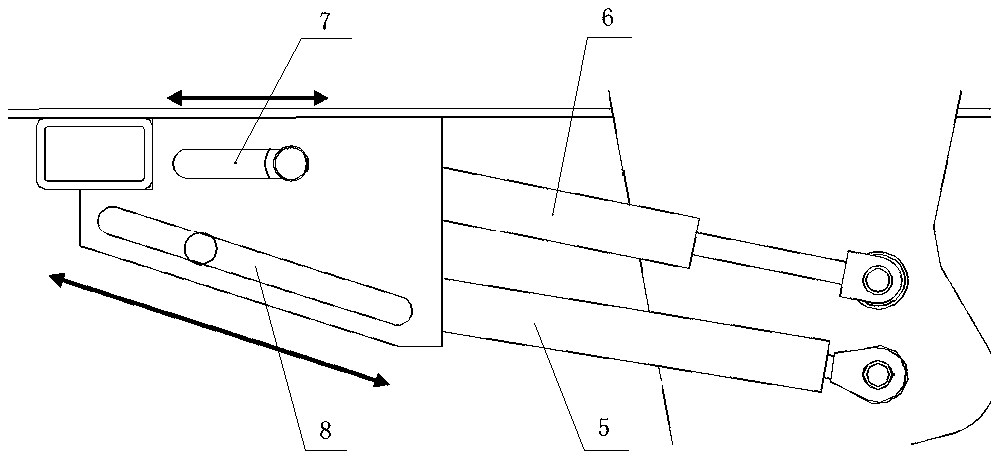

[0022] The weight of backplane 1 is 5KG, the load of backplane 1 is 35KG, the damping value of upper gas spring 6 is 250N, the damping value of lower gas spring 5 is 250N, the damping value of damping rod 3 is 480N, and the maximum backplane rotation angle is 65°;

[0023] When adjusting the backplane 1 to the maximum backplane angle, the cylindrical rollers of the sliding structure hinged with the upper gas spring 6 and the lower gas spring 5 are respectively in contact with the starting points of the upper chute 7 and the lower chute 8, and the upper gas spring 6 and the lower gas spring 5 is the shortest length. When the backboard 1 falls from the maximum backboard rotation angle to an angle of 48° with the horizontal plane, the cylindrical roller of the sliding structure hinged with the upper gas spring 6 contacts the end point of the upper chute 7, and the upper gas spring 6 starts At this time, when the backboard 1 falls from an angle of 48° to the horizontal plane to an ...

specific Embodiment 2

[0025] The weight of backplane 1 is 5KG, the load of backplane 1 is 35KG, the damping value of upper gas spring 6 is 250N, the damping value of lower gas spring 5 is 250N, the damping value of damping rod 3 is 480N, and the maximum backplane rotation angle is 65°;

[0026] When adjusting the backplane 1 to the maximum backplane angle, the cylindrical rollers of the sliding structure hinged with the upper gas spring 6 and the lower gas spring 5 are respectively in contact with the starting points of the upper chute 7 and the lower chute 8, and the upper gas spring 6 and the lower gas spring 5 is the shortest length. When the backboard 1 falls from the maximum backboard rotation angle to an angle of 42° with the horizontal plane, the cylindrical roller of the sliding structure hinged with the upper gas spring 6 contacts the end point of the upper chute 7, and the upper gas spring 6 starts At this time, when the backboard 1 falls from an angle of 42° to the horizontal plane to an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com