Ultra-fine dry powder nozzle with adjustable spray angle

A spray angle, ultra-fine dry powder technology, applied in fire rescue and other directions, can solve the problems of slow fire extinguishing speed, poor fire extinguishing effect, direct spray coverage can not be adjusted, etc., to achieve the effect of improving fire extinguishing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

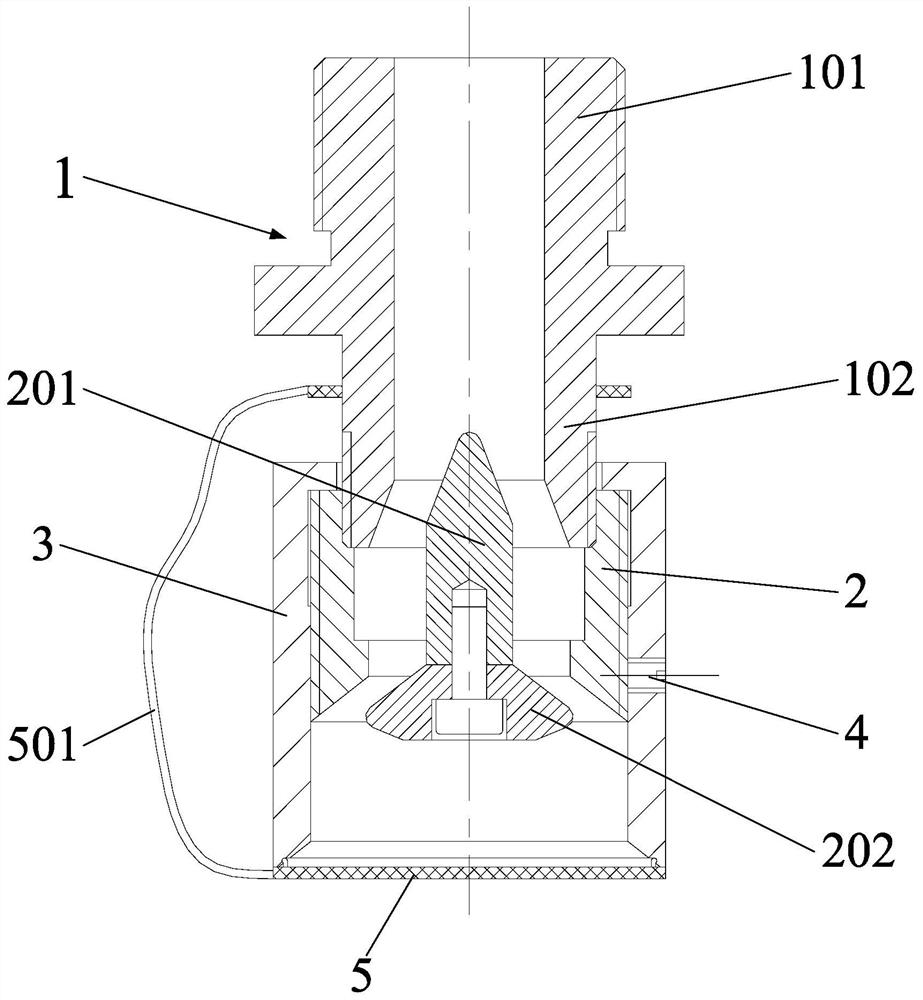

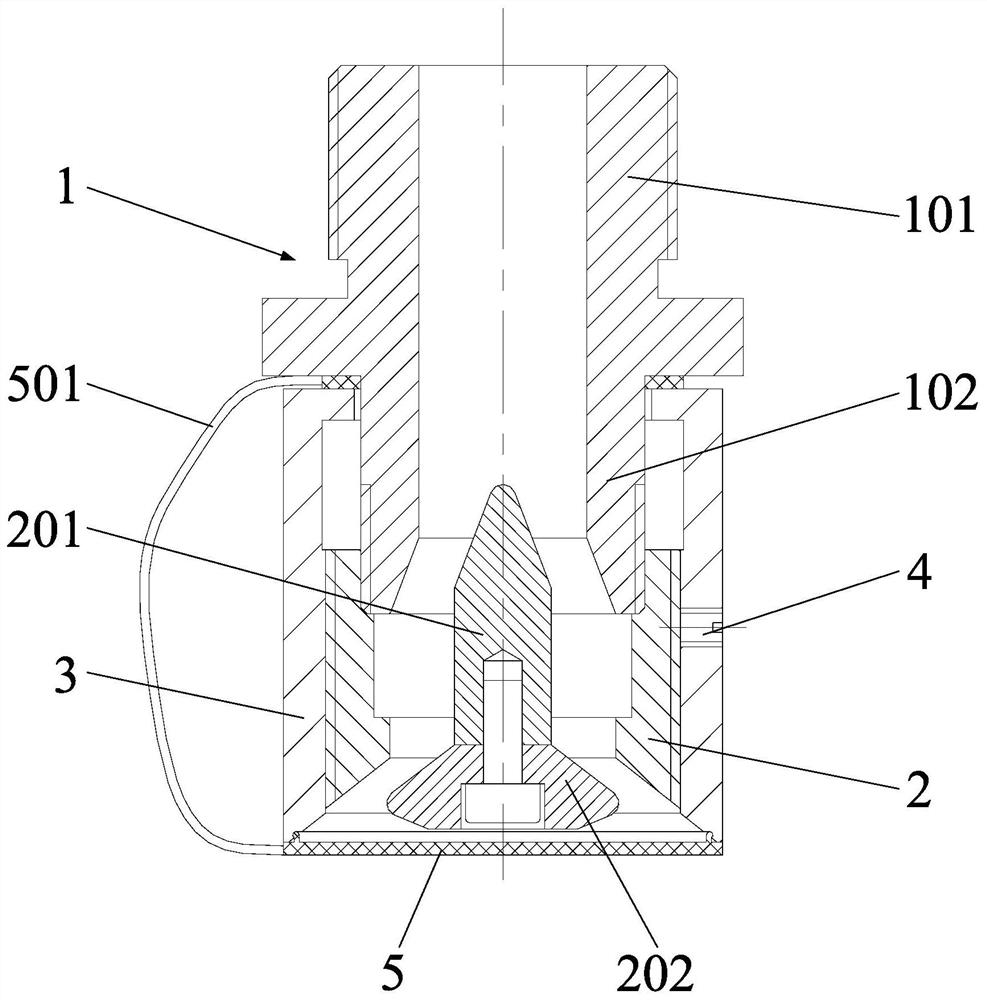

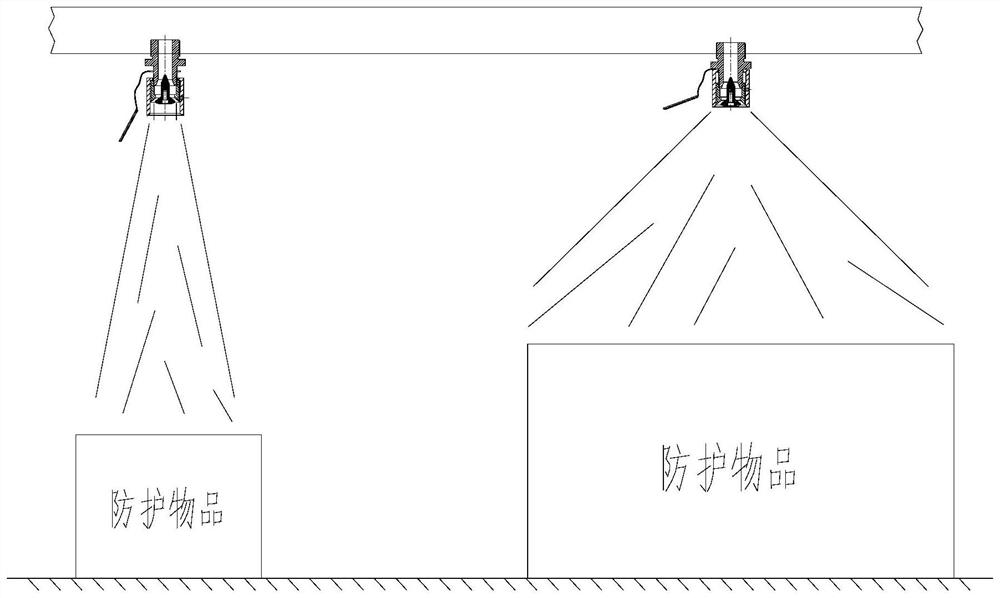

[0027] refer to Figure 1 to Figure 3 According to an embodiment of the present invention, an ultra-fine dry powder spray head with adjustable spray angle is proposed, including a connecting seat 1, and the connecting seat 1 is provided with a collecting pipe joint and a nozzle joint, and a fire nozzle is connected to the nozzle joint 2. The outer side of the fire nozzle 2 is provided with a sliding sleeve 3, and a locking device is provided between the sliding sleeve 3 and the fire nozzle 2.

[0028] In the above embodiments, the sliding sleeve 3 is set on the outside of the fire nozzle 2, and the ultrafine dry powder sprayed by the fire nozzle 2 will be sprayed through the port of the sliding sleeve 3, and the closer the port of the sliding sleeve 3 is to the injection port of the fire nozzle 2 , the larger the injection angle of the ultra-fine dry powder fire extinguishing agent, the larger the coverage area, and the smaller the injection amount of the ultra-fine dry powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com