Spherical explosive powder fire extinguisher

A technology of dry powder fire extinguishing agent and fire extinguisher, which is applied in fire prevention equipment, fire rescue, etc. It can solve the problems of hidden dangers to the life safety of fire extinguishers, unsatisfactory fire extinguishing effect of fire extinguishing agent, and inconspicuous fire extinguishing effect, so as to achieve remarkable fire extinguishing effect and overcome delivery position Inaccurate, good fire extinguishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

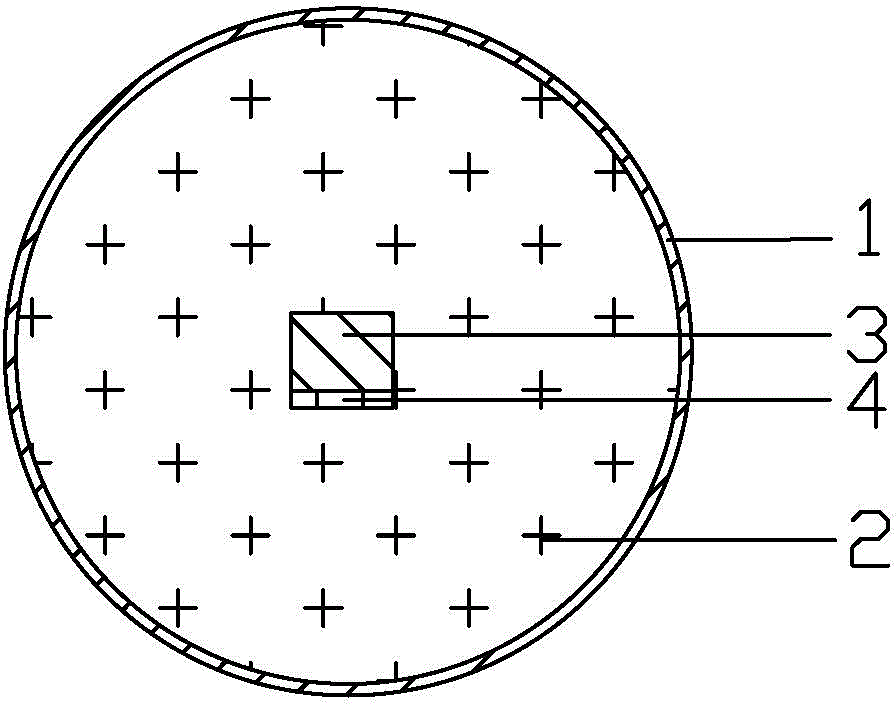

[0030] A spherical explosive dry powder fire extinguisher, such as figure 1 and figure 2 As shown, the spherical explosive dry powder fire extinguisher includes a spherical shell 1 and a dry powder fire extinguishing agent 2 filled in the spherical shell 1. The center of the spherical shell 1 is provided with an explosive package 3 and a device for controlling the explosion of the explosive package 3. The ignition device, the spherical housing 1 is composed of two hemispherical housings; the ignition device is a remote ignition device 4 arranged in the spherical housing 1 .

Embodiment 2

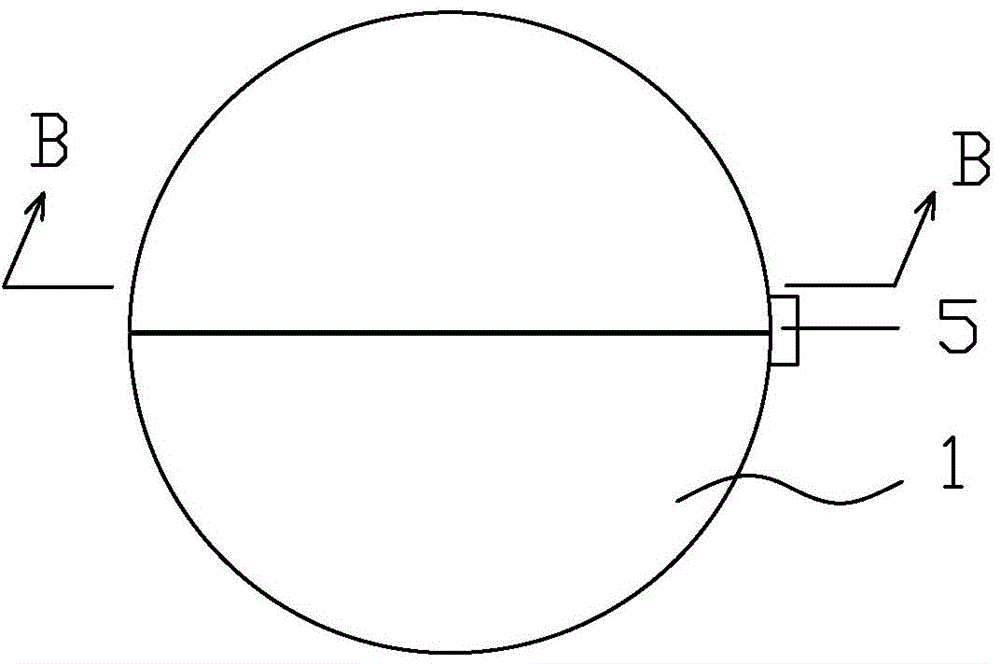

[0032] A spherical explosive dry powder fire extinguisher, such as image 3 and 4 As shown, the difference between this spherical explosive dry powder fire extinguisher and Embodiment 1 is that the ignition device also includes a temperature-controlled fuse 5 arranged outside the spherical casing 1 and connected to the explosive package 3 through a lead wire; the spherical casing 1 is made of 1.2mm thick coated paper.

Embodiment 3

[0034] A spherical explosive dry powder fire extinguisher, such as Figure 5 As shown, the difference between the spherical explosive dry powder fire extinguisher and the embodiment 2 is that the outer surface of the spherical shell 1 is provided with a remote control roller 6, and the movement of the remote control roller 6 is controlled by an external remote controller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com