Golf ball bag provided with automatically lifting club protection cover

A golf bag and automatic lifting technology, which is applied to golf club bags, golf balls, rackets, etc., can solve the problems of occupying outer barrel space, high cost, and small selection range for the surface smoothness of the club protective cover. Achieve the effect of improving grade, small space and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

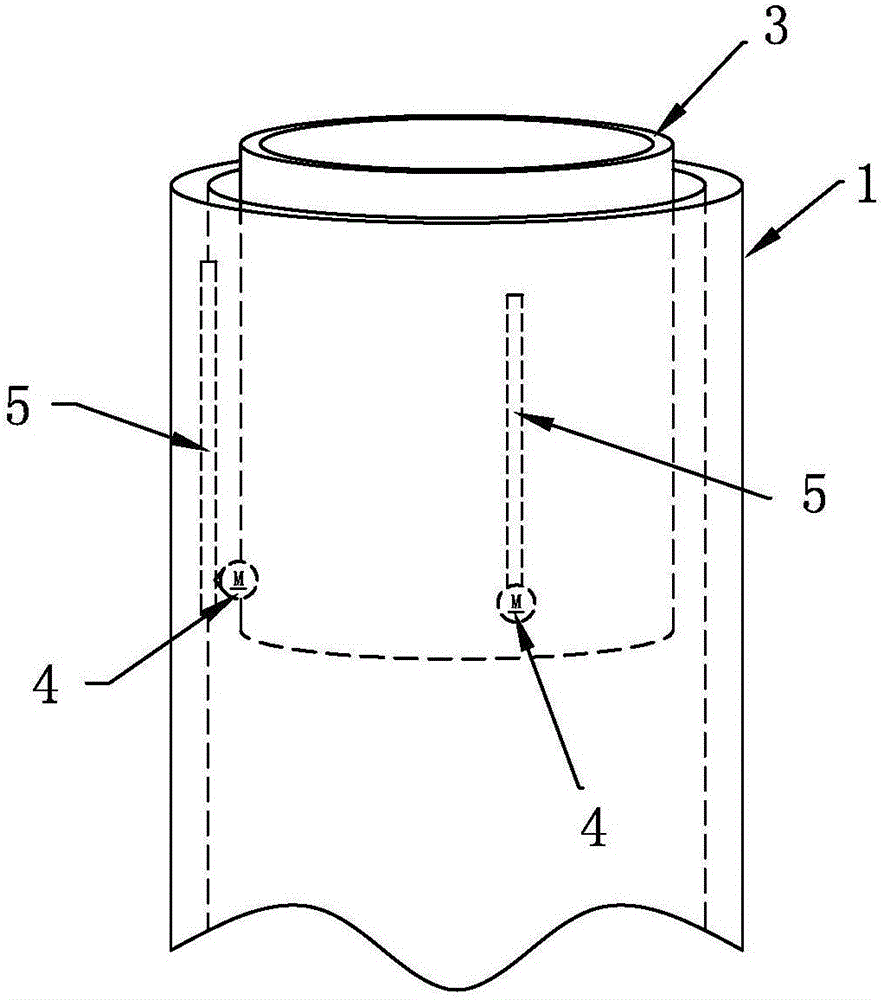

[0093] Such as Figure 7 , 10 As shown, the driving device 4 includes a motor 41 and a deceleration assembly 42, the motor 41 is fixedly connected to the lower part of the club protective cover 3, and the transmission mechanism 5 is composed of a rack 51 and a gear rack vertically arranged on the inner wall of the outer barrel 1. The gear 52 arranged on the outer wall of the club protective cover 3 and meshed with the rack 51 is formed, and the gear 52 is connected to the motor 41 through the reduction assembly 42 . When rising, the motor 41 drives the gear 52 to crawl upwards along the rack 51 through the reduction assembly 42. Since the rack 51 is fixed, there is a gap between the gear 52, the reduction assembly 42, the motor 41 and the club protective cover 3 It is rigidly connected (that is, the gear 52, the deceleration assembly 42, and the motor 41 have no displacement relative to the cue protection cover 3), therefore, the upward movement of the gear 52 also drives the...

Embodiment 2

[0095] Such as Figure 7 , 11 The difference from Embodiment 1 is that the transmission mechanism 5 in this embodiment is composed of a screw 53 and a nut 54 sleeved on the screw 53, and the screw 53 is vertically arranged on the outside of the club protective cover 3 Correspondingly, the nut 54 is fixedly connected to the bracket 43 provided on the inner wall of the tub 1, and the upper end of the screw rod 53 is connected to the motor 41 through the reduction assembly 42, and there is a rigid connection structure therebetween. Because the nut 54 is fixed, when rising, the motor 41 drives the screw rod 53 to rotate through the deceleration assembly 42, and the rotating screw rod 53 moves up relative to the nut 54 and drives the club protective cover 3 to move upward.

[0096] This structure hinders the appearance when the club protective cover 3 is moved up to the screw rod 53 and the deceleration assembly 42 is exposed outside.

Embodiment 3

[0098] Such as Figure 7 , 12 As shown, the difference from Embodiment 2 is that the screw rod 53 in this embodiment is vertically arranged on the inner side of the club protective cover 3, and correspondingly, the nut 54 is fixedly connected to the inner wall of the outer barrel 1. On the bracket 43 , the upper end of the screw rod 53 is connected with the driving motor 41 . The lifting principle of the club protective cover 3 in this embodiment is the same as that in Embodiment 2. Compared with Embodiment 2, it has the advantage of neat appearance and beautiful appearance. The reason is as follows: since the screw rod 53 is concealed in the club protective cover 3, no matter whether the club protective cover 3 rises or falls, the exposed screw rod 53 will not be seen from the outside. outside.

[0099] 2. The driving device 4 is set on the inner wall of the outer tub 1

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap