Pipeline Fluid Solid Impurity Double Hinge Rotor Online Crusher

A fluid-solid crusher technology, applied in the direction of grain processing, etc., can solve problems such as difficult to remove, rotor winding, etc., to achieve the effect of quick maintenance, stable operation, uniform and adjustable crushing particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

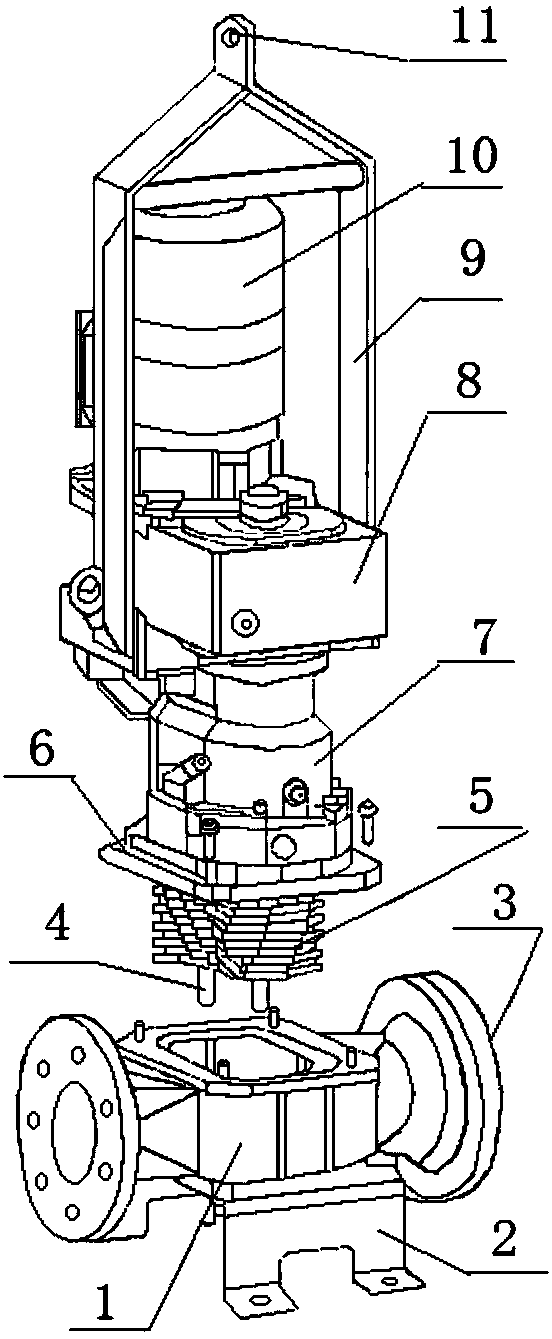

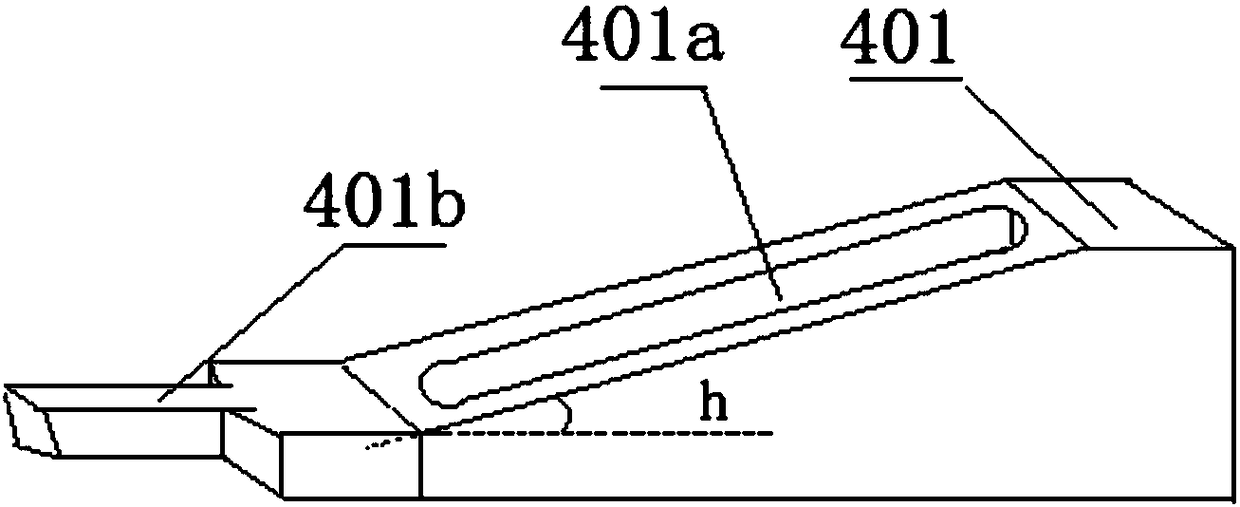

[0033] Embodiment 1: as attached figure 1 As shown, two rotors 5 whose outer edges are inserted into each other are installed in the casing 1, and the two rotors 5 are installed upright on their respective drive shafts 4, and the upper ends of the two drive shafts 4 are connected to the gearbox 8, and the casing 1 is horizontally Two liquid inlets and outlets 3 are arranged symmetrically and coaxially. The central axes of the two inlets and outlets 3 pass through the cutting position of the second rotor 5 horizontally. There are at least two coaxial cutting discs 501 with the same shape on the rotor 5. There are protruding hook-shaped teeth 501a on the outer edge of the disk 501, and the hook-shaped teeth 501a of two adjacent cutting disks 501 are installed in a staggered manner.

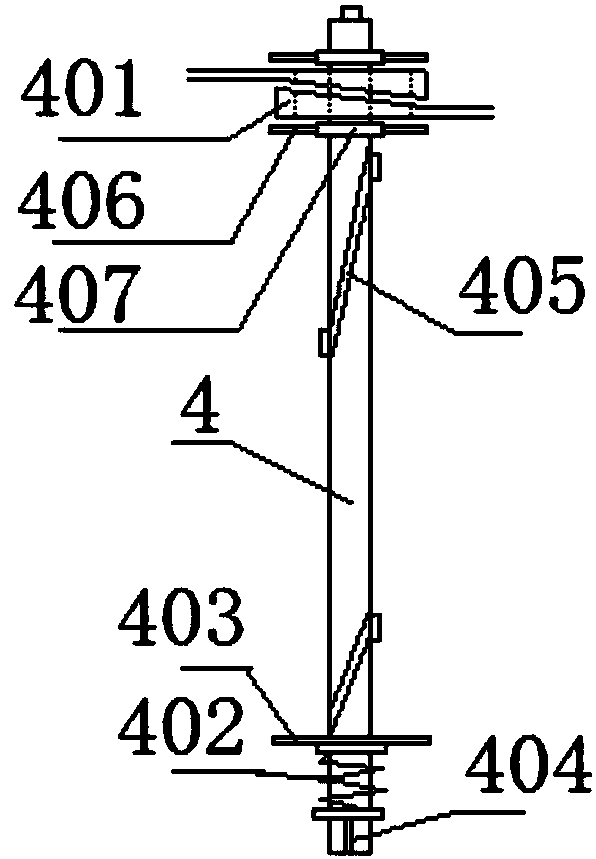

[0034] In the foregoing, as attached figure 2 As shown, there is a fixed shaft key 404 on the outer edge of the tail end of the drive shaft 4, and two pressure plates 406 are clamped and socketed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com